I think it's going to be a great product for STC installation on a lot of older certified airplanes. In EAB we already enjoy better equipment, not that it matters. We still tend to buy a lot of conveniences we don't strictly

need.

At the basic level, the istart system is a computer-driven square wave valve to meter fuel in response to a very simple map, which is accessible for tuning with a laptop. The metering inputs are temperature (taken from a valve cover screw location) and RPM.

RPM and temperature are also the fundamental inputs for a speed-density EFI. As an EAB owner, if I

really wanted to automate start mixture, I'd install an SDS EM-5 based EFI, and have map-controlled fuel delivery across the entire operating range.

An EFI maintains fuel pressure all the way to the point of injection, and recirculates unused fuel back to a tank, two physical facts that really damp the possibility of fuel boiling before and during hot start. The istart system pressurizes fuel only as far as the metering valve, and does not recirculate, so fuel can still boil in the flow divider and individual lines to the nozzles. It also does nothing about hot fuel being pushed into the intake manifolds after shutdown. Perhaps it doesn't matter, but these are items of technical interest.

Prefer the simplicity and electrical independence of constant flow injection? Here in EAB we routinely install electronic ignitions with large plug gaps, which tend light off a much wider range of mixtures. Although we tend to talk a lot about LOP operation after installation of an EI, there is a huge improvement is starting and idle performance. EI tends to mitigate the less precise cranking and idle fuel delivery of constant flow. Install two and things get even better.

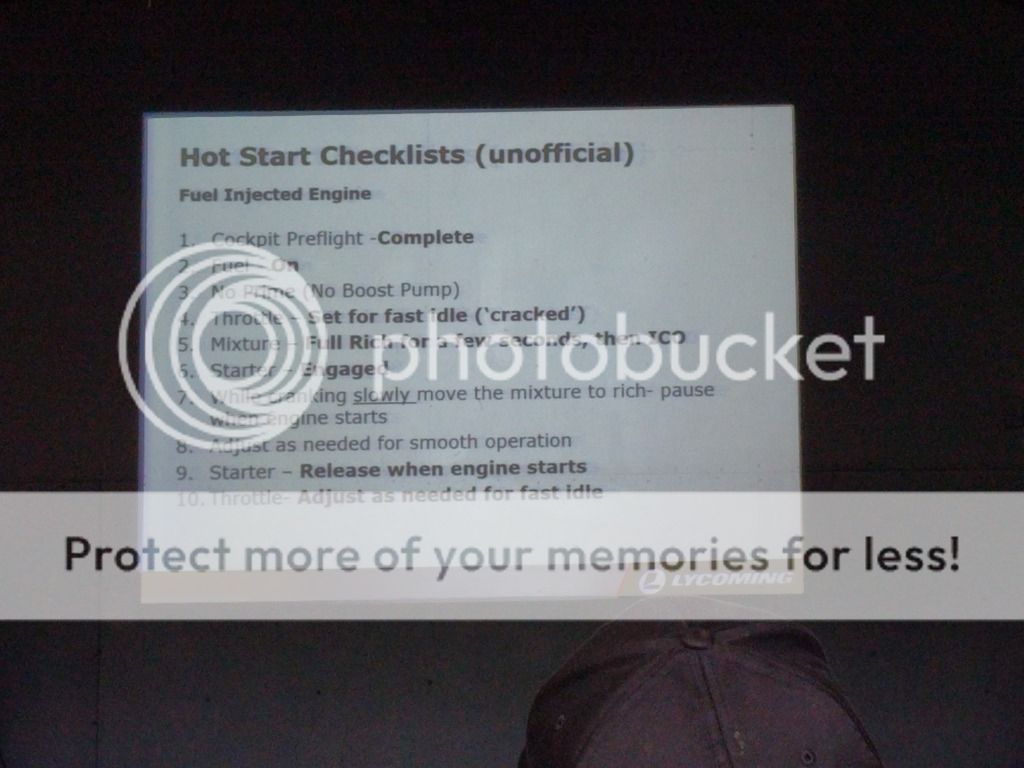

An obvious "objection" to this sort of system will be "Hey buddy, why not just learn how to start your engine?". That's not entirely fair. The truth is that

everybody misses their first shot at a hot start from time to time, and the more you know, the more you know

why.

Still, installing an istart will be a little like keeping an ugly mistress. She may may be worth the overhead, but you can't brag on her