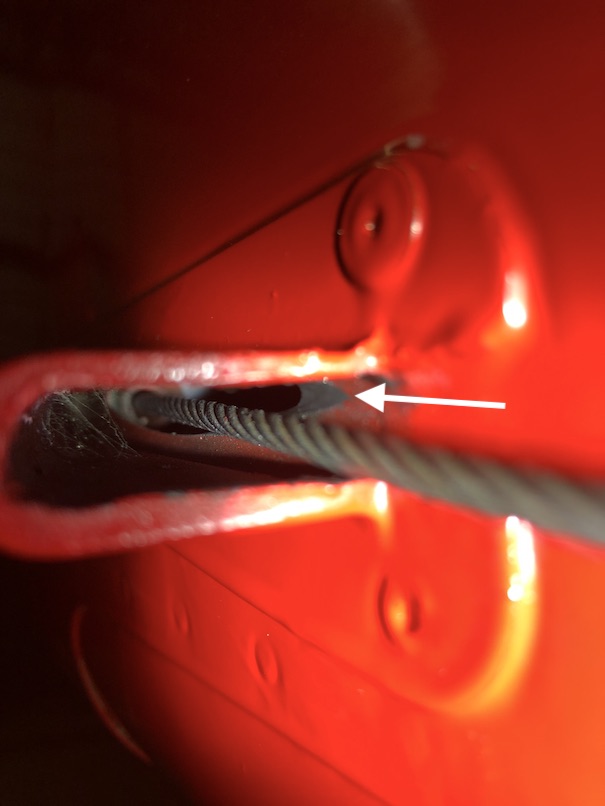

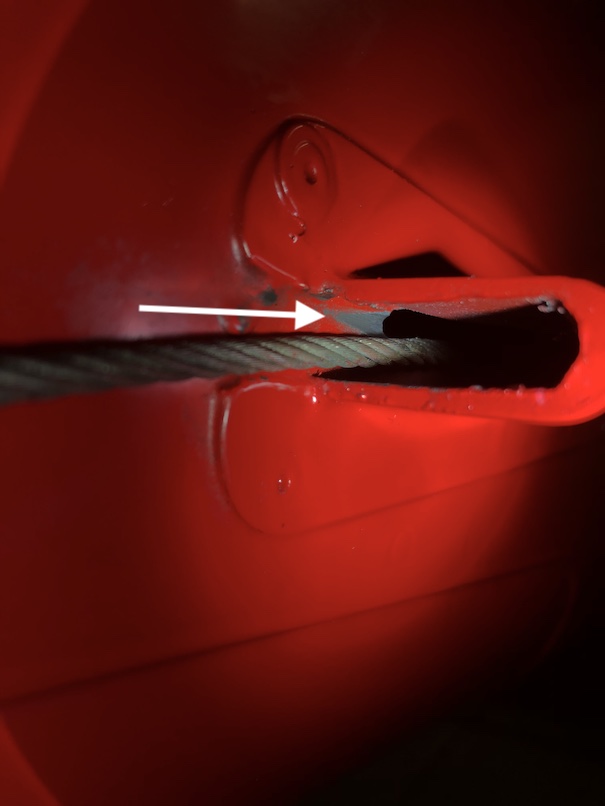

After watching Vic Syracuse's webinar on eaa.org the other day I did an extra detailed preflight to catch any of the common maintenance items talked about. Didn't find any loose nuts but I found the rudder cables chafing on fuse skin where they exit under the cable fairings at the tail. I didn't take a picture but I can tell you that it's been happening since the airplane was built 600 hours ago.

The cables look okay other than the coating of aluminum built up over time. The fuse skin has worn down to sharp edge where the cable is chafing. There's no mention of this issue in any of the conditional checklists in the aircraft records.

Questions:

The cables look okay other than the coating of aluminum built up over time. The fuse skin has worn down to sharp edge where the cable is chafing. There's no mention of this issue in any of the conditional checklists in the aircraft records.

Questions:

- Is there an issue with galvanic corrosion with the buildup of aluminum, assuming the cable is stainless or galvanized?

- Should one worry about the stress point on fuselage skin? Repair or monitor?

- What fixes are folks employing to prevent chafing? I've seen a couple solutions in the picts below...

Last edited: