MrPilot

Member

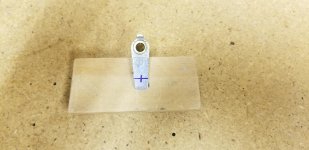

I am currently working on my practice kit and have been waiting a month already for my close quarters pop rivet dimpler to arrive from Aircraft Tool Supply. That being said, I was really wanting to make more progress and came up with a quick tool to dimple those hard to get rib holes.

1. Take a cleco clamp and disassemble.

2. Take the part of the clamp with the housing and mark 6mm up from the end. Make another mark at where the center intersects your first mark.

3. Screw the clamp housing to your work bench.

4. Drill using a #40 all the way through the clamp.

5. Counter sink until a rivet sits just under the surface.

6. Re-assemble the clamp.

7. Place a rivet into the hole to be dimpled.

8. Place the clamp over the piece to be dimpled and the rivet. The rivet shank will go through the hole in the clamp.

9. While holding the clamp, give it some taps with the rivet gun. (on the factory head side)

10. Remove the clamp and rivet.

This made an adequate dimple in the rib. It is not cframe or DRDT2 quality, but good enough for those few that any other tool can't get to.

Hope this might help someone in the future.

1. Take a cleco clamp and disassemble.

2. Take the part of the clamp with the housing and mark 6mm up from the end. Make another mark at where the center intersects your first mark.

3. Screw the clamp housing to your work bench.

4. Drill using a #40 all the way through the clamp.

5. Counter sink until a rivet sits just under the surface.

6. Re-assemble the clamp.

7. Place a rivet into the hole to be dimpled.

8. Place the clamp over the piece to be dimpled and the rivet. The rivet shank will go through the hole in the clamp.

9. While holding the clamp, give it some taps with the rivet gun. (on the factory head side)

10. Remove the clamp and rivet.

This made an adequate dimple in the rib. It is not cframe or DRDT2 quality, but good enough for those few that any other tool can't get to.

Hope this might help someone in the future.

Attachments

Last edited: