Veetail88

Well Known Member

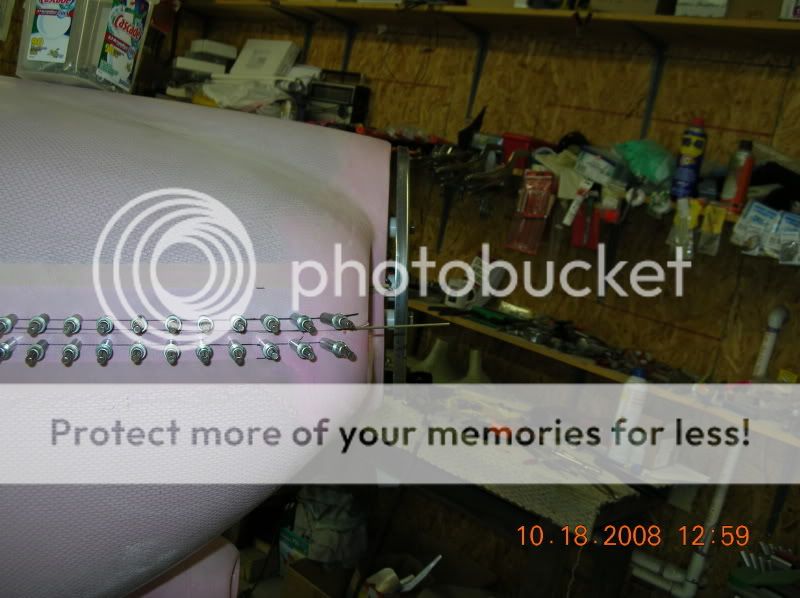

Hey folks, is this at all normal or common for a really lousy fitting cowl?

I have the back sides fitted to the firewall at the top and bottom.

From this side, it looks like the centerline of my motor is an inch or so too high, but I know that's not likely possible.

By veetail88

The other side isn't as bad, but still not good.

By veetail88

It seems to me like I'm going to have to build up 1/2" of fiberglass on the inside of the cowl face at the spinner and really grind the heck out of the thing to make the contour and fit correct.

Anyone seen this? Is there an easier fix? Am I missing something and really messing up my cowl?

Help!!

I have the back sides fitted to the firewall at the top and bottom.

From this side, it looks like the centerline of my motor is an inch or so too high, but I know that's not likely possible.

By veetail88

The other side isn't as bad, but still not good.

By veetail88

It seems to me like I'm going to have to build up 1/2" of fiberglass on the inside of the cowl face at the spinner and really grind the heck out of the thing to make the contour and fit correct.

Anyone seen this? Is there an easier fix? Am I missing something and really messing up my cowl?

Help!!