Tumper

Well Known Member

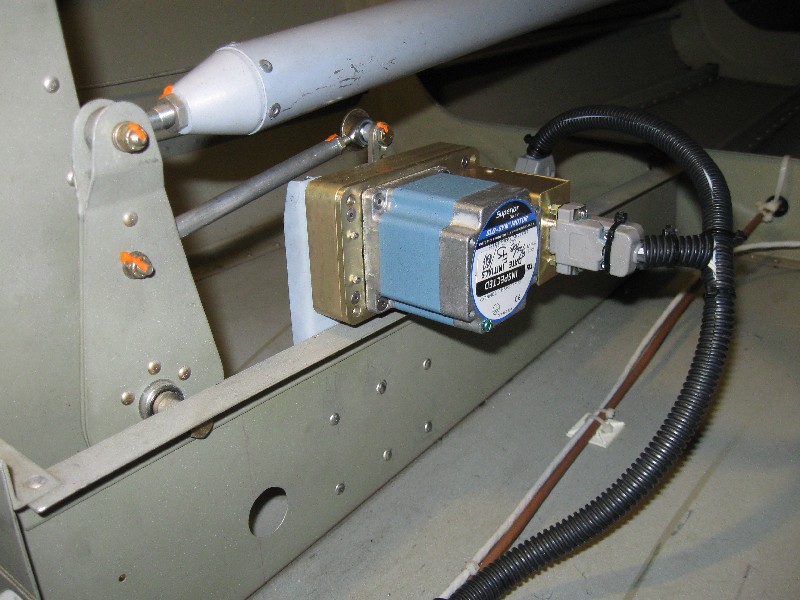

I have a question for you guys that have installed a TruTrak pitch servo. Mounting the servo is pretty straight forward (I think). But as you can see from the picture, the mounting has placed the linkage more or less in line with the bell crank. The diagram indicates the linkage should go on the right side of the bell crank, how did you accomplish that? I guess I could put spacers between the servo and the mount to move the servo to the left, and then attach the linkage to the left side of the bell crank.

Also I have a build video from George Orndorff where he mounts the strobe power supply next to the pitch servo. Has anyone mounted the strobe power supply and pitch servo that close together with/without electrical interference?

Thanks,

Also I have a build video from George Orndorff where he mounts the strobe power supply next to the pitch servo. Has anyone mounted the strobe power supply and pitch servo that close together with/without electrical interference?

Thanks,