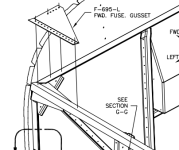

My F-695 Fwd Fuse Gusset doesn't seem to fit all that well. On the left side, my longeron twist looks to be really close to what it's supposed to be (sits snugly into the angle of the upper engine mount bracket), but because of how the top firewall stiffener fits against the longeron, the gusset doesn't nest against the stiffener where the stiffener and longeron meet. Am I good to bend the gusset to match, or do I need to address something else so I don't back myself into a corner with another part down the road?

The left side isn't horrible, but on the right side, it looks like my longeron is under twisted a bit (maybe between 1/32-1/16" gap between it and the engine mount bracket - although with a little pressure that gap closes up pretty well), causing the gusset to have a bigger gap. I'm trying to figure out how I deal with that given everything that is riveted together at this point.

The left side isn't horrible, but on the right side, it looks like my longeron is under twisted a bit (maybe between 1/32-1/16" gap between it and the engine mount bracket - although with a little pressure that gap closes up pretty well), causing the gusset to have a bigger gap. I'm trying to figure out how I deal with that given everything that is riveted together at this point.

Attachments

Last edited: