do I machine dimple the stainless steel firewall or die and punch it?

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

firewall Dimpling

- Thread starter Danflyboyman

- Start date

Carl Froehlich

Well Known Member

Dimple only. Use your big C frame. Do not try to machine countersink.

Carl

Carl

blaplante

Well Known Member

There is a specification either in the plans or in online rivet procedure sources that specifies the minimum thickness of metal to allow machine countersinking. Or just take a look at the head thickness of a countersunk rivet and compare to the firewall metal thickness.

The answer will be - you can't countersink the firewall. Besides that stainless will do a job on your countersink.

But best to know how this is decided, so when you come across something else, look at it and wonder which way to go.... you'll know what to do!

https://www.eaa.org/eaa/aircraft-building/builderresources/while-youre-building/building-articles/metal/flush-riveting-tips#:~:text=Countersinking%20is%20permitted%20only%20when,3%2F32"%20flush%20rivet.

"Countersinking is permitted only when the surface skin is thick enough to accommodate the cutout depression without enlarging the rivet hole." I wish some builders I'm cleaning up after would have followed this directive!

The answer will be - you can't countersink the firewall. Besides that stainless will do a job on your countersink.

But best to know how this is decided, so when you come across something else, look at it and wonder which way to go.... you'll know what to do!

https://www.eaa.org/eaa/aircraft-building/builderresources/while-youre-building/building-articles/metal/flush-riveting-tips#:~:text=Countersinking%20is%20permitted%20only%20when,3%2F32"%20flush%20rivet.

"Countersinking is permitted only when the surface skin is thick enough to accommodate the cutout depression without enlarging the rivet hole." I wish some builders I'm cleaning up after would have followed this directive!

There is a specification either in the plans or in online rivet procedure sources that specifies the minimum thickness of metal to allow machine countersinking.

<.040" - Dimple

>=.040" - Countersink

...and stainless is a bugger to drill, nvm countersinking...

<.040" - Dimple

>=.040" - Countersink

...and stainless is a bugger to drill, nvm countersinking...

I think section 5 in the manual mentions that machine countersinking .040 is acceptable, but still desirable to be dimple countersunk if possible.

.040 can be dimple countersunk nicely by impact Dimpling with a C frame, and a heavy mallet. Just hit a bit harder than you would, for most other skins.

<.040" - Dimple

>=.040" - Countersink

...and stainless is a bugger to drill, nvm countersinking...

Probably should quantify this statement by mentioning you're talking #3 rivets only.

BTW. It's doubtful the FW is thick enough to CS for anything but I don't know the OPs details.

Side note, Vans engineering. I was adapting the RV14 battery boxes to the firewall on my Rocket build. The 14 plans someone had shared with me called for #4 rivets but it was obvious the boxes were not 050 thick. Mic'd them and surprise. Vans had made them from 043, the minimum thickness to CS #4s. Would have lost that bet.

Last edited:

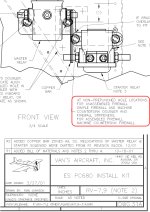

an RV-7,9 exception

Exception in the case of RV-7, 9 contactor hard points. And maybe other RVs.

Yea the firewall is too thin to machine countersink and it dimples easily even with pop rivet dimple dies but if you didn't have the foresight when assembling the firewall you can't dimple where there are stiffeners.

The attached RV-7, 9 dwg 31A instructs to machine countersink at the stiffeners in this case. Not an acceptable practice in general but these rivets only serve to keep the nutplates from spinning. (The rivet holes for the contactor doubler the note points to can be dimpled with a pop rivet die set even if the firewall is assembled because the doubler is not there yet.)

How to do the machine countersinking I haven't found a good way. The SS dulls a HSS cutter quickly and strips the grit off a Perma-Grit countersink cutter immediately. Some of my rivets are not quite flush and the last couple I a did a good-enough-to-get-by job with a pointed stone in a die grinder. If I had to do more I would try a pointy carbide burr.

BTW in the case of the PC680 battery box one could install the nutplates to the stiffeners firewall aft rather than to the battery box for easier removal in the future. One can also install an RV-14 battery box on an RV-7,9 using the RV-7, 9 steel angles.

.

Exception in the case of RV-7, 9 contactor hard points. And maybe other RVs.

Yea the firewall is too thin to machine countersink and it dimples easily even with pop rivet dimple dies but if you didn't have the foresight when assembling the firewall you can't dimple where there are stiffeners.

The attached RV-7, 9 dwg 31A instructs to machine countersink at the stiffeners in this case. Not an acceptable practice in general but these rivets only serve to keep the nutplates from spinning. (The rivet holes for the contactor doubler the note points to can be dimpled with a pop rivet die set even if the firewall is assembled because the doubler is not there yet.)

How to do the machine countersinking I haven't found a good way. The SS dulls a HSS cutter quickly and strips the grit off a Perma-Grit countersink cutter immediately. Some of my rivets are not quite flush and the last couple I a did a good-enough-to-get-by job with a pointed stone in a die grinder. If I had to do more I would try a pointy carbide burr.

BTW in the case of the PC680 battery box one could install the nutplates to the stiffeners firewall aft rather than to the battery box for easier removal in the future. One can also install an RV-14 battery box on an RV-7,9 using the RV-7, 9 steel angles.

.

Attachments

thanks for the information, the plans do say that when the tickness is under .040 do not machine dimple!!!

has anyone used AN470 rivet on the fire wall, are flush really necessary?

has anyone used AN470 rivet on the fire wall, are flush really necessary?

terminology is important

For clarity... machine dimple is an oxymoron. One machine countersinks or dimple countersinks to accommodate a flathead rivet or screw.

.

For clarity... machine dimple is an oxymoron. One machine countersinks or dimple countersinks to accommodate a flathead rivet or screw.

.

Carl Froehlich

Well Known Member

thanks for the information, the plans do say that when the tickness is under .040 do not machine dimple!!!

has anyone used AN470 rivet on the fire wall, are flush really necessary?

A couple of things:

- Flush rivets are either set in a dimple or a machine counter sink. There is no machine dimple. For the firewall these dimples are backed by aluminum that does get machined counter sunk to accept the dimples.

- You want flush rivets on the engine side of the firewall. This makes clean up a boatload easier.

Carl

... on the fire wall, are flush really necessary?

Numerous items are fastened to the firewall... engine mount, battery box, contactors, pressure sensor manifold, brake fluid reservoir... These items need a flat surface on which to bear.

.