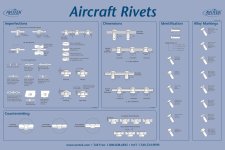

So I used my Cleaveland squeezer 1/8” cup set (yes definitely not the 3/32) and it left rings around my ad470-7 rivets like in the pic….they don’t look bad and the camera makes them look worse but anyone else get this? I see online a lot of rivets look untouched after riveting. Cheers.

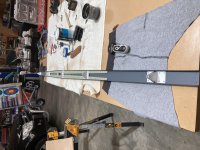

Plus that rotten last rivet that I munched and drilled out in a rush without thinking carefully has made that hole ugly. I touched up with primer and put another rivet in there….then took it out…thought I better check that hole to find I have ovalled it to .150. I am assuming I’ll need to drill and fit a 5/32 rivet….edge distance no issue on that piece. Comments?

Plus that rotten last rivet that I munched and drilled out in a rush without thinking carefully has made that hole ugly. I touched up with primer and put another rivet in there….then took it out…thought I better check that hole to find I have ovalled it to .150. I am assuming I’ll need to drill and fit a 5/32 rivet….edge distance no issue on that piece. Comments?