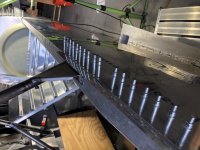

Location = Boot cowl to fuse side skin joint

Having a b*&%! of a time getting the fuse skin to "lay down" after installing the doubler for the boot cowl. Any knowledge that can be shared would be appreciated.

Looking forward. What methods/materials did you use to WX proof the boot cowl along the top of the firewall and Instrument panel bulkhead? A bunch of expensive avionics/electronics will be underneath, obviously.

Much thanks.

Views looking (mostly) down.

Having a b*&%! of a time getting the fuse skin to "lay down" after installing the doubler for the boot cowl. Any knowledge that can be shared would be appreciated.

Looking forward. What methods/materials did you use to WX proof the boot cowl along the top of the firewall and Instrument panel bulkhead? A bunch of expensive avionics/electronics will be underneath, obviously.

Much thanks.

Views looking (mostly) down.