I posted about a trip we made where my wife and I froze but didnt want to get off topic on the weekend thread. We were so cold we had to land to warm up. My carbon monoxide detector said it was 21 degrees inside. We warmed up at the airport, found a hole in the clouds and were in sunshine the rest of the trip warming up to about 60 in the cockpit. Thanks for the responses. I am open to suggestions!

I have an old Vans made exhaust with the loaf of bread heat muff. It does not do the trick.

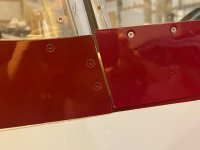

I spoke to Larry V and Clint about it a couple years ago and Clint said he could modify my exhaust so I could add another heat muff. I tried to contact him but no luck. The construction picture shows what I have.

Both my wife and I had heated vests on, she had a blanket and scarf. Next time we will wear ski outfits.

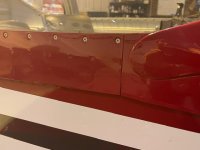

Sealing the canopy. On my tip up, I increased the width of the skirt to overlap the joint to match up with the other panel lines. I also have weatherstripping on the inside. I taped over the air vents on the outside so no air could leak in. My daughter is making me the aileron boots and Im sure that will help. Im thinking of adding carpet under the seats and on the floor around the seats to help both with sound and heat. I have carpet in the baggage area but nothing on the back bulkhead. Im sure air leaks around and under the bulkhead.

I had Abby install seat heaters when she did my seats but had not wired them up. I have been doing that the past 2 days. Im thinking of getting a 12v portable heater to see if that helps.

Question - has anyone put fiberglass or another insulation under the floor panels? Any other ideas on how to get more heat? Im ready to get a new exhaust system with 2 muffs if needed.

Any other ideas?

My wife and I had a nice trip and I dont want to lose her as a passenger.

I have an old Vans made exhaust with the loaf of bread heat muff. It does not do the trick.

I spoke to Larry V and Clint about it a couple years ago and Clint said he could modify my exhaust so I could add another heat muff. I tried to contact him but no luck. The construction picture shows what I have.

Both my wife and I had heated vests on, she had a blanket and scarf. Next time we will wear ski outfits.

Sealing the canopy. On my tip up, I increased the width of the skirt to overlap the joint to match up with the other panel lines. I also have weatherstripping on the inside. I taped over the air vents on the outside so no air could leak in. My daughter is making me the aileron boots and Im sure that will help. Im thinking of adding carpet under the seats and on the floor around the seats to help both with sound and heat. I have carpet in the baggage area but nothing on the back bulkhead. Im sure air leaks around and under the bulkhead.

I had Abby install seat heaters when she did my seats but had not wired them up. I have been doing that the past 2 days. Im thinking of getting a 12v portable heater to see if that helps.

Question - has anyone put fiberglass or another insulation under the floor panels? Any other ideas on how to get more heat? Im ready to get a new exhaust system with 2 muffs if needed.

Any other ideas?

My wife and I had a nice trip and I dont want to lose her as a passenger.