Wanted to get the forum's opinion on the following...I've sent this to Vans technical support for their opinion as well, but in the meantime thought I would ask here also.

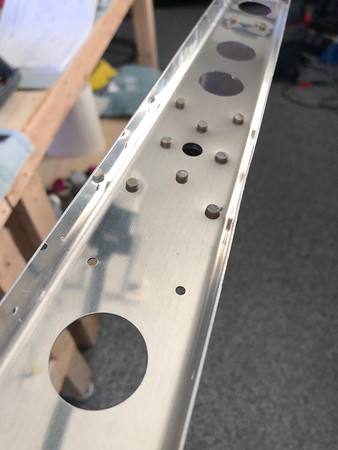

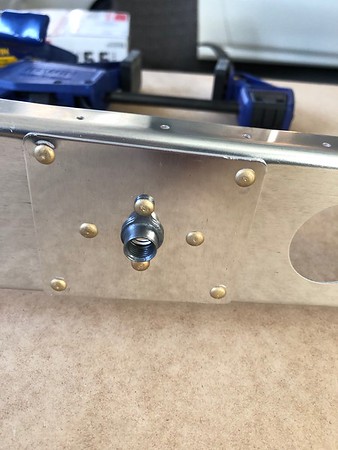

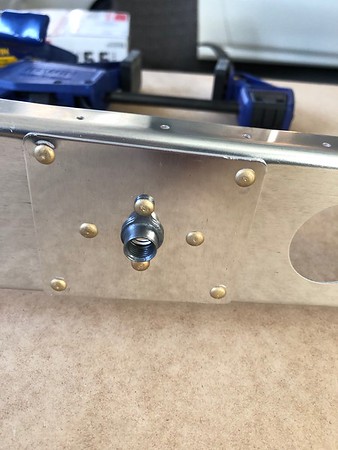

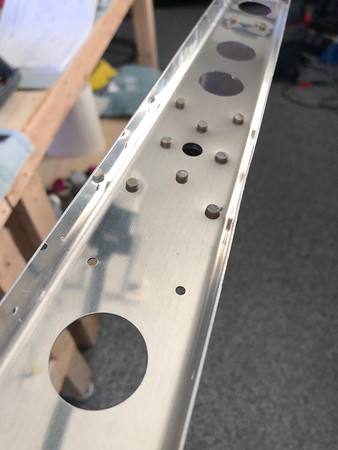

I recently completed riveting the Rudder Spar Reinforcement Plates onto the rudder spar for my RV-14A. I riveted them to the spar with the shop head on the spar side of the spar, when in retrospect I probably should have riveted them with the shop head on the plate side of the spar since that is the thicker material. The plans didn?t specify, so I didn?t think it would matter one way or the other.

Because the spar is thinner, there was some slight deformations/indentations made in the spar where the rivet shop heads were formed with the squeezer. Also, there is a slight gap between the reinforcement plates and the spar itself in a couple of areas. The rivets themselves look like their set fine.

My question is?.is this acceptable? If not, is it repairable? Or am I looking at buying a new rudder spar? Pictures are below.

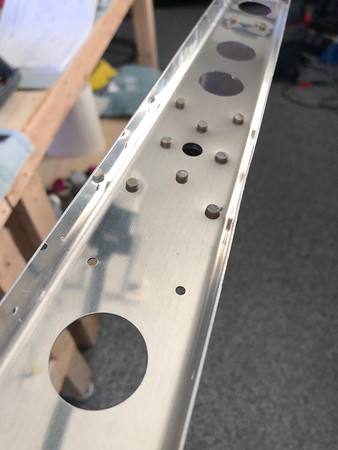

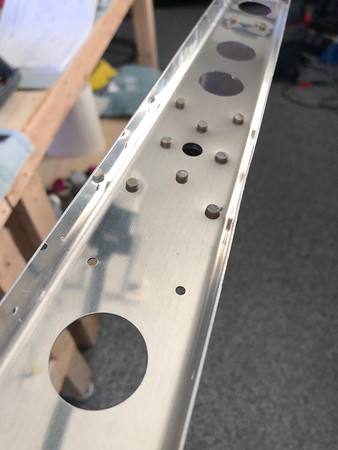

I recently completed riveting the Rudder Spar Reinforcement Plates onto the rudder spar for my RV-14A. I riveted them to the spar with the shop head on the spar side of the spar, when in retrospect I probably should have riveted them with the shop head on the plate side of the spar since that is the thicker material. The plans didn?t specify, so I didn?t think it would matter one way or the other.

Because the spar is thinner, there was some slight deformations/indentations made in the spar where the rivet shop heads were formed with the squeezer. Also, there is a slight gap between the reinforcement plates and the spar itself in a couple of areas. The rivets themselves look like their set fine.

My question is?.is this acceptable? If not, is it repairable? Or am I looking at buying a new rudder spar? Pictures are below.