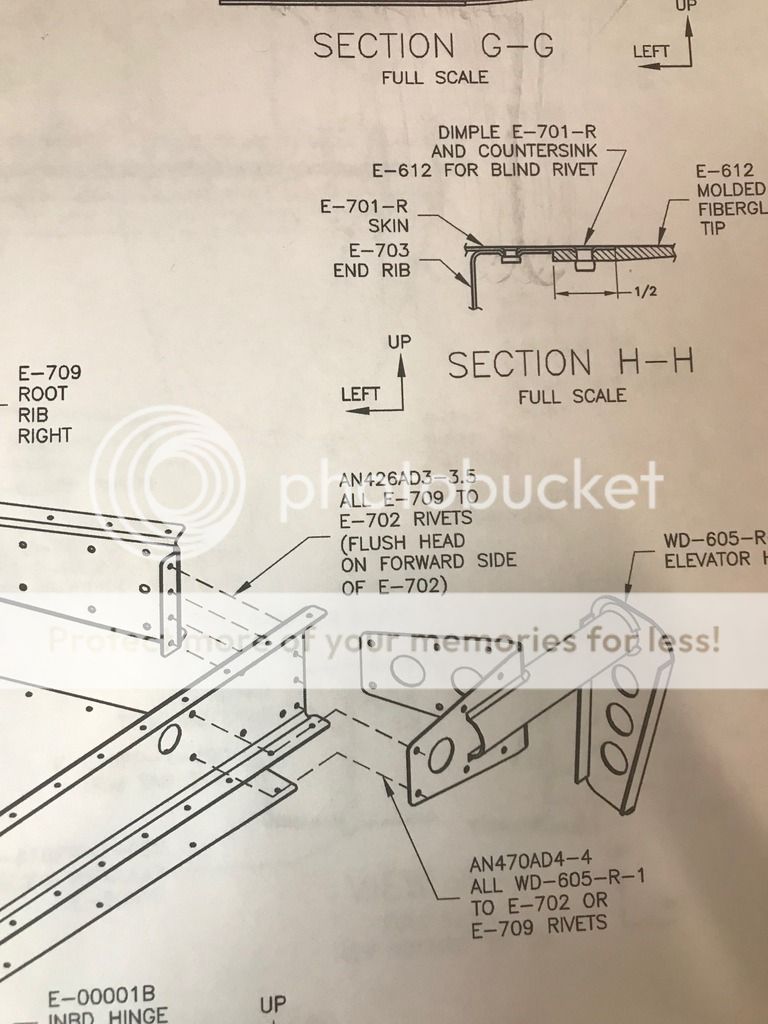

This is a case in example where you are over thinking this. I remember this. In situations like this, ALWAYS recall the option to simply grab your hand debur tool, change out its debur bit with the #40 or #30 countersink (whichever matches the hole) toolling bit, then hand countersink using finesse and care. And move on.

Obviously return the deburr tooling bit back into your hand deburr tool.

Yes, you can dimple these here. That advice applies. It's just overkill. But yes, dimpling is always better. Just not needed in this instance.

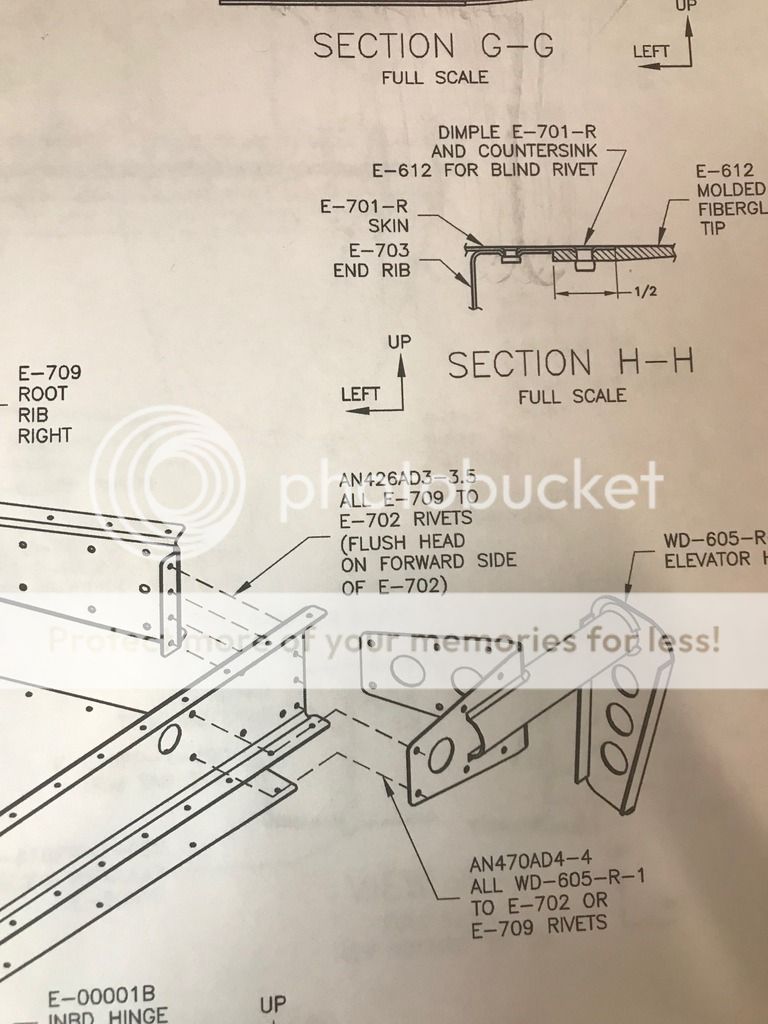

Good time to point out an important SIDE NOTE, for in your future. I learned the hard way. Please trust me; just make a sticky note and do not forget this...When you get to you fuel tanks....(I know, that is down the road), but no one does a good job of conveying this and Vans won't tell you. There is a row of rivets on the rear portion of the fuel tanks (top and bottom) for the Skin to the Rear Baffle. Vans says to countersink these. Absolutely do not countersink these. I did. and these look like horse $#!T. Everything with tanks came out perfect as to plan, but one of the last final steps...these skin to baffle rivets...they ruined this otherwise seamless process. Absolutely no need for the mentioned clearance need that vans state in the drawing. That is BS. Dimple these! Please! You will get a many times over better finish of your tanks. Frustrated no one shared this tip to me ahead of time, otherwise my tanks would have finished out perfect.

Anyways. like I learned....guard yourself from over thinking. Use the MIL spec for your quality guidelines. If the rivet meets MIL spec, move on.