Hi all,

I was working on my RV-8 gear tower assemblies today and came across a potential issue with the outboard weldment on the right tower, WD-822-R-1.

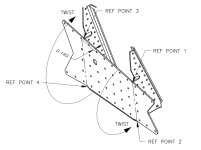

I was about to match drill the #12 holes for the AN3 bolts when I noticed that the corner angle wasn't sitting flush with everything cleco'd together. It looks as though the weldment underneath has not been squared up and induces a bend in the bulkhead when it's assembled together. (Photos attached)

Has anybody else had this issue?

(Still waiting on a reply from Vans)

Cheers!

I was working on my RV-8 gear tower assemblies today and came across a potential issue with the outboard weldment on the right tower, WD-822-R-1.

I was about to match drill the #12 holes for the AN3 bolts when I noticed that the corner angle wasn't sitting flush with everything cleco'd together. It looks as though the weldment underneath has not been squared up and induces a bend in the bulkhead when it's assembled together. (Photos attached)

Has anybody else had this issue?

(Still waiting on a reply from Vans)

Cheers!