So I borrowed a friend's DRDT and got all of the required holes dimpled except the one closest to the forward edge on the middle nose rib. The skin to too long to fit in the DTRT and I've tried changing the angle every which way to sunday, but I can't get it to fit. I was considering ordering the pop rivet puller dimple set, but I've been told it makes crappy dimples. I did order the rivet set with the 3/16 hole for the gun and will make a "back rivet plate" style piece that will attach to the table wile a hole for the die similar to the one cleveland tool's sells.

How did everyone else tackle this?

How did everyone else tackle this?

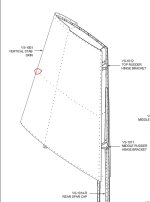

Attachments

Last edited: