Thanks for the water puddle drying in the bottom DanH, makes sense but never seen water pooled there.

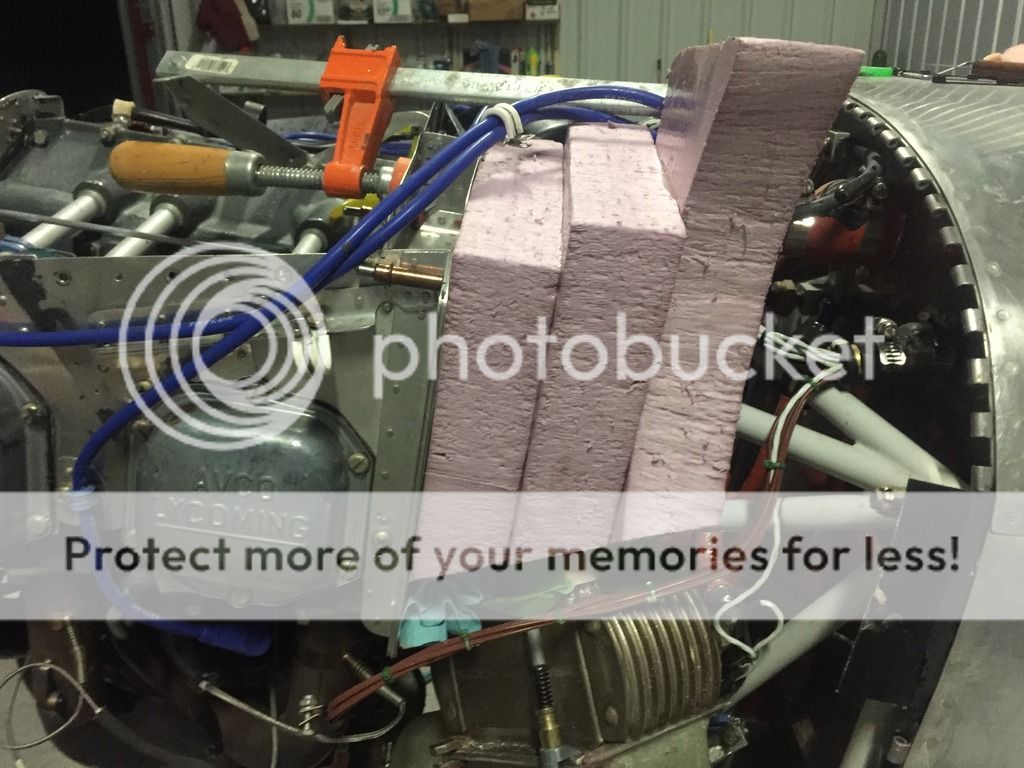

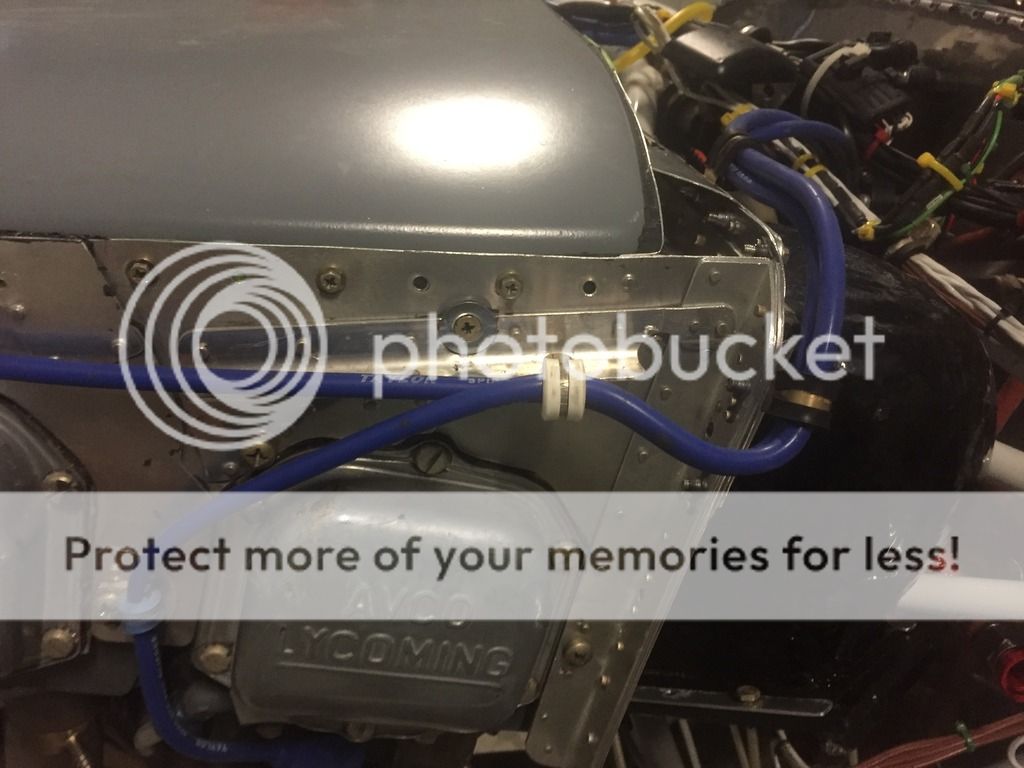

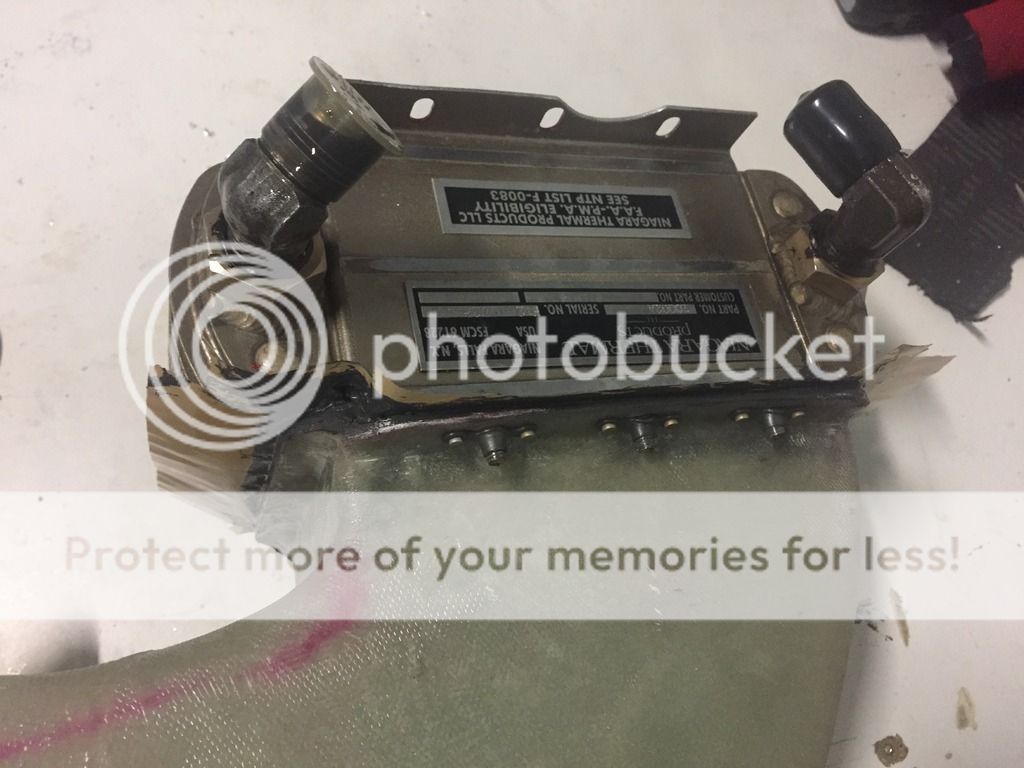

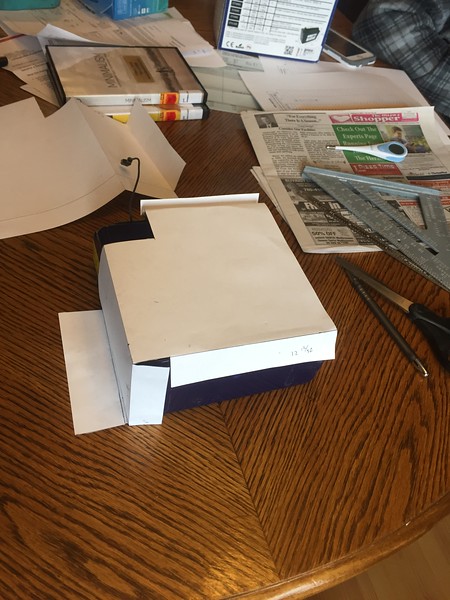

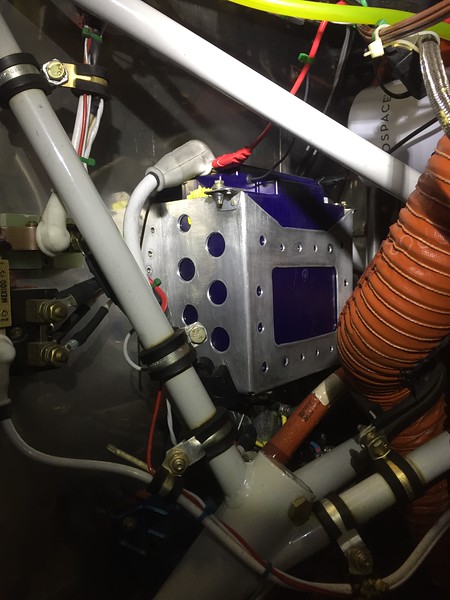

Mark, I'm still wrapping my head around this interior duct although the bluff body is something else to look into. My current oil cooler duct in progress shouldn't affect my CHT's as far as I know, my cowling outlet will remain unchanged for now so lower cowling pressures should remain the same. The interior oil cooler duct outlet pressure reference lower cowling pressure may take some tweaking to get oil temps where I want, we'll see.

I'm also trying to keep cowling removal installation simple and easy, just in case I ever paint this thing.

Part of what is driving me is the reduced cowling exit area some people have achieved. My cowling exit has been fixed at about 35 sq inches and working well the past 60 hours or so, I was amazed a few curves allowed me to keep the same cooling with a smaller exit and 2 extra knots!

Mark, I'm still wrapping my head around this interior duct although the bluff body is something else to look into. My current oil cooler duct in progress shouldn't affect my CHT's as far as I know, my cowling outlet will remain unchanged for now so lower cowling pressures should remain the same. The interior oil cooler duct outlet pressure reference lower cowling pressure may take some tweaking to get oil temps where I want, we'll see.

I'm also trying to keep cowling removal installation simple and easy, just in case I ever paint this thing.

Part of what is driving me is the reduced cowling exit area some people have achieved. My cowling exit has been fixed at about 35 sq inches and working well the past 60 hours or so, I was amazed a few curves allowed me to keep the same cooling with a smaller exit and 2 extra knots!