Hello,

75 hours on this airplane since new. Everything worked perfectly for 75 hours then all of a sudden this started.

It's a dual lightspeed plasma III on an IO-360. At idle, and up to about 2000 RPM, the tach on the G3X reads accurately, then it starts to read 200-400 RPM too high by full power, as compared to an external tach (tru tach ii on the glareshield). Redline is 2700 and the tach will go to 3000+ if left alone. If I pull the circuit breaker for the left ignition the problem goes away and the tach is accurate, immediate return to normal RPM indications, only to return to abnormal indications if the circuit breaker is closed.

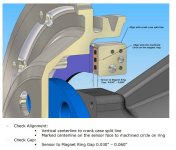

The system uses a magnet ring mounted to the flywheel and two mini sensors mounted behind the magnet ring, one sensor for each ignition. The G3X tach displays the higher of the two RPM indications, thus when the left system tach reading goes bonkers that's what shows up on the GDU-465/GEA-24 tach.

Additionally, I have encountered engine stumbling/roughness at full power during run ups if I allow the engine to run with the Tach showing 2900+ (while verifying it's not actually spinning that fast with an external tach). I assume this is the electronic ignition doing something to the timing/spark when it thinks the engine is overspeeding, even though it's not? The high RPM on the tach sets off a master warning on the G3X of course.

I've attached pictures of the mini sensors looking from above. Right sensor (functioning correctly) in first pic, left sensor (malfunctioning possibly?) in second pic. I know that's not exact but does the left-side sensor in the second picture look askew? I didn't install this, purchased a previously completed airplane. Could it be wiring or soemthing else? Could a misaligned sensor cause these problems? Could the sensor be contacting the flywheel at high RPM due to vibrations? I have a professional avionics shop looking at this, just trying to help get the bird back in the air.

Thanks.

75 hours on this airplane since new. Everything worked perfectly for 75 hours then all of a sudden this started.

It's a dual lightspeed plasma III on an IO-360. At idle, and up to about 2000 RPM, the tach on the G3X reads accurately, then it starts to read 200-400 RPM too high by full power, as compared to an external tach (tru tach ii on the glareshield). Redline is 2700 and the tach will go to 3000+ if left alone. If I pull the circuit breaker for the left ignition the problem goes away and the tach is accurate, immediate return to normal RPM indications, only to return to abnormal indications if the circuit breaker is closed.

The system uses a magnet ring mounted to the flywheel and two mini sensors mounted behind the magnet ring, one sensor for each ignition. The G3X tach displays the higher of the two RPM indications, thus when the left system tach reading goes bonkers that's what shows up on the GDU-465/GEA-24 tach.

Additionally, I have encountered engine stumbling/roughness at full power during run ups if I allow the engine to run with the Tach showing 2900+ (while verifying it's not actually spinning that fast with an external tach). I assume this is the electronic ignition doing something to the timing/spark when it thinks the engine is overspeeding, even though it's not? The high RPM on the tach sets off a master warning on the G3X of course.

I've attached pictures of the mini sensors looking from above. Right sensor (functioning correctly) in first pic, left sensor (malfunctioning possibly?) in second pic. I know that's not exact but does the left-side sensor in the second picture look askew? I didn't install this, purchased a previously completed airplane. Could it be wiring or soemthing else? Could a misaligned sensor cause these problems? Could the sensor be contacting the flywheel at high RPM due to vibrations? I have a professional avionics shop looking at this, just trying to help get the bird back in the air.

Thanks.