Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crankshaft seal retaining plates

- Thread starter mack55

- Start date

A friend of mine had taken off in his Beech Super Musketeer and at initial climb out, the crankshaft seal blew out and covered the windscreen in oil pretty good. He was lucky enough to see through some clear spots to get it turned around and landed without rolling it up in a ball. When I did some research on the web, I found that Lycoming did offer some engines with crankshaft seal retaining plates that used a couple screws to hold them in place. No way was I going to drill into the case of my IO-540 V4A5 when I rebuilt it, but the thought of that happening to me scared me enough to fabricate my own retaining plates and install them using some of my left over, And Long Expired ("Oh my") Pro-Seal fuel tank sealant.

I'm not an A&P, but I've been around planes about 50 years. I've changed and helped to change a bunch of nose seals. Most recently on an R44 RII. If anyone is curious, THAT wasn't the least bit enjoyable. I don't recall ever working on one with retaining plates. If you have the option to put retainers on, I'd do it!

Bill

Bill

Some engines come with them and some don't. Don't know if Lycoming had those for newer engines or engines that could have a potential seal coming out. If you follow the seal instructions for installation during the overhaul process, it gets glued in there and should not be coming out. There is a rib on the seal and an indent in the case that is supposed to somewhat lock that into position. We use Pliobond 25 to glue it in place. I've done engines with plates and some without. If your case has the boss on the nose section, during the overhaul, you can get companies like Divco or CSI to machine it out and install heli-coils. Some older cases have the thin nose section and could not be machined for plates. Engines that have excessive blow-by usually like to blow oil out of the this seal.

Aden,Some engines come with them and some don't. Don't know if Lycoming had those for newer engines or engines that could have a potential seal coming out. If you follow the seal instructions for installation during the overhaul process, it gets glued in there and should not be coming out. There is a rib on the seal and an indent in the case that is supposed to somewhat lock that into position. We use Pliobond 25 to glue it in place. I've done engines with plates and some without. If your case has the boss on the nose section, during the overhaul, you can get companies like Divco or CSI to machine it out and install heli-coils. Some older cases have the thin nose section and could not be machined for plates. Engines that have excessive blow-by usually like to blow oil out of the this seal.

In the pictures at the top of this post you can see my case and the holes for the retaining plates. I used Permatex® Optimum MaxFlex Black (P/N 27037) as recommended sealant. Pliobond 25 was also acceptable. My question is should I buy retaining plates and install as well?? Used ones seem to be around $150 which at this point I am past the threshold of pain. Would rather install now than later. I just put my prop on for a trial fit and I would like to only do that one more time

You built an airplane. Why not make a set of the plates??? Let me look on my hard drives [total of 15 Gigabytes]. I seem to remember getting a drawing with dimensions from someone to make them. My memory "used" to be a steel trap. As I have aged, it's now a steel sieve!Aden,

In the pictures at the top of this post you can see my case and the holes for the retaining plates. I used Permatex® Optimum MaxFlex Black (P/N 27037) as recommended sealant. Pliobond 25 was also acceptable. My question is should I buy retaining plates and install as well?? Used ones seem to be around $150 which at this point I am past the threshold of pain. Would rather install now than later. I just put my prop on for a trial fit and I would like to only do that one more time

Back before first flight in 1997, I purchased an engine core to rebuild for my RV-6. IT had retaining plates. I sent the case out to get lapped and line bored. It came back with the screw holes filled in so retaining plates were not need. The engine was assembled and ran without retaining plates for something like 2,800 hours.

Just my opinion, the adhesive used on the seals is strong enough without the retaining plates. Retaining plates are just parts that are not needed when the engine is assembled correctly.

Just my opinion, the adhesive used on the seals is strong enough without the retaining plates. Retaining plates are just parts that are not needed when the engine is assembled correctly.

If the seal that is installed does not have a raised ring on the od of the seal that corresponds to a machined groove in the nose seal bore then I would install the plates. If the seal has a raised ring that will fit into the corresponding ring machined in the nose seal bore then plates are not necessary, but it won't hurt anything to install them. Good Luck, Mahlon

I posted a picture of my case above. Does this have the machined groove you were talking about? I couldn't find one of my seal before installing..If the seal that is installed does not have a raised ring on the od of the seal that corresponds to a machined groove in the nose seal bore then I would install the plates. If the seal has a raised ring that will fit into the corresponding ring machined in the nose seal bore then plates are not necessary, but it won't hurt anything to install them. Good Luck, Mahlon

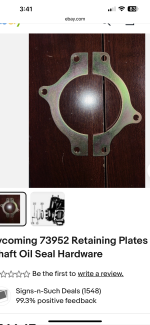

I had seal issues when I first got the 6a. I put a new seal in and installed the retainers (had to drill and tap the cases) issues went away that was 14 yrs ago. I water jetted out 100 sets of these, I believe I have a few sets. See PicDo I need to install the crankshaft seal retaining plates if I installed the solid crankshaft seal PN LW-13792 according to service instruction 1324D?

If so, anyone have some for sale?

Attachments

Last edited:

Skykingbob

Well Known Member

Mack,

First of all the way your holes are drilled probably won't accommodate the plates in the photo you have above. The Lycon plates you show require two holes in the top and bottom as well as the holes on each side (6 holes total). You only seem to have a total of 4 holes in yours and they don't appear to be indexed properly as far as I can tell. Unless you make a custom retainer as one poster mentioned I think you are out of luck and may just need to go with a good glue job.....which really seems sufficient.

Like some have already stated, some engines don't have the option unless you are willing to drill them IAW a service instructions.....if you can find them. My experience was

in an RV8 with a IO-360 Angle Valve 200HP model. I was flying between Boone, AR and OKC. Somewhere the crank seal pushed out. I started losing oil but I was unaware of it

since none came on the windscreen. I landed after the approximately 1.5 hour flight to see oil dripping off the side, front, and bottom of the cowl (see pics). I estimate I lost about 2 quarts of

oil but did not have any adverse engine instrument readings. The shop at Sundance reinstalled the seal (it was in fine shape) but noted the glue used to retain the seal was done very poorly.

The saving grace I believe that hindered me getting a windscreen full of oil was the fact that the airplane had Lightspeed EI and the two timing modules that mount under the ring gear limited how far the seal was able to come out......it may have been a lot worse! My RV8 build has the XIO-360 that has the holes drilled and retainer plates which I decided to install just for extra comfort.....don't think I would venture into drilling them in there if they weren't already there.

Good luck!

First of all the way your holes are drilled probably won't accommodate the plates in the photo you have above. The Lycon plates you show require two holes in the top and bottom as well as the holes on each side (6 holes total). You only seem to have a total of 4 holes in yours and they don't appear to be indexed properly as far as I can tell. Unless you make a custom retainer as one poster mentioned I think you are out of luck and may just need to go with a good glue job.....which really seems sufficient.

Like some have already stated, some engines don't have the option unless you are willing to drill them IAW a service instructions.....if you can find them. My experience was

in an RV8 with a IO-360 Angle Valve 200HP model. I was flying between Boone, AR and OKC. Somewhere the crank seal pushed out. I started losing oil but I was unaware of it

since none came on the windscreen. I landed after the approximately 1.5 hour flight to see oil dripping off the side, front, and bottom of the cowl (see pics). I estimate I lost about 2 quarts of

oil but did not have any adverse engine instrument readings. The shop at Sundance reinstalled the seal (it was in fine shape) but noted the glue used to retain the seal was done very poorly.

The saving grace I believe that hindered me getting a windscreen full of oil was the fact that the airplane had Lightspeed EI and the two timing modules that mount under the ring gear limited how far the seal was able to come out......it may have been a lot worse! My RV8 build has the XIO-360 that has the holes drilled and retainer plates which I decided to install just for extra comfort.....don't think I would venture into drilling them in there if they weren't already there.

Good luck!

Your lucky! thanks for sharingMack,

First of all the way your holes are drilled probably won't accommodate the plates in the photo you have above. The Lycon plates you show require two holes in the top and bottom as well as the holes on each side (6 holes total). You only seem to have a total of 4 holes in yours and they don't appear to be indexed properly as far as I can tell. Unless you make a custom retainer as one poster mentioned I think you are out of luck and may just need to go with a good glue job.....which really seems sufficient.

Like some have already stated, some engines don't have the option unless you are willing to drill them IAW a service instructions.....if you can find them. My experience was

in an RV8 with a IO-360 Angle Valve 200HP model. I was flying between Boone, AR and OKC. Somewhere the crank seal pushed out. I started losing oil but I was unaware of it

since none came on the windscreen. I landed after the approximately 1.5 hour flight to see oil dripping off the side, front, and bottom of the cowl (see pics). I estimate I lost about 2 quarts of

oil but did not have any adverse engine instrument readings. The shop at Sundance reinstalled the seal (it was in fine shape) but noted the glue used to retain the seal was done very poorly.

The saving grace I believe that hindered me getting a windscreen full of oil was the fact that the airplane had Lightspeed EI and the two timing modules that mount under the ring gear limited how far the seal was able to come out......it may have been a lot worse! My RV8 build has the XIO-360 that has the holes drilled and retainer plates which I decided to install just for extra comfort.....don't think I would venture into drilling them in there if they weren't already there.

Good luck!

View attachment 65358View attachment 65360View attachment 65359

Thanks Rabbit, looks like my case supports a different style retainer.I had seal issues when I first got the 6a. I put a new seal in and installed the retainers (had to drill and tap the cases) issues went away that was 14 yrs ago. I water jetted out 100 sets of these, I believe I have a few sets. See Pic

Cardinal767

Member

Mack55’s picture shows why there’s very little pressure pushing on the seal and why a properly installed seal last a long time without a retainer. The area behind the seal and forward of the main bearing is open to the crankcase. I’ve only seen a couple of times where the seal was pushed out by crankcase pressure. Once from a breather hose crimped and another from a home built separator on the breather hose. Both caused major oil loss because the case pressure had no other way to escape and took the oil coming off the main bearing with it.