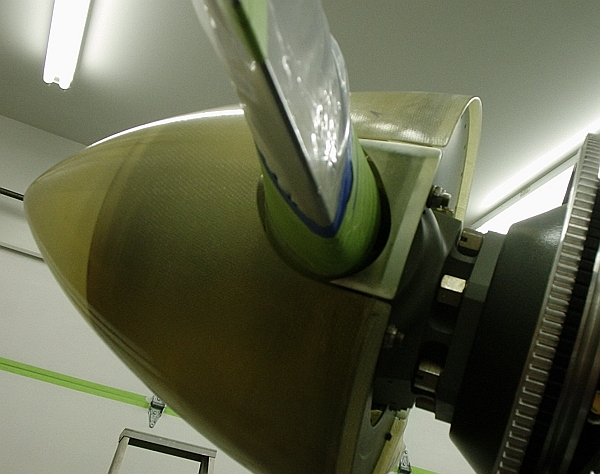

The mold shells mean the new gap plates will match the curvature of the spinner, precisely match the shape of the opening, and will have integral flanges.

Get out the cutting board and prepare 8 identical pieces of 9 oz fabric. These were 5 x 6, but you may need a different size depending on your cutout. Stack four each on two sections of plastic sheet. Cut a plastic cover sheet too. Mix about 50 grams of epoxy. Pour a little of it in another cup and set it aside. Pour the rest on the two fabric stacks:

Ignore the small stacks in the above picture; more flange material for my installation.

While the resin is soaking the stacks, grab the other cup you previously set aside and mix in some micro, plus just a pinch of flox. Make it about like peanut butter. Wipe in a small fillet around the edge of the prop cutout:

Fabric can't fill this joggle; if you try you'll wind up with a trapped air bubble. The fillet material allows the fabric to smoothly lay over the joggle without trapped air, and it will precisely define the cutout edge on the finished part.

Go back to the fabric patches, add resin to any dry spots, and lay a plastic sheet on top of the pile. Roll or squeegee to fully saturate the fabric and remove excess resin, plus any trapped air:

Cut right through the plastic to trim the saturated fabric stack to the desired final size. Carefully peel the plastic off one side, and place the stack:

In my case I had to trim around the flanges, but you won't. Smooth it down, starting from the center and working outward to remove any trapped air bubbles. Now carefully peel the plastic sheet off the top. Use a cheap chip brush to stipple down any disturbed fabric and remove any remaining air.

Add a flange to the wet fill plate by clamping something slick to the existing spinner flanges, wiping in a small flox filet, and adding layups for the necessary flange thickness.

More tomorrow.