This is what I have done and my results.

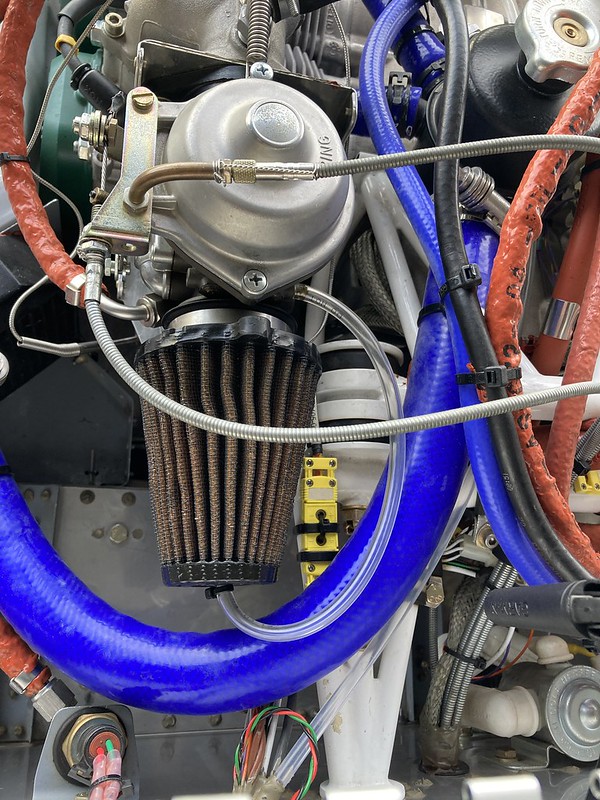

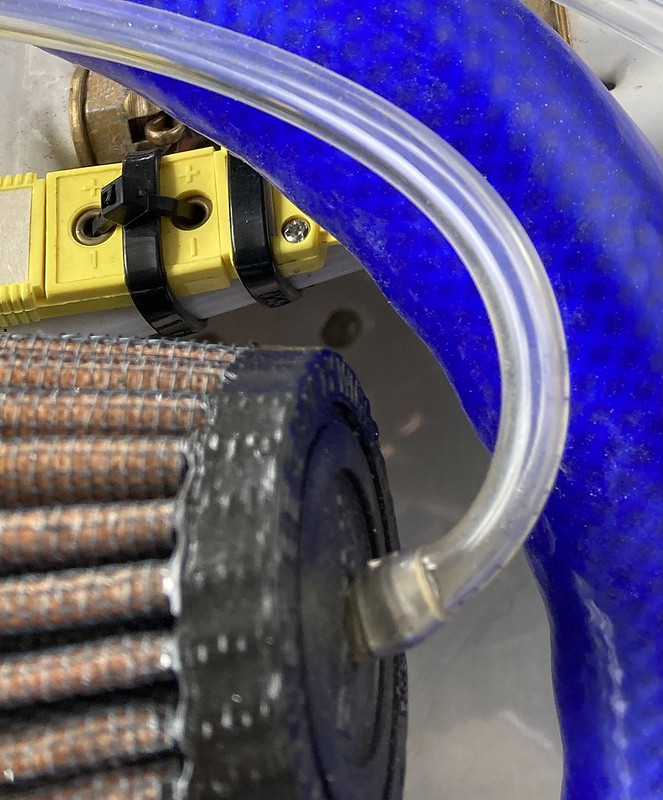

I extended the bowl vent tubes and inserted them 1” into the rear of their respective K & N air cleaners. The improvement was a smoother running engine and a GPH reduction in excess of .5GPH.

After doing the mod I flew locally and immediately could see the lower GPH on the Dynon. The power feels better but it could be subjective. I flew two flights of equal time and altitude. With fuel refill at the end to confirm the GPH was indeed lower.

The testing;

I installed 2 tubes connected to pressure sensors, the tubes came back inside the cockpit to my gauges. One tube was parallel to the stock vent tube under the carb bail alongside the existing tube. The second tube was put inside the K & N air cleaner. Both tubes were installed on the left side carburetor. I flew from 1500’ to 6000’ and at all air speeds and attitudes. During the flight the pressure reading was mostly equal on both sensors, but when it did vary the pressure at the vent tube (under the bail) was always higher in comparison to the one inside the air cleaner. My suspicion is the air swirling inside the cowl varies in pressure depending on the angle and speed that it enters the cowl.

The simple explanation;

When the air pressure above the fuel in the bowl (the vent tube) is higher than the air pressure below at the carburetor intake, it pushes down causing more fuel to go through the jets causing a richer mixture.

When the pressures are equal the carburetor meters the fuel as designed.

The carburetor vent tube is supposed to be in a location that has the same air pressure as the air entering the carburetor. A Rotax with the stock airbox has connections for the vent tubes. When the vent tubes are connected to the airbox it is in the same air that is entering the carburetor throat.

I now have 30 hours on this mod and am convinced it has made a positive improvement. With this mod I am averaging 3.8 GPH on flights averaging 110 -115 kts TAS. I fly very close to GW, typically take off from 1500’ climb to 6-7000’. My ground time averages 5 minutes, (engine is pre-warmed). I pulled the plugs after 15 hours and they were light tan, looking better than they have in the past. My EGT’s are in the low 1300’s.

I extended the bowl vent tubes and inserted them 1” into the rear of their respective K & N air cleaners. The improvement was a smoother running engine and a GPH reduction in excess of .5GPH.

After doing the mod I flew locally and immediately could see the lower GPH on the Dynon. The power feels better but it could be subjective. I flew two flights of equal time and altitude. With fuel refill at the end to confirm the GPH was indeed lower.

The testing;

I installed 2 tubes connected to pressure sensors, the tubes came back inside the cockpit to my gauges. One tube was parallel to the stock vent tube under the carb bail alongside the existing tube. The second tube was put inside the K & N air cleaner. Both tubes were installed on the left side carburetor. I flew from 1500’ to 6000’ and at all air speeds and attitudes. During the flight the pressure reading was mostly equal on both sensors, but when it did vary the pressure at the vent tube (under the bail) was always higher in comparison to the one inside the air cleaner. My suspicion is the air swirling inside the cowl varies in pressure depending on the angle and speed that it enters the cowl.

The simple explanation;

When the air pressure above the fuel in the bowl (the vent tube) is higher than the air pressure below at the carburetor intake, it pushes down causing more fuel to go through the jets causing a richer mixture.

When the pressures are equal the carburetor meters the fuel as designed.

The carburetor vent tube is supposed to be in a location that has the same air pressure as the air entering the carburetor. A Rotax with the stock airbox has connections for the vent tubes. When the vent tubes are connected to the airbox it is in the same air that is entering the carburetor throat.

I now have 30 hours on this mod and am convinced it has made a positive improvement. With this mod I am averaging 3.8 GPH on flights averaging 110 -115 kts TAS. I fly very close to GW, typically take off from 1500’ climb to 6-7000’. My ground time averages 5 minutes, (engine is pre-warmed). I pulled the plugs after 15 hours and they were light tan, looking better than they have in the past. My EGT’s are in the low 1300’s.

Last edited: