Ivan Kristensen

Well Known Member

Just want to share my experience with y'all about Don and his staff at Airflow Performance.

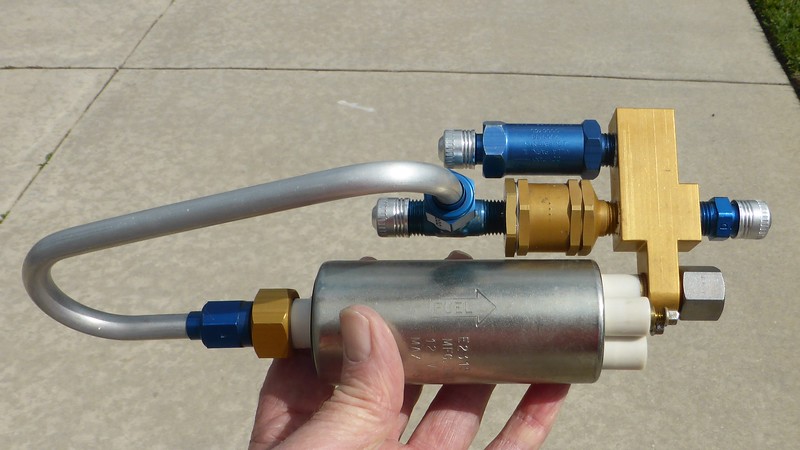

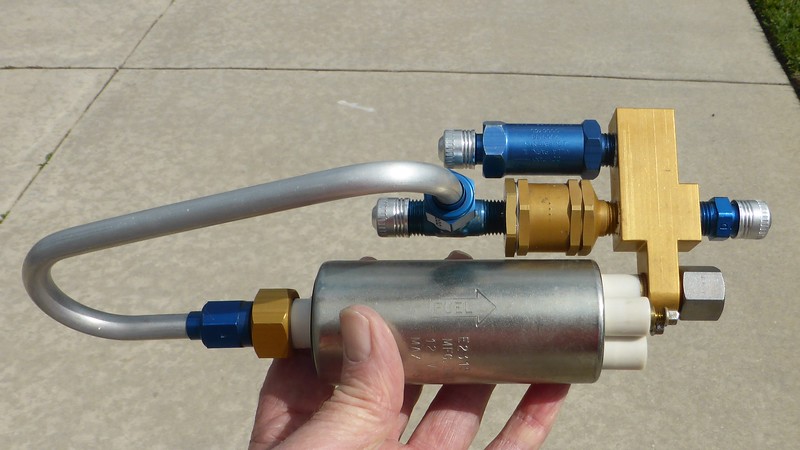

Last Sunday I went to start the engine in my RV-10. As I turned on the aux pump for the prime it immediately stopped. tried again and not a sound, upon closed examination I found that it was drawing 18A indicating that the pump had seized.

A quick call to Don at AFP early Monday morning confirmed my suspicion and he suggested that I send it back in for a pump/motor replacement.

I removed the pump from the tunnel (not an easy job) had it in overnight by 2pm. Don called me the Tuesday at 1pm to report that it was ready to send back. Charged me the cost of the pump $200.00 plus shipping, it arrived at my door at 2pm today Wednesday. 48hr turnaround.

Now THAT is what I call good service. Thank you Don.

Last Sunday I went to start the engine in my RV-10. As I turned on the aux pump for the prime it immediately stopped. tried again and not a sound, upon closed examination I found that it was drawing 18A indicating that the pump had seized.

A quick call to Don at AFP early Monday morning confirmed my suspicion and he suggested that I send it back in for a pump/motor replacement.

I removed the pump from the tunnel (not an easy job) had it in overnight by 2pm. Don called me the Tuesday at 1pm to report that it was ready to send back. Charged me the cost of the pump $200.00 plus shipping, it arrived at my door at 2pm today Wednesday. 48hr turnaround.

Now THAT is what I call good service. Thank you Don.