ColoCardinal

Well Known Member

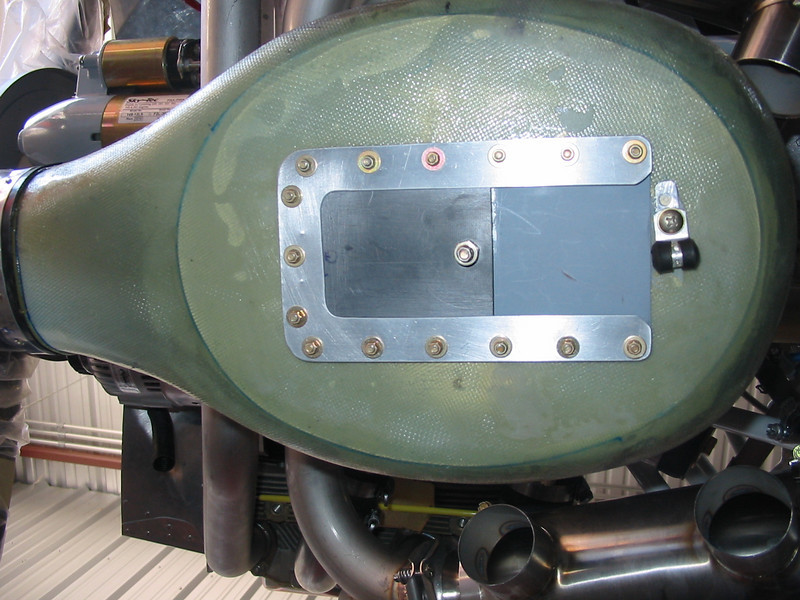

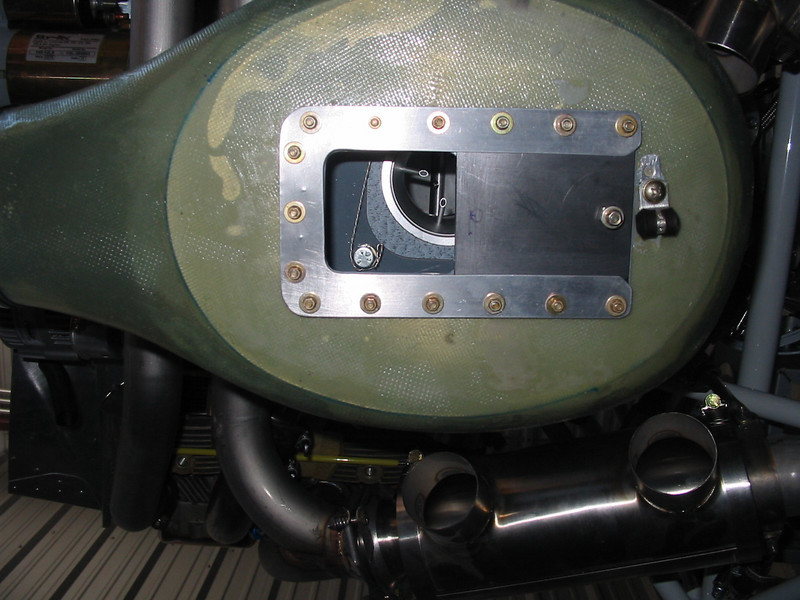

I'm beginning the work on my Van's vertical induction cowling.

The first question / concern I have regards the alternate air system. I'm not excited by the system supplied with the kit. An alternate air source is important enough on every GA plane I've ever flown that it's tested before every flight. One that requires a partial dissasembly of the aircraft to "reset" doesn't seem safe to me. Has anyone cooked up a better system they would like to share?

A (distant) second question - has anyone used the hinge pin system also used by Lancair on the IV-P. It has a threaded end and leaves only a .20" hole in the front of the cowl. No cover plates and very simple.

The first question / concern I have regards the alternate air system. I'm not excited by the system supplied with the kit. An alternate air source is important enough on every GA plane I've ever flown that it's tested before every flight. One that requires a partial dissasembly of the aircraft to "reset" doesn't seem safe to me. Has anyone cooked up a better system they would like to share?

A (distant) second question - has anyone used the hinge pin system also used by Lancair on the IV-P. It has a threaded end and leaves only a .20" hole in the front of the cowl. No cover plates and very simple.