My Cowling is fitted on and I'm really pleased with the fit. I've measured it dozens of time and the front of the cowl is exactly where it needs to be based on my 3 blade Hartzell prop.

Here's my new issue.....the forward edges of the left and right air ramps are not even close to what the plans show they should be. Way too long. I can deal with the right side by shortening it as required. The real issue is the left air ramp. I can't shorten it because of the scat inlet hole is already at the forward edge of the ramp.

Has anyone ever reduced the aft edge of the lower cowl inlet distances to make it all fit? As it is the Scat inlet would have to be 3/4 of an inch aft or the aft edge of the lower left cowl inlet would need to be reduced by 3/4 of an inch.

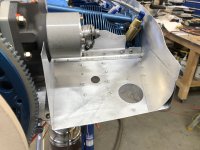

In the attached photos one shows a tiny blue mark. This would be where the forward edge of the scat hole would be as is. The second photo show how far the #2 baffle extends forward in to the cowl. This is AFTER the initial cut the plans call for. Am I missing something obvious????

Thanks again

Here's my new issue.....the forward edges of the left and right air ramps are not even close to what the plans show they should be. Way too long. I can deal with the right side by shortening it as required. The real issue is the left air ramp. I can't shorten it because of the scat inlet hole is already at the forward edge of the ramp.

Has anyone ever reduced the aft edge of the lower cowl inlet distances to make it all fit? As it is the Scat inlet would have to be 3/4 of an inch aft or the aft edge of the lower left cowl inlet would need to be reduced by 3/4 of an inch.

In the attached photos one shows a tiny blue mark. This would be where the forward edge of the scat hole would be as is. The second photo show how far the #2 baffle extends forward in to the cowl. This is AFTER the initial cut the plans call for. Am I missing something obvious????

Thanks again