I've got an RV-4 that I'm flying while building my -10. There has generally been s small amount of play in the stick particularly with the elevator control. I went out to pre flight after a few weeks off and it just felt like a slight bit more than before so I tore in to see if there is anything of concern.

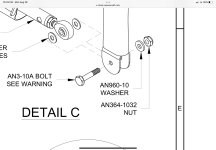

What I read in some other threads is the bushing at the stick could be a culprit and I've ruled that out. What it seems is potentially one of maybe 2 of the rod ends with a small amount of play in the joint itself. I took a video and happy to email it since I don't think the site supports more than pictures. Is it common for the rod ends to wear out and need replacement? Is there some leeway for the amount of play?

I'd say at top of stick it moves maybe 1/16th to 1/8th inch. Just enough for a little click fore and aft. The plane has 460 hours on it and was finished in 1991.

What I read in some other threads is the bushing at the stick could be a culprit and I've ruled that out. What it seems is potentially one of maybe 2 of the rod ends with a small amount of play in the joint itself. I took a video and happy to email it since I don't think the site supports more than pictures. Is it common for the rod ends to wear out and need replacement? Is there some leeway for the amount of play?

I'd say at top of stick it moves maybe 1/16th to 1/8th inch. Just enough for a little click fore and aft. The plane has 460 hours on it and was finished in 1991.