LettersFromFlyoverCountry

Well Known Member

It never fails that every year on the day the Lindy Award winners are announced, I go back to the hangar to redo something on whatever plane I'm building that I might have been generally dissatisfied with.

This year it was the fuel tank. I had used EZ Turn on fitting threads (which we used to do and consider it acceptable) and I wanted to fix that. And I did, replacing it with Permatex 2.

But in reinstalling it, I badly nicked the fuel line when trying to get a crowsfoot on the fuel line fitting at the tank. So I pulled it off, ordered new tubing and tried to remember how the heck I made that line in the first place.

Here's why.

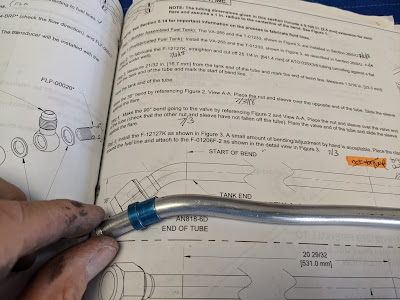

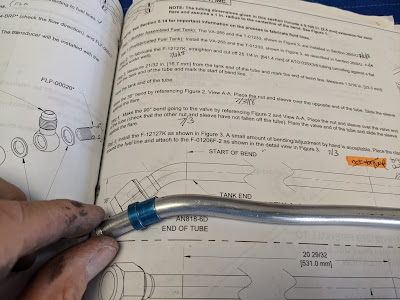

The instructions say:

1. Flare the tank end of the tube.

2. Make the bend

3. Install the nut and sleeve from the pump end of the tube.

The problem is you can't (at least *I*) can't slip a sleeve over a 38 degree bend. And yet somehow I made this line two years ago. I just can't remember what I did. (Yes, I know the sleeve is on backwards in the above photo)

Putting the collar on first and then making the bend seems problematic as the end of the bend line is 21/32" from the end of the tube.

Maybe I put the collar on, made the bend, and THEN flared the tube. I don't know.

What's the secret here?

This year it was the fuel tank. I had used EZ Turn on fitting threads (which we used to do and consider it acceptable) and I wanted to fix that. And I did, replacing it with Permatex 2.

But in reinstalling it, I badly nicked the fuel line when trying to get a crowsfoot on the fuel line fitting at the tank. So I pulled it off, ordered new tubing and tried to remember how the heck I made that line in the first place.

Here's why.

The instructions say:

1. Flare the tank end of the tube.

2. Make the bend

3. Install the nut and sleeve from the pump end of the tube.

The problem is you can't (at least *I*) can't slip a sleeve over a 38 degree bend. And yet somehow I made this line two years ago. I just can't remember what I did. (Yes, I know the sleeve is on backwards in the above photo)

Putting the collar on first and then making the bend seems problematic as the end of the bend line is 21/32" from the end of the tube.

Maybe I put the collar on, made the bend, and THEN flared the tube. I don't know.

What's the secret here?