I am up to page 22-08 where i have riveted the aileron nose ribs to the nose skin. Once the nose ribs are riveted in place, the skin really isnt very stable - is this normal?

The next step was to install the aileron spar - and learning from my flap experience, i thought i better check that there was no twist in the spar before install.

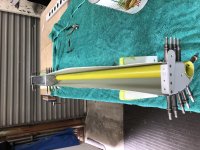

I placed it on a bench i know is perfectly flat and checked for any rocking, and twisted the spar to correct this. The winding sticks show that it is flat - no twist.

However, when i install it into the skins there is a lot of twist present. Presumably, this is caused by the skin itself - which i am not really sure how this is possible. The nose rib rivets all seemed to go in fine - some needed a little persuading, which i assumed was due to the tightness of the skin over the assembly.

All i can think if is to try and measure the twist, and correct, prior to installing the spar - but this is very difficult due to how warped the skins are without the spar in place. Or just twist the nose skin assembly an arbritraty amount and cleco the spar back on and see what happens.

Anyone have this experience or have any advice?

Overall i am finding the ailerons very challenging - lots of problems so far. It's like they are from another model or something - nowhere near as clear instructions as the rest of the kit. I'm honestly a bit frustrated.

The next step was to install the aileron spar - and learning from my flap experience, i thought i better check that there was no twist in the spar before install.

I placed it on a bench i know is perfectly flat and checked for any rocking, and twisted the spar to correct this. The winding sticks show that it is flat - no twist.

However, when i install it into the skins there is a lot of twist present. Presumably, this is caused by the skin itself - which i am not really sure how this is possible. The nose rib rivets all seemed to go in fine - some needed a little persuading, which i assumed was due to the tightness of the skin over the assembly.

All i can think if is to try and measure the twist, and correct, prior to installing the spar - but this is very difficult due to how warped the skins are without the spar in place. Or just twist the nose skin assembly an arbritraty amount and cleco the spar back on and see what happens.

Anyone have this experience or have any advice?

Overall i am finding the ailerons very challenging - lots of problems so far. It's like they are from another model or something - nowhere near as clear instructions as the rest of the kit. I'm honestly a bit frustrated.