BobbyLucas

Well Known Member

So we fired up our engine for the first time this weekend, and it did not go well. To start with, I had way too much throttle because I didn't know 50% throttle is only a couple of centimeters of throttle-handle travel. After the fact, I found the G3X screen that showed the actual throttle %.

When the engine finally started, I realized the throttle was too high and pulled it back. There were a few seconds of smooth running, but for the most part, it was shaking pretty violently, so I assumed at least one cylinder was not firing. The Lane A light started blinking and I shut it down and have not tried to restart it since.

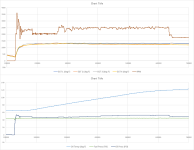

I finally figured out how to get the G3x logs this morning and confirmed there's an issue with cyl3 and possibly 4.

The fuse box shows all green lights, at least when the engine isn't running. All cables into and out of the fuse box, EMS, and HIC seem to be fully seated. I guess I can pull them all and make sure each pin is fully seated. Spark plugs are torqued.

Any other ideas, other than the obvious digging into the manuals and calling Van's?

When the engine finally started, I realized the throttle was too high and pulled it back. There were a few seconds of smooth running, but for the most part, it was shaking pretty violently, so I assumed at least one cylinder was not firing. The Lane A light started blinking and I shut it down and have not tried to restart it since.

I finally figured out how to get the G3x logs this morning and confirmed there's an issue with cyl3 and possibly 4.

The fuse box shows all green lights, at least when the engine isn't running. All cables into and out of the fuse box, EMS, and HIC seem to be fully seated. I guess I can pull them all and make sure each pin is fully seated. Spark plugs are torqued.

Any other ideas, other than the obvious digging into the manuals and calling Van's?