Well, we now have a fuselage-looking-thing sitting in our hangar with all the skins (below the longerons) clecoed in place (and those aft of the cockpit actually riveted!) , and before I forget some of the little details, I thought I?d out them down in case they might help someone following in our wake?.

1) As has been noted before, be very suspicious about the fit of the bulkheads. We had several that fit well, and a couple that fit poorly. Plan to adjust or re-flange as required. We didn?t feel they were all bad enough to re-flange, but some just don?t work well.

2) We decided to go with Randy Lervold?s suggestion to use -3 rivets at 1? spacing on the longerons instead of -4 at 2?. As randy pointed out, the -3 rivets are used on later RV?s, and the closer spacing will help the skins lay down better.

3) This is old news to anyone who has riveted a slow-build fuselage, but especially on the narrow -3, it was very easy to cleco on the first side and reach across the jig to buck those rivets before clecoing on the other side. This way, the Bucker only has to live inside the cave for half the time.

4) After riveting the skins aft of the F-305, we fit the cockpit floor skins, followed by the forward bottom skin, and then did the side panels. This seemed pretty efficient, and we only had to disassemble things a couple of times. We fabricated the forward floor ribs (the triangular-shaped ones that also brace the firewall in the center) and drilled them to the forward floor. Since they help to define the shape of that floor skin, I felt it would give us a truer location for the outside and aft drill holes, and that seemed to work well.

5) When fitting the forward side skins, we measured and predrilled all the rivet holes in the skeleton first (stringers, longerons, and bulkheads), then back drilled through the skins, with one person putting backing the skin from the outside with a small piece of wood, then clecoing the holes. It probably took us an hour per side ? very fast.

6) We fit the side skins and drilled them to the skeleton before trimming them at all (except for cutting a rectangular hole for the rear spar carry-through. We removed the false main spar stubs, cockpit floor skins (because of the overhang) and all clecos that were in the way of the skin as we drilled. We first drilled it to the longeron between the F-303 and F-305. This pretty much fixed the skin in position, and we proceeded to drill out way up the bulkheads and along the stringers. The fit was excellent.

7) Locating the aft spar hole in the side skin was easier than I had thought. I was thinking that it would be a nightmare due to nothing being square, but since we worked with the side skins when they were still rectangular, it was a very simple measurement horizontally aft from the firewall and up (in the jig) from the longerons. Took a minute, and both sides located perfectly ? I am rarely that lucky!

8) After drilling the rectangular-shaped blank for the side skins and clecoing it in place, we marked it for trimming, removed it, and cut it to shape. Having traced the cut-out for the aileron pushrod hole before removing it, we cut that, then clecoed it back in place, did final trimming, and cut out the hole for the main spar using a Uni-bit to start a hole, then a nibbler to enlarge it, and finally an angle die-grinder with a sanding disc on it to make it to final size.

9) There is what we call ?the really ugly joint? right where the F-305 meets the stringer coming forward, the stringer coming aft (at the top of the seat rib), and the skin. It looked like it was going to be a real nightmare, thick and full of things that didn?t stack quite right ? but with the skin on, it is far better. I still haven?t figured out the rivets there, but I now at least believe there is a glimmer of hope it will work out. Building is like that ? you go from ?it?s impossible? to ?well, maybe? to ?that?s only half bad? to ?it?s strong, and no one will ever notice?? in the process of fabrication!

10) I didn?t see any drawing call-outs for a line of rivets along the bottom edge of the outside seat ribs (to hold it to the skin), so I drilled 2?-spaced holes for -4 rivets. They?ll be hidden by the wing roots anyway. It really helped the final fit!

11) I had to carve away some wood off the outside of the firewall uprights on the jig to allow the skin to lie against the firewall flange. Sawdust mixed with aluminum dust ? going to have to clean up the shop!

12) Since the aft side skins were already drilled and clecoed to the F-305 bulkhead flange, it was easy to match-drill this line of holes to the forward side skin. I then laid out the second column of rivets for that overlap joint based on that row. Worked really slick.

13) Next up is staring at it awhile to see where we need a few more rivets, fitting the exhaust tunnel sides, then disassembly for de-burring, dimpling, countersinking, etc. in prep for riveting. I hate taking things apart once it looks like something ? but that?s the name of the game!

A few pictures :

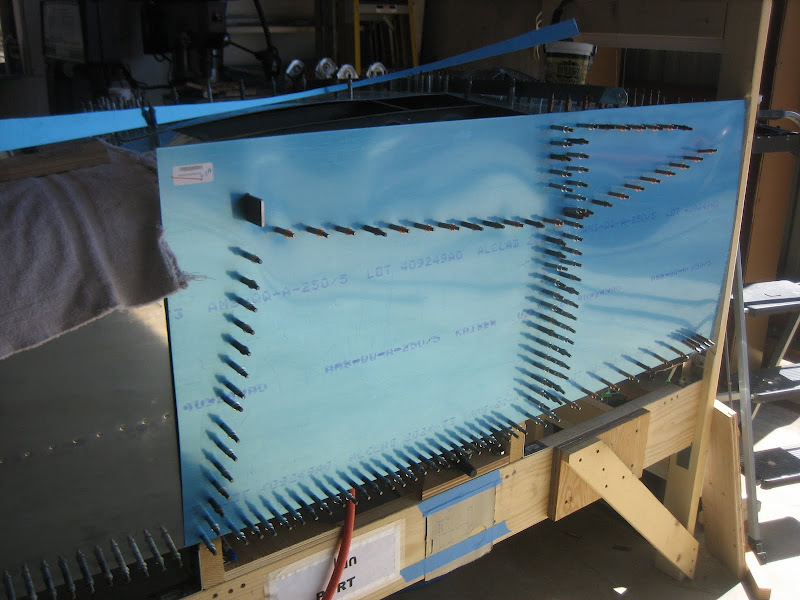

Rectangular forward side skin blank drilled in place:

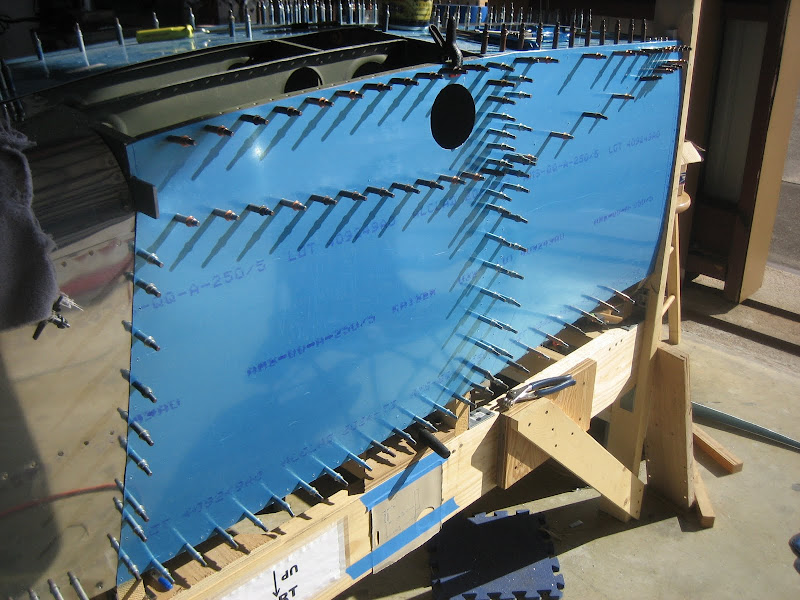

Side Skin trimmed, cut, and clecoed in place:

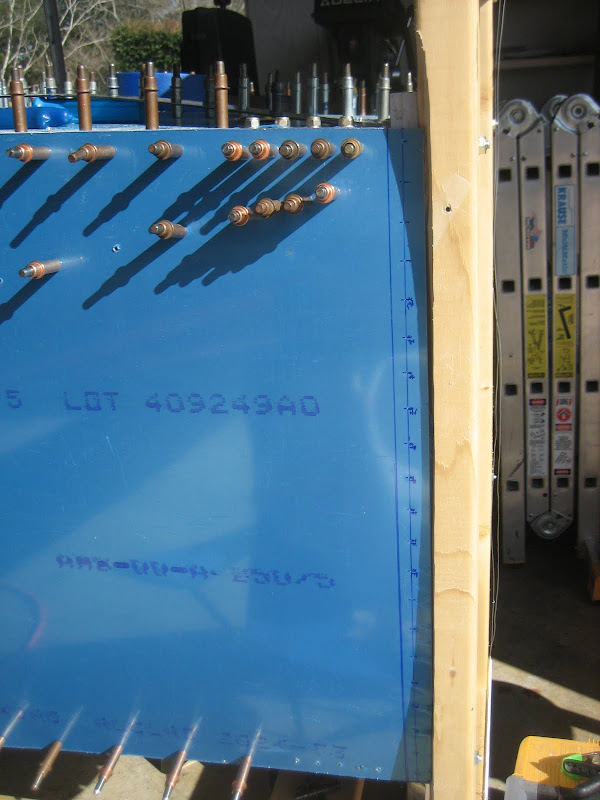

Firewall support on jig carved to allow skin to fit close:

?Look Ma?, I got Skin!!?

Paul

1) As has been noted before, be very suspicious about the fit of the bulkheads. We had several that fit well, and a couple that fit poorly. Plan to adjust or re-flange as required. We didn?t feel they were all bad enough to re-flange, but some just don?t work well.

2) We decided to go with Randy Lervold?s suggestion to use -3 rivets at 1? spacing on the longerons instead of -4 at 2?. As randy pointed out, the -3 rivets are used on later RV?s, and the closer spacing will help the skins lay down better.

3) This is old news to anyone who has riveted a slow-build fuselage, but especially on the narrow -3, it was very easy to cleco on the first side and reach across the jig to buck those rivets before clecoing on the other side. This way, the Bucker only has to live inside the cave for half the time.

4) After riveting the skins aft of the F-305, we fit the cockpit floor skins, followed by the forward bottom skin, and then did the side panels. This seemed pretty efficient, and we only had to disassemble things a couple of times. We fabricated the forward floor ribs (the triangular-shaped ones that also brace the firewall in the center) and drilled them to the forward floor. Since they help to define the shape of that floor skin, I felt it would give us a truer location for the outside and aft drill holes, and that seemed to work well.

5) When fitting the forward side skins, we measured and predrilled all the rivet holes in the skeleton first (stringers, longerons, and bulkheads), then back drilled through the skins, with one person putting backing the skin from the outside with a small piece of wood, then clecoing the holes. It probably took us an hour per side ? very fast.

6) We fit the side skins and drilled them to the skeleton before trimming them at all (except for cutting a rectangular hole for the rear spar carry-through. We removed the false main spar stubs, cockpit floor skins (because of the overhang) and all clecos that were in the way of the skin as we drilled. We first drilled it to the longeron between the F-303 and F-305. This pretty much fixed the skin in position, and we proceeded to drill out way up the bulkheads and along the stringers. The fit was excellent.

7) Locating the aft spar hole in the side skin was easier than I had thought. I was thinking that it would be a nightmare due to nothing being square, but since we worked with the side skins when they were still rectangular, it was a very simple measurement horizontally aft from the firewall and up (in the jig) from the longerons. Took a minute, and both sides located perfectly ? I am rarely that lucky!

8) After drilling the rectangular-shaped blank for the side skins and clecoing it in place, we marked it for trimming, removed it, and cut it to shape. Having traced the cut-out for the aileron pushrod hole before removing it, we cut that, then clecoed it back in place, did final trimming, and cut out the hole for the main spar using a Uni-bit to start a hole, then a nibbler to enlarge it, and finally an angle die-grinder with a sanding disc on it to make it to final size.

9) There is what we call ?the really ugly joint? right where the F-305 meets the stringer coming forward, the stringer coming aft (at the top of the seat rib), and the skin. It looked like it was going to be a real nightmare, thick and full of things that didn?t stack quite right ? but with the skin on, it is far better. I still haven?t figured out the rivets there, but I now at least believe there is a glimmer of hope it will work out. Building is like that ? you go from ?it?s impossible? to ?well, maybe? to ?that?s only half bad? to ?it?s strong, and no one will ever notice?? in the process of fabrication!

10) I didn?t see any drawing call-outs for a line of rivets along the bottom edge of the outside seat ribs (to hold it to the skin), so I drilled 2?-spaced holes for -4 rivets. They?ll be hidden by the wing roots anyway. It really helped the final fit!

11) I had to carve away some wood off the outside of the firewall uprights on the jig to allow the skin to lie against the firewall flange. Sawdust mixed with aluminum dust ? going to have to clean up the shop!

12) Since the aft side skins were already drilled and clecoed to the F-305 bulkhead flange, it was easy to match-drill this line of holes to the forward side skin. I then laid out the second column of rivets for that overlap joint based on that row. Worked really slick.

13) Next up is staring at it awhile to see where we need a few more rivets, fitting the exhaust tunnel sides, then disassembly for de-burring, dimpling, countersinking, etc. in prep for riveting. I hate taking things apart once it looks like something ? but that?s the name of the game!

A few pictures :

Rectangular forward side skin blank drilled in place:

Side Skin trimmed, cut, and clecoed in place:

Firewall support on jig carved to allow skin to fit close:

?Look Ma?, I got Skin!!?

Paul