some ideas

I've been following this thread and thinking about it, although I can't say I've read every post, so apologies if someone already mentioned these.

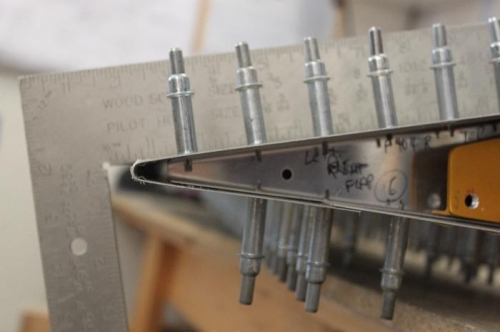

1) I do not see the tooling alignment hole in the ribs, as pictured in post #3, causing this. It is possible for air to get inside the aileron, and 'might' tend to pillow the skin a bit, but not something I think would cause the problem. Anyway, taping over the hole will eliminate this as a possibility.

2) the trailing edge, as shown in post #3, is not ideal, but I don't think it would cause the symptoms you are struggling with. It would make the ailerons very light, maybe have a kind of bi-stable behavior, where they don't want to stay perfectly neutral, but always bias slightly to one side or the other. But I doubt they would make them get very heavy at high speed.

(I can explain why the TE effects are the way they are, if anyone is interested off line).

3) The flexibility you describe by flexing the aileron with your hands on the ground - this really disturbs me. I am suspicious that the ailerons were not built as designed. Maybe they left out every other rivet for time saving, maybe they left some component out, maybe there are components inside that were not final-riveted together. Something is not right if you can manually warp the aileron.

4) there is one other item that can effect aileron feel, and that is the location of the aileron, as installed on the wing. If it is mounted just slightly high, so the aileron skin forms a contour that is slightly above the extension of the wing airfoil, that is a good thing. If it is mounted too far forward, so that both the upper and lower aileron surfaces contours nest "inside" the extended wing airfoil contours, that is a bad thing.

5) both the warping (3) and the surfaces below the wing contour (4) will effect aileron RESPONSIVENESS, and therefore indirectly the stick force. You will have to deflect them farther to get the response you expect, so the force is higher. The warping, in particular, would be very speed dependent.

Easiest thing maybe is build a new set, as you suggested. Be sure to locate them with respect to the wing as shown on the plans.