Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

470AD4-5 vs 470AD4-6 here?

- Thread starter md9680

- Start date

I have found times when I needed to upsize a rivet. There is no issue in doing so, as long as you are able to properly set the rivet. Just make sure the parts are properly seated before upsizing. That is, no burs, or junk holding the parts ever so slightly apart.

Yeah, it all fit pretty snuggly but I found the shop head to be a bit short as well as undersized. I was hoping to find others that may have had issues with the -5s here.I have found times when I needed to upsize a rivet. There is no issue in doing so, as long as you are able to properly set the rivet. Just make sure the parts are properly seated before upsizing. That is, no burs, or junk holding the parts ever so slightly apart.

D-Dubya

Well Known Member

Sometimes, the rivet sizes called out are right on the edge of being too long or too short. Don't sweat it if you need to make a change, as long as the holes are prepared correctly and the rivets are set properly. Do you have one of the gauges shown on the right in this photo? It's a good indicator to see if the rivet size is correct before you set it. When I first started building, I had one that came with the set, but I had no idea how to use it. Bob Avery with Avery Tools explained how to use it over the phone one day.

Thanks for the advice. It's starting to gnaw on me, though, that the AD4-5s were so small in my gauge. I'm going to drill them out and check the fit of the pieces. Maybe I didn't take enough off the doubler angle to get a close enough fit to the spar. I've gotten pretty good at drilling out rivets without damaging holes...(sigh!).Sometimes, the rivet sizes called out are right on the edge of being too long or too short. Don't sweat it if you need to make a change, as long as the holes are prepared correctly and the rivets are set properly. Do you have one of the gauges shown on the right in this photo? It's a good indicator to see if the rivet size is correct before you set it. When I first started building, I had one that came with the set, but I had no idea how to use it. Bob Avery with Avery Tools explained how to use it over the phone one day.

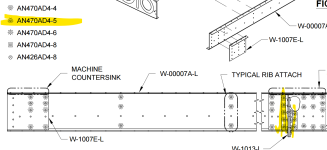

View attachment 64923

There is the rule of thumb, 1.5 diameter/.5 diameter, and there is the Mil spec.Thanks for the advice. It's starting to gnaw on me, though, that the AD4-5s were so small in my gauge. I'm going to drill them out and check the fit of the pieces. Maybe I didn't take enough off the doubler angle to get a close enough fit to the spar. I've gotten pretty good at drilling out rivets without damaging holes...(sigh!).

Rivet callouts in the plans are generally done to assure a shop head meets the mill spec.

There are two reasons for this

One is that as already mentioned, sometimes the ideal rivet length falls somewhere between two specific sizes. If, during prototyping, it was determined that there would be a high risk for inexperience builders to Get poor results when setting the rivets, and then be in a situation of attempting to remove a rivet, especially if it is in a high load path location, and then having a messed up hole that they are calling tech-support for assistance in resolving.

Second reason being if the shorter rivet allows for meeting the mil spec requirement for the dimensions of a shop head, it is a no-brainer to use that if there is any risk at all in setting the rivet to be more difficult if it was longer.

There is no strength difference between a properly set rivet that meets the mill spec versus one that meets the rule of thumb dimension.

A PDF copy of the mill spec document can be found in the FAQ section of vans website.

Jonnyb

Well Known Member

Check if the manufactured head dimensions meets Mil Spec first. If it does why drill them out?Thanks for the advice. It's starting to gnaw on me, though, that the AD4-5s were so small in my gauge. I'm going to drill them out and check the fit of the pieces. Maybe I didn't take enough off the doubler angle to get a close enough fit to the spar. I've gotten pretty good at drilling out rivets without damaging holes...(sigh!).

I think you mean shop head dimensions, but I agree.Check if the manufactured head dimensions meets Mil Spec first. If it does why drill them out?

Jonnyb

Well Known Member

Sorry, yep, I mean shop head.I think you mean shop head dimensions, but I agree.

I agreeNothing wrong with cutting a 6 down to a 5.5. My rivet cutter got a lot of use on 470 rivets.

In the same context as there being nothing wrong with using a 5 instead of a cut down 6, if the resulting shop head meets the dimension minimums in the Mil spec.