Walt

Well Known Member

To be honest folks I'm really getting tired of finding these bad/cracked flares made with substandard tools. Making new fuel lines for already completed aircraft is not my idea of fun. Please folks, fuel lines are really important, how about using the right tools, get someone to show you how to do it properly and inspect your work (using a magnifier) before installing a bunch of defective fuel lines, please do if for me

These are off a customers RV10, found in the tunnel.

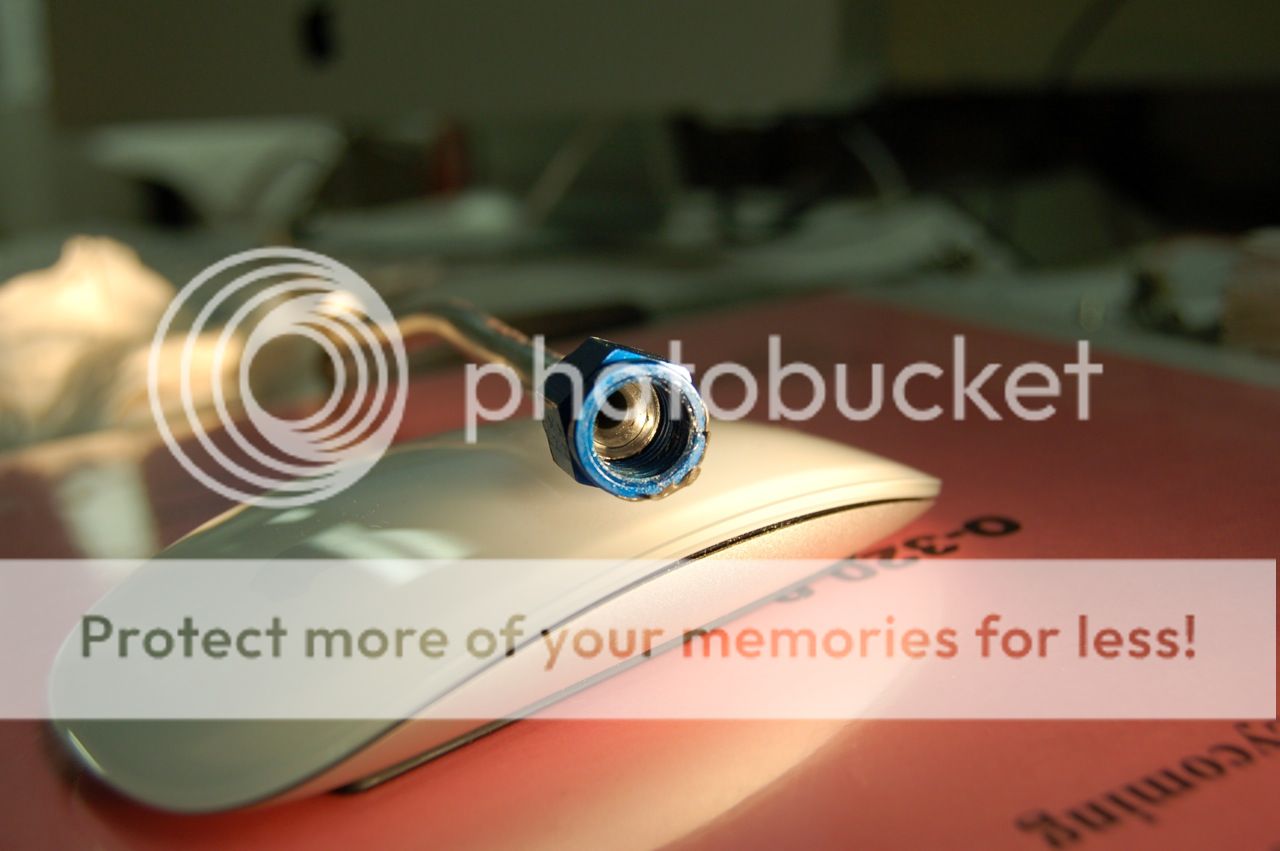

Cracked Flares

You can see the crack here at about 2 oclock on the lower edge of the flare!

Cracked from 12 to 2 o clock

Left is good flare, Right is BAD flare

This is an example I grabbed from my junk drawer to show what an acceptable flare should look like.

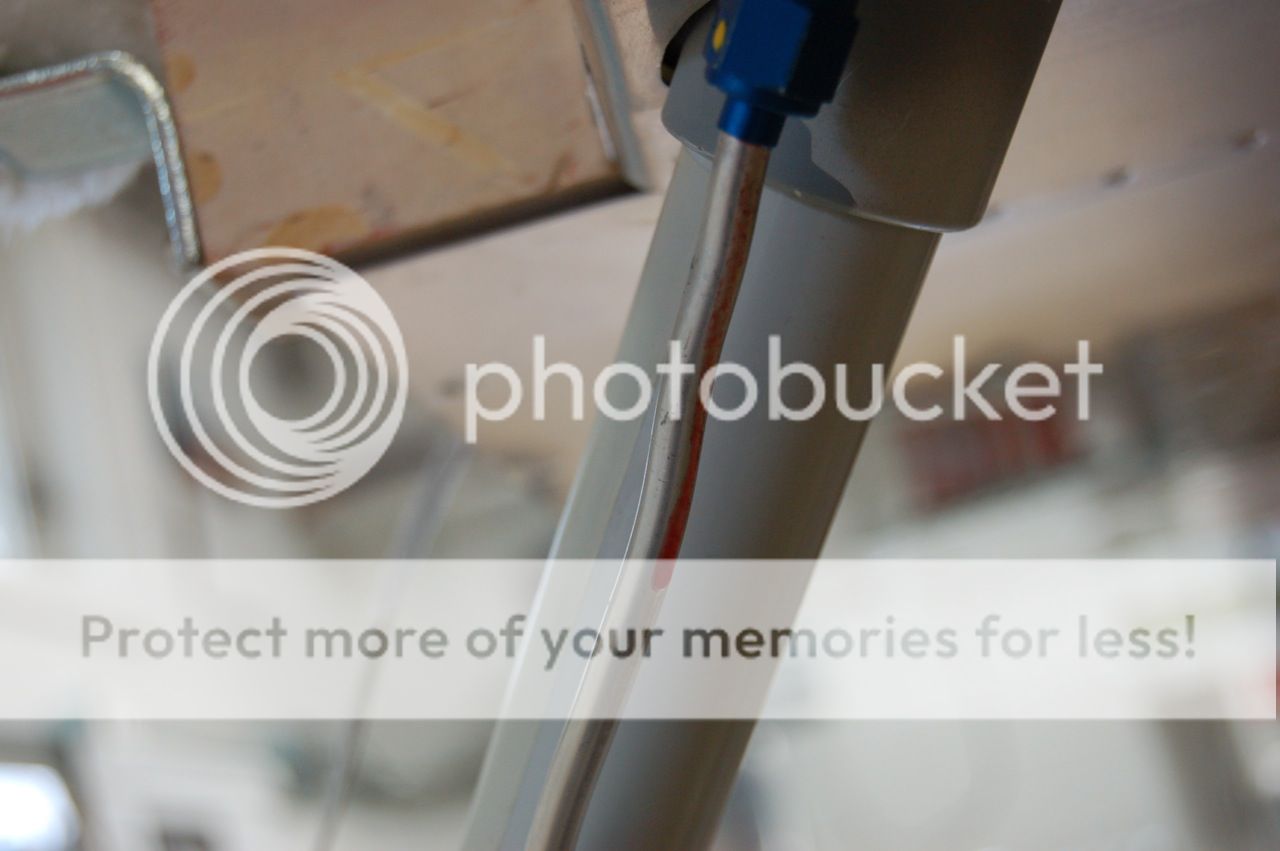

These are off a customers RV10, found in the tunnel.

Cracked Flares

You can see the crack here at about 2 oclock on the lower edge of the flare!

Cracked from 12 to 2 o clock

Left is good flare, Right is BAD flare

This is an example I grabbed from my junk drawer to show what an acceptable flare should look like.

Last edited: