Are you using tube radios too Walt?

I get it, I just think it's important that builders understand what they are getting into with full electronic fuel injection/ignitions systems.

I specialized in (and still do) repairing and installing avionics as a career, so I'm fully aware of the capabilities of modern panels and systems. Comparing modern glass panels to "FADEC" style Lyc's are 2 different things. Glass is now the standard for panels, and for good reason.

On the other hand, that is not the case at all for our little engines. I get it, everyone wants the latest and "greatest", but I've always been a bit conservative fellow, IE, my transition to a glass cockpit took a long time (grew up with VOR/ADF/charts) and that transition was slow and methodical until I had the confidence in the systems, and they matured to a point that reliability was proven (I still see a lot of old school airspeed and altimeters in glass aircraft because people don't fully trust electronics).

So here we have a bunch of amateur builder/mechanics, many with basically no aviation mechanical or electronic installation experience installing computers to keep the engine running. Make no mistake, these systems are experimental and flight time with most if not all, are in the hundreds/thousands of hours vs millions of hours with our 'old school' systems.

So, the reason I post all this is so new folks jumping into this hobby don't get the wrong idea and think they gotta have all this fancy stuff or they will be mocked for staying in the stone age.

I've had every electronic ignition system out there installed on my own aircraft except for the relatively new on the scene SDI. I fell into this 'trap as well as a new builder, even though I lived around aviation.

When I installed my new engine a few years ago I spec'd Bendix mags. I feel like I gained both reliability/repairability in the field, basically lost nothing in the process. Maybe I can't lean quite as far as I used to, saving maybe a gallon/hr, but these day I really don't care about a gal/hr, I'd rather go faster and not worry about all that other sh*t.

PS: I've had folks show up with a purchased airplane with EI/FI and had NO clue what was going on or system operation. One came in and was running only on the backup alternator because the primary had failed, he had no clue how close he was to things getting quite. Selling an airplane like this to an unsuspecting owner may have fatal consequences. I suspect even the builder didn't understand the system as many things were not done correctly.

Heck, we just had a recent thread of someone flying with a glass panel and then blamed the system when he tried to do aerobatics with the autopilot engaged!

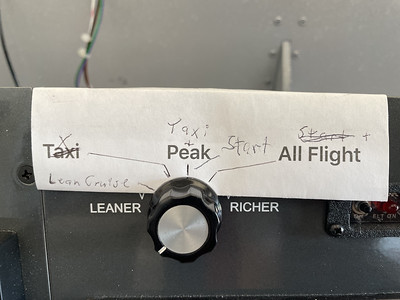

I'll never forget this picture I took of a "modern" mixture control in an RV:

OK movin on, Let's be safe out there!