I'm looking for recommendations for the oil cooler for an RV-8 I'm finishing the build on (IO-360 angle valve with C/S prop, stock comp, and electronic ignition). Has anyone has mounted an 11 row cooler and if so how much effort did it take to fit it in the -8 cowling?? For those who have experience with the 8 row recirculating oil cooler in hot climates, how have your oil temps been in climbs. I'm thinking the 8 row recirculating cooler is probably adequate, and fitting the 11 row may be problematic. Thank you in advance!!!

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RV-8 oil cooler recommendations

- Thread starter N670SB

- Start date

Onewinglo

Active Member

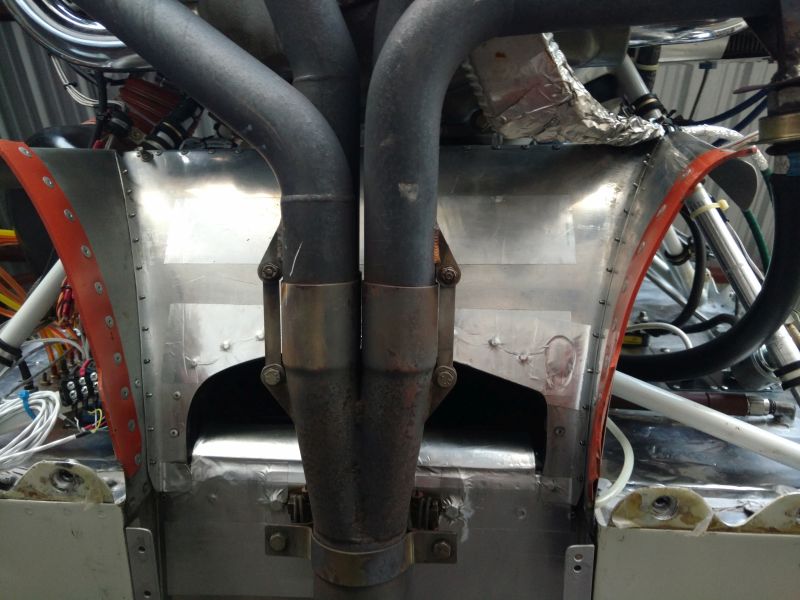

It Can Be Done...

We mounted an oversized oil cooler but attached it to the engine mount. We later added a butterfly valve to throttle the cooling flow in order to get oil temp up to 180*. I don't remember the brand and row number but I'll look. Parallel valve Superior O360.

https://photos.app.goo.gl/bjZsuhdu9KM8VXtm8

https://photos.app.goo.gl/1Y8gCNVr2vuNhUad6

Our oil cooler is a Dual Pass, 8 row cooler recommended by Pacific Oil Cooler. It's a bit bigger than we needed. We have a fixed pitch prop.

We mounted an oversized oil cooler but attached it to the engine mount. We later added a butterfly valve to throttle the cooling flow in order to get oil temp up to 180*. I don't remember the brand and row number but I'll look. Parallel valve Superior O360.

https://photos.app.goo.gl/bjZsuhdu9KM8VXtm8

https://photos.app.goo.gl/1Y8gCNVr2vuNhUad6

Our oil cooler is a Dual Pass, 8 row cooler recommended by Pacific Oil Cooler. It's a bit bigger than we needed. We have a fixed pitch prop.

Last edited:

I started with a SW/Meggit 10599 and later switched to a 10611. I've never counted rows. Both were remote mounted, which was not an issue. I've seen multiple approaches to mounting.

There are a lot of opinions about acceptable oil temperature. Mine is that I never want to see 210F, but will accept short excursions to around 205 in a long climb. Likewise I want oil temp within the same parameters given a taxi of any length, or multiple laps around the Ripon approach at 90 knots.

Both coolers were full ducted. With the 10599, I played with ducting cold air to the cooler, bypassing the hot fins in the upper plenum. The supply temperature difference was 16F. It worked, but a larger cooler worked better overall.

Exit ducting runs to a converging bell in the cowl exit. Pressure at the end of oil cooler duct is about 1.5" H2O above freestream static in cruise. Typical lower cowl pressure for RV's is 1.5" to 2" at cruise, with some examples outside those points. My lower cowl pressure in cruise is more like 6", as I run a very small cowl exit. The cooler would not have enough air pressure drop across it without the exit ducting.

http://www.vansairforce.com/community/showpost.php?p=1057297&postcount=197

IO-360 angle valve/CS with standard cowl? Remote 10611 or similar. Parallel valve engines without squirters need less. Fixed pitch needs less.

There are a lot of opinions about acceptable oil temperature. Mine is that I never want to see 210F, but will accept short excursions to around 205 in a long climb. Likewise I want oil temp within the same parameters given a taxi of any length, or multiple laps around the Ripon approach at 90 knots.

Both coolers were full ducted. With the 10599, I played with ducting cold air to the cooler, bypassing the hot fins in the upper plenum. The supply temperature difference was 16F. It worked, but a larger cooler worked better overall.

Exit ducting runs to a converging bell in the cowl exit. Pressure at the end of oil cooler duct is about 1.5" H2O above freestream static in cruise. Typical lower cowl pressure for RV's is 1.5" to 2" at cruise, with some examples outside those points. My lower cowl pressure in cruise is more like 6", as I run a very small cowl exit. The cooler would not have enough air pressure drop across it without the exit ducting.

http://www.vansairforce.com/community/showpost.php?p=1057297&postcount=197

IO-360 angle valve/CS with standard cowl? Remote 10611 or similar. Parallel valve engines without squirters need less. Fixed pitch needs less.

Last edited:

I started with a SW/Meggit 10599 and later switched to a 10611. I've never counted rows. Both were remote mounted, which was not an issue. I've seen multiple approaches to mounting.

There are a lot of opinions about acceptable oil temperature. Mine is that I never want to see 210F, but will accept short excursions to around 205 in a long climb. Likewise I want oil temp within the same parameters given a taxi of any length, or multiple laps around the Ripon approach at 90 knots.

Both coolers were full ducted. With the 10599, I played with ducting cold air to the cooler, bypassing the hot fins in the upper plenum. The supply temperature difference was 16F. It worked, but a larger cooler worked better overall.

Exit ducting runs to a converging bell in the cowl exit. Pressure at the end of oil cooler duct is about 1.5" H2O above freestream static in cruise. Typical lower cowl pressure for RV's is 1.5" to 2" at cruise, with some examples outside those points. My lower cowl pressure in cruise is more like 6", as I run a very small cowl exit. The cooler would not have enough air pressure drop across it without the exit ducting.

http://www.vansairforce.com/community/showpost.php?p=1057297&postcount=197

IO-360 angle valve/CS with standard cowl? Remote 10611 or similar. Parallel valve engines without squirters need less. Fixed pitch needs less.

Dan,

Do you have some photos of the current inlet and exit duct installed in the airplane?

elev666

Well Known Member

Butterfly Valve

We mounted an oversized oil cooler but attached it to the engine mount. We later added a butterfly valve to throttle the cooling flow in order to get oil temp up to 180*. I don't remember the brand and row number but I'll look. Parallel valve Superior O360.

https://photos.app.goo.gl/bjZsuhdu9KM8VXtm8

https://photos.app.goo.gl/1Y8gCNVr2vuNhUad6

JP , would you happen to remember were you sourced the butterfly valve you used , I?m using a FW mounted 13 row and there will be days I need to close off cooling air flow here , yours looks nice and light and will save me reinventing one here !

We mounted an oversized oil cooler but attached it to the engine mount. We later added a butterfly valve to throttle the cooling flow in order to get oil temp up to 180*. I don't remember the brand and row number but I'll look. Parallel valve Superior O360.

https://photos.app.goo.gl/bjZsuhdu9KM8VXtm8

https://photos.app.goo.gl/1Y8gCNVr2vuNhUad6

JP , would you happen to remember were you sourced the butterfly valve you used , I?m using a FW mounted 13 row and there will be days I need to close off cooling air flow here , yours looks nice and light and will save me reinventing one here !

I started with a SW/Meggit 10599 and later switched to a 10611. I've never counted rows. snipped

The 10599's core has 8 rows.

The 10611's core has 11 rows

Both cores are 6" wide

Charlie

Danny King

Well Known Member

Quote: I started with a SW/Meggit 10599 and later switched to a 10611. I've never counted rows. Both were remote mounted, which was not an issue. I've seen multiple approaches to mounting.

DH

----------------------------------------------------------

Dan,

I am currently using the 10599 on my I0360A1B6 and cruise around 200F-205F. I know that is within limits, but would love to cruise closer to 190F. Would swapping my 10599 for a 10611 accomplish that? Will the 10611 mount in the foot print of the 10599? My 10599 is mounted behind #4 on the aft baffle.

Thanks,

Danny

DH

----------------------------------------------------------

Dan,

I am currently using the 10599 on my I0360A1B6 and cruise around 200F-205F. I know that is within limits, but would love to cruise closer to 190F. Would swapping my 10599 for a 10611 accomplish that? Will the 10611 mount in the foot print of the 10599? My 10599 is mounted behind #4 on the aft baffle.

Thanks,

Danny

scsmith

Well Known Member

Perhaps a moderator could move this thread out of the classifieds.

It should be noted that parallel valve and angle valve engines put very different heat loads into the oil. So recommendations for the OP from folks with parallel valve engines are not very meaningful.

With the angle valve engine, you want the biggest cooler you can get.

Mount it on the firewall with a low-resistance supply duct from the upper plenum, and include a butterfly valve to adjust flow for winter.

For a standard lower cowl exit, just dumping the cooler flow into the lower plenum will work fine. For reduced-area exits, it may be required to duct the cooler exit down and out the cowl exit as Dan described.

It should be noted that parallel valve and angle valve engines put very different heat loads into the oil. So recommendations for the OP from folks with parallel valve engines are not very meaningful.

With the angle valve engine, you want the biggest cooler you can get.

Mount it on the firewall with a low-resistance supply duct from the upper plenum, and include a butterfly valve to adjust flow for winter.

For a standard lower cowl exit, just dumping the cooler flow into the lower plenum will work fine. For reduced-area exits, it may be required to duct the cooler exit down and out the cowl exit as Dan described.

rvisnext

Active Member

13 row

Showplanes.com makes what I believe is the best solution without having to put the bigger oil cooler on the firewall. This is what I use with my angle valve 390, check it out on their website.

I'm looking for recommendations for the oil cooler for an RV-8 I'm finishing the build on (IO-360 angle valve with C/S prop, stock comp, and electronic ignition). Has anyone has mounted an 11 row cooler and if so how much effort did it take to fit it in the -8 cowling?? For those who have experience with the 8 row recirculating oil cooler in hot climates, how have your oil temps been in climbs. I'm thinking the 8 row recirculating cooler is probably adequate, and fitting the 11 row may be problematic. Thank you in advance!!!

Showplanes.com makes what I believe is the best solution without having to put the bigger oil cooler on the firewall. This is what I use with my angle valve 390, check it out on their website.

Onewinglo

Active Member

JP , would you happen to remember were you sourced the butterfly valve you used , I’m using a FW mounted 13 row and there will be days I need to close off cooling air flow here , yours looks nice and light and will save me reinventing one here !

Aircraft Spruce 3". The flange on the baffle came from Spruce also.

https://www.aircraftspruce.com/catalog/elpages/tcwcvservobv.php?clickkey=7368

A better view.

https://photos.app.goo.gl/d9FPhN24KVj4NZgz6

Last edited:

scsmith

Well Known Member

JP , would you happen to remember were you sourced the butterfly valve you used , I?m using a FW mounted 13 row and there will be days I need to close off cooling air flow here , yours looks nice and light and will save me reinventing one here !

I made my own 3.5" butterfly valve that mounted to the rear baffle and then attached a 3.5" scat tube to run to the cooler. I am now in the process of increasing to 4" scat and a 4" butterfly valve -- I think the 3.5" is a little too small for the large oil cooler for the angle valve engine.

I am currently using the 10599 on my I0360A1B6 and cruise around 200F-205F. I know that is within limits, but would love to cruise closer to 190F. Would swapping my 10599 for a 10611 accomplish that?

Probably, depending on upper and lower cowl pressure. I can tell you how to measure it if you wish to have assurance before doing the swap.

I have some cowl pressures for RV-8's. I'll look at the numbers. Remind me if I forget.

Will the 10611 mount in the foot print of the 10599? My 10599 is mounted behind #4 on the aft baffle.

No, it is physically larger, and will probably need to be remote mounted.

For Dan: For your converging oil cooler exit duct, what is the ratio of the duct exit area at the bottom of the cowl to the area at the exit of the cooler?

It does not extend all the way to the freestream, but rather to the top of a converging exit bell exhausting all the cowl air. Oil cooler mass flow meets the majority mass flow at a right angle, more or less, so I didn't want significant velocity. So, if the duct exit is smaller than the cooler face area, it is not by much. The area was set by the available space between engine mount tubes. I do not know the exact area.

Rallylancer122

Well Known Member

I just redid the oil cooler install in my Dad's RV8. IO390, Sam James cowl, and it had an 11 row Niagra on the left side that just wasn't cutting it. I was regularly seeing temps in the 210-220 range, and that was babying the engine.

So I bought an airflow-systems 13 row cooler and installed it on the right side. Basically I copied the showplanes installation. I would have just bought theirs but I have non-standard baffling so I built my own. In hindsight I probably should have just bought the showplanes kit and modified it. I looked at some more exotic coolers, but the 2006x appears to be a form/fit replacement for a 13 row Harrison which is pretty common. So if I'm ever somewhere and it fails odds are I can get a replacement quickly to get me home.

So far I'm quite happy with the results. Temps are consistently in the 180's, however our ambients in Wisconsin are cool right now so we'll see how it handles summer.

DEM

So I bought an airflow-systems 13 row cooler and installed it on the right side. Basically I copied the showplanes installation. I would have just bought theirs but I have non-standard baffling so I built my own. In hindsight I probably should have just bought the showplanes kit and modified it. I looked at some more exotic coolers, but the 2006x appears to be a form/fit replacement for a 13 row Harrison which is pretty common. So if I'm ever somewhere and it fails odds are I can get a replacement quickly to get me home.

So far I'm quite happy with the results. Temps are consistently in the 180's, however our ambients in Wisconsin are cool right now so we'll see how it handles summer.

DEM

Examples of each Style please

Jerry could you please provide links to examples of each of the two styles of oil cooler you have spoken about? Would I surmise correctly to think that the old Harrison is an example of one style and that is Stewart Warner would be an example of the other?

Charlie

Another consideration for oil cooler size is type ,drawn cup vs bar and plate, the bar and plate will typically be more efficient for heat dissipation due to fin design and area. I think before deciding on size alone the type of cooler should be considered.

Jerry could you please provide links to examples of each of the two styles of oil cooler you have spoken about? Would I surmise correctly to think that the old Harrison is an example of one style and that is Stewart Warner would be an example of the other?

Charlie

fl-mike

Well Known Member

https://www.kitplanes.com/oil-cooler-101/

shows the difference in the two types.

I also think one of the magazines had an article in the current issue, but I can't find my copy.

shows the difference in the two types.

I also think one of the magazines had an article in the current issue, but I can't find my copy.