MartinPred

Well Known Member

After a two-year rebuild, the good news my Lycoming O-360-A1D is back to together on my RV-4, and started up just fine with no oil leaks. My tappet bodies had corroded, damaging the cam, and forcing me to do a complete rebuild, which I decided to do myself. I was only able to work a few hours a week, so it took me the last two years to complete.

I followed the Lycoming overhaul manual line by line, and had an A&P buddy ofmine looking over everything at key steps.

But the bad news is, I think I missed something. After two engine runs, with the oil bypass valvle cranked all the way in, I'm still getting very low oil pressure--no higher than 21 PSI at 1800 RPM. Maybe it's a bad guage, but I think it's something else.

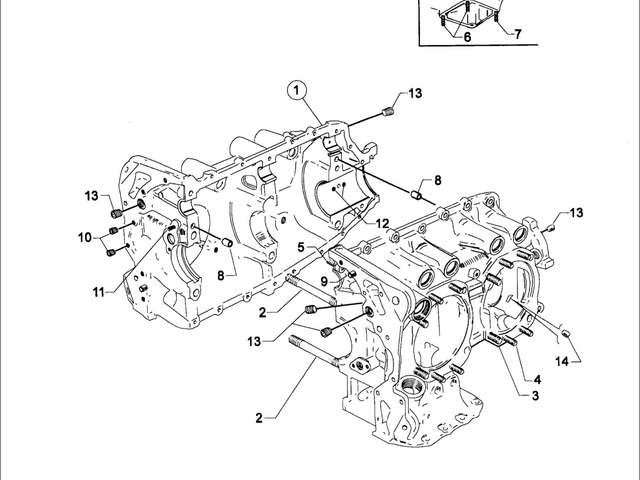

I went through all the photos I took during reassembly, and I think I forgot to install the galley plugs in the accessory case. The only photos I took of that area all show the plugs missing, and I don't remember putting them in.

So the question: does anyone know a technique to install those plugs without pulling the motor and removing the sump and accessory case? It looks like there might be enough clearnance through the mag holes to get them in there. But then how do you torque them, and is there a good way to make sure you don't accidently drop them into the sump?

After all this work, it would be a shame to still be weeks away from flying.

Thanks,

-Matt

N402BD

I followed the Lycoming overhaul manual line by line, and had an A&P buddy ofmine looking over everything at key steps.

But the bad news is, I think I missed something. After two engine runs, with the oil bypass valvle cranked all the way in, I'm still getting very low oil pressure--no higher than 21 PSI at 1800 RPM. Maybe it's a bad guage, but I think it's something else.

I went through all the photos I took during reassembly, and I think I forgot to install the galley plugs in the accessory case. The only photos I took of that area all show the plugs missing, and I don't remember putting them in.

So the question: does anyone know a technique to install those plugs without pulling the motor and removing the sump and accessory case? It looks like there might be enough clearnance through the mag holes to get them in there. But then how do you torque them, and is there a good way to make sure you don't accidently drop them into the sump?

After all this work, it would be a shame to still be weeks away from flying.

Thanks,

-Matt

N402BD