WingnutWick

Well Known Member

So after the new RV-6As mixture bound and bent for the second time I decided to take it upon myself to replace the quadrant style cables that were wrapping around the carb to make the direction of travel correct and go with the standard RV-6 setup. I ordered the RV-6 throttle and mixture cables from vans and the RV-6 O-320 bracket.

Woe #1: the bracket did not fit correctly and I had to cut and bend it to meet it from pressing against the oil pan. Then I had to dremel out a hole for the oil drain to go through. Not pretty but figured it?d due the trick. I chalked the bracket not fitting great due to the motor being an H2AD and kind of an odd ball engine, but I don?t really know.

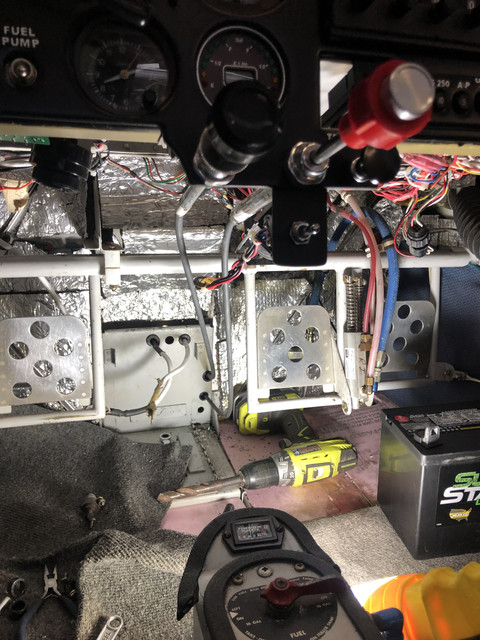

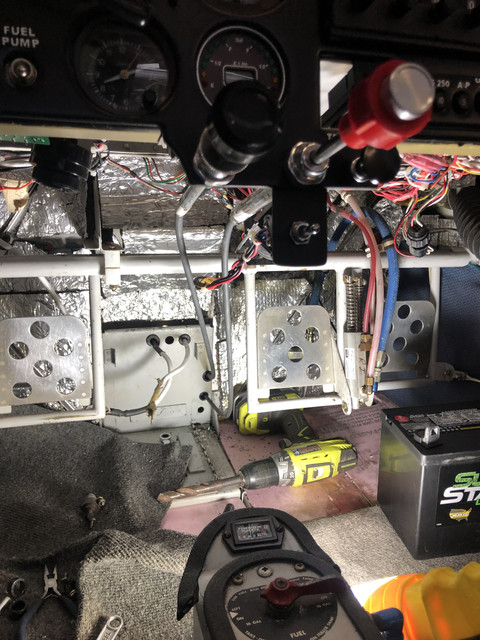

Woe #2: Drilling the holes. With everything mounted on I couldn?t use a template so I had to eyeball it. The battery is in the inside of the cockpit centered between the rudders and in front of where they say to put the mixture control so I elected to have the mixture come out to the right of the battery below the throttle thinking that bend wouldn?t be enough to hamper the movement of the control. A royal PITA working under the dash like that with my 6ft4 frame. Plus there is this shield that is behind the battery that I had to work through.

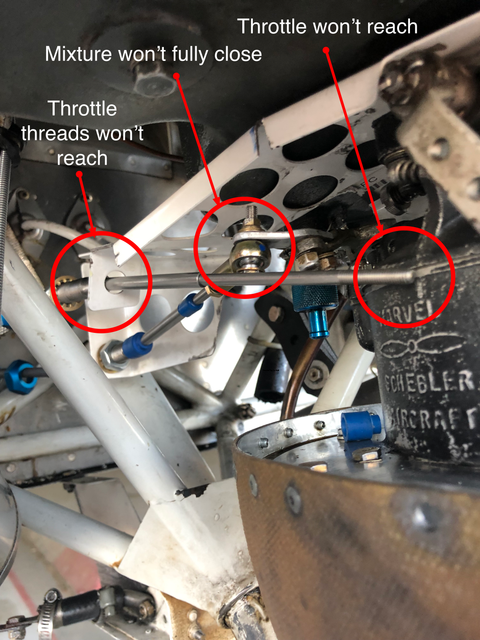

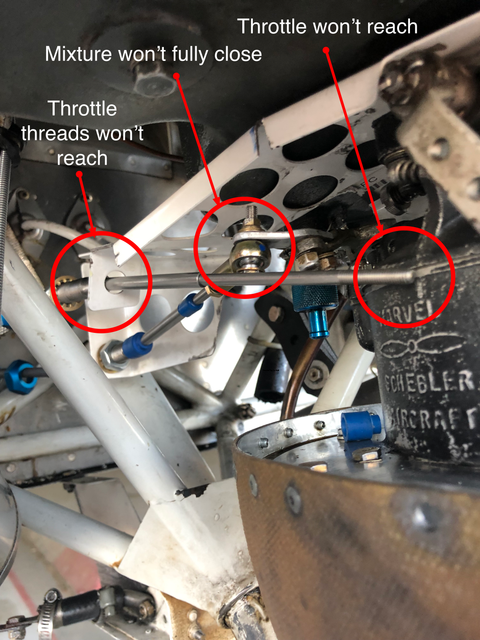

Woe #3: Finally got the cables routed and through the firewall. And all the hardware put in only to find that the throttle cable doesn?t reach the bracket hole, let alone the throttle arm to allow for full throttle. This is bizarre because it?s pretty much B-lining straight from the dash to the firewall and to the carb. Furthermore the mixture doesn?t want to travel all the way out (lean). Not sure if that is binding due to the small curve but I?ve seen more aggressive curves on other?s planes work.

Before I went putting more holes in the firewall I want to check in and see if anyone know what the heck is going on here!? Inputs, insights, suggestions always very much appreciated!!

Thank you all!

Charles

Woe #1: the bracket did not fit correctly and I had to cut and bend it to meet it from pressing against the oil pan. Then I had to dremel out a hole for the oil drain to go through. Not pretty but figured it?d due the trick. I chalked the bracket not fitting great due to the motor being an H2AD and kind of an odd ball engine, but I don?t really know.

Woe #2: Drilling the holes. With everything mounted on I couldn?t use a template so I had to eyeball it. The battery is in the inside of the cockpit centered between the rudders and in front of where they say to put the mixture control so I elected to have the mixture come out to the right of the battery below the throttle thinking that bend wouldn?t be enough to hamper the movement of the control. A royal PITA working under the dash like that with my 6ft4 frame. Plus there is this shield that is behind the battery that I had to work through.

Woe #3: Finally got the cables routed and through the firewall. And all the hardware put in only to find that the throttle cable doesn?t reach the bracket hole, let alone the throttle arm to allow for full throttle. This is bizarre because it?s pretty much B-lining straight from the dash to the firewall and to the carb. Furthermore the mixture doesn?t want to travel all the way out (lean). Not sure if that is binding due to the small curve but I?ve seen more aggressive curves on other?s planes work.

Before I went putting more holes in the firewall I want to check in and see if anyone know what the heck is going on here!? Inputs, insights, suggestions always very much appreciated!!

Thank you all!

Charles