Hi all,

So, last week my vacuum pump failed and I took it as a hint that I should finally start my panel upgrade. The plan is to go from steam gauges to G3X. Now, I haven't built an airplane, and while I'm pretty comfortable with the electronics and wiring, metal work is fairly new to me. So I'd like to ask a few potentially dumb questions if you don't mind.

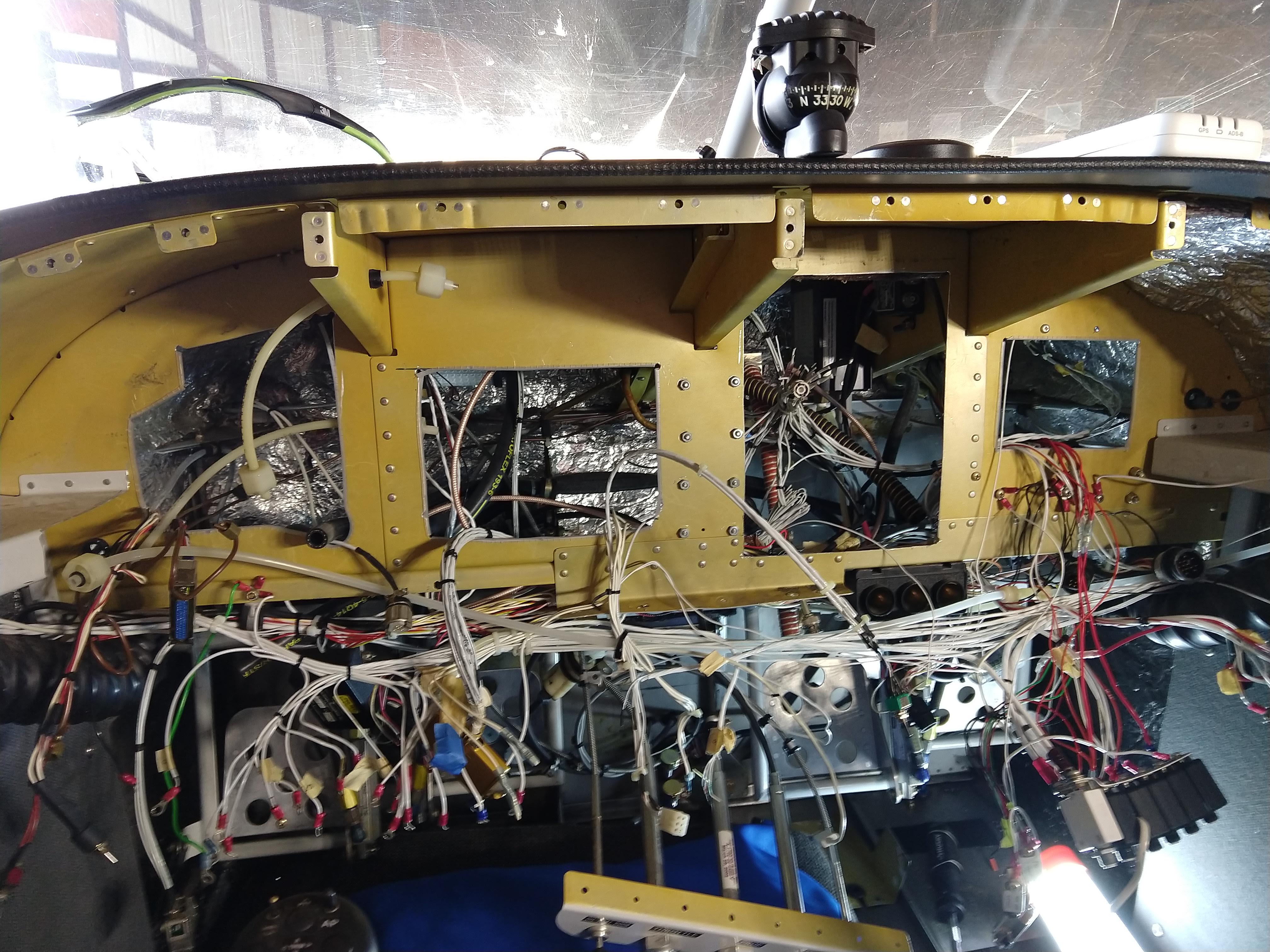

In looks like in the course of years the subpanel on my RV-7 (slider) endured some surgery:

I now need to patch at least some of these holes to mount G3X components onto. What would be my best course of action? My current plan is to make a patch out of a 0.040 sheet and rivet it with a combination of AD4 where I can squeeze them and cherry rivets where I can't (I'm not set up for riveting with a rivet gun). Would a single row of rivets be sufficient? Given how decimated the subpanel is, it's probably not very structural?

Also, F-712A-L was also cut for some reason without any reinforcement. Should I do something about it? Maybe add a angle stiffener or something?

Thanks for any advice!

So, last week my vacuum pump failed and I took it as a hint that I should finally start my panel upgrade. The plan is to go from steam gauges to G3X. Now, I haven't built an airplane, and while I'm pretty comfortable with the electronics and wiring, metal work is fairly new to me. So I'd like to ask a few potentially dumb questions if you don't mind.

In looks like in the course of years the subpanel on my RV-7 (slider) endured some surgery:

I now need to patch at least some of these holes to mount G3X components onto. What would be my best course of action? My current plan is to make a patch out of a 0.040 sheet and rivet it with a combination of AD4 where I can squeeze them and cherry rivets where I can't (I'm not set up for riveting with a rivet gun). Would a single row of rivets be sufficient? Given how decimated the subpanel is, it's probably not very structural?

Also, F-712A-L was also cut for some reason without any reinforcement. Should I do something about it? Maybe add a angle stiffener or something?

Thanks for any advice!