HeliCooper

Well Known Member

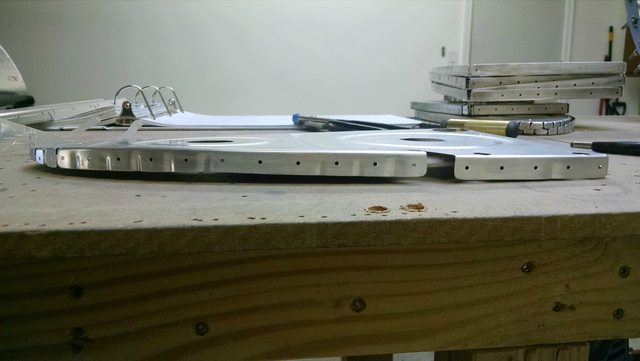

I am running into this while trying to flute the nose ribs. The first two pictures show what the rib looks like after fluting without an pressure. You can see there is a pressure forming a twist in the rib.

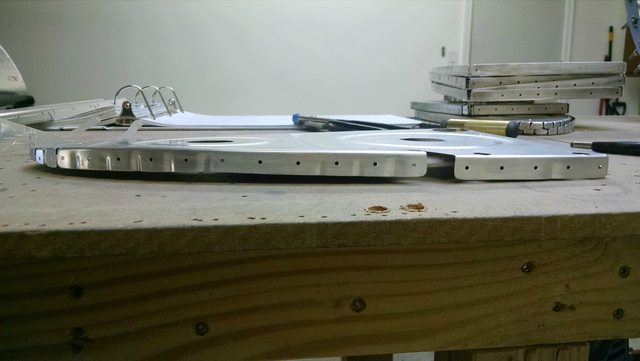

If I hold pressure on the rib you can see that the flange itself is straight on both sides. Pressure is very light. Guessing just a pound or so.

Also of note in this picture you see the gap under my thumb between the flange and the table. This gap is present on all the ribs before fluting and as far as I can tell is not correctable.

Should I just leave them fluted like this or do I need to figure out how to get that load off the rib?

If I hold pressure on the rib you can see that the flange itself is straight on both sides. Pressure is very light. Guessing just a pound or so.

Also of note in this picture you see the gap under my thumb between the flange and the table. This gap is present on all the ribs before fluting and as far as I can tell is not correctable.

Should I just leave them fluted like this or do I need to figure out how to get that load off the rib?