What drives a gross weight changing with an engine size? I guess I expected the recommended gross weight to be the same for an airframe regardless of the engine in it, but the 9A has a different gross weight recommendation depending on the engine.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Explain Gross Weight for Engine Choice

- Thread starter skelrad

- Start date

RV8JD

Well Known Member

The engine horsepower would make a difference in the airplane's performance depending on maximum gross weight. That's maybe why Van's has the lower gross weight limits with smaller engines, in order to maintain their performance goals for the airplane, e.g., takeoff distance, rate of climb, etc.

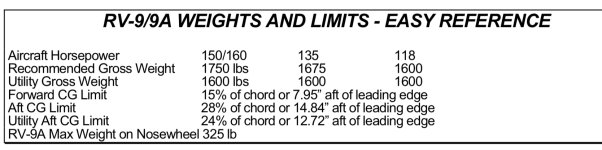

However, the Van's RV-9/-9A Weight and Balance Data Quick Reference documents only show the Recommended Gross Weight of 1750 lbs (and the Maximum Utility Category Weight of 1600 pounds), with no mention of any horsepower-dependent recommended gross weight limits.

RV-9:

RV-9A:

However, the Van's RV-9/-9A Weight and Balance Data Quick Reference documents only show the Recommended Gross Weight of 1750 lbs (and the Maximum Utility Category Weight of 1600 pounds), with no mention of any horsepower-dependent recommended gross weight limits.

RV-9:

RV-9A:

Last edited:

My DAR granted me 100 pounds over based on my IO-360 and constant speed prop. He said anything more than that, and he wanted to see some engineering and performance test data, but he would grant 100 pounds for the engine/prop combo.

Of course, when I'm loaded close to gross, I'm carrying that excess weight as fuel in the wings very near the CG line too.

Of course, when I'm loaded close to gross, I'm carrying that excess weight as fuel in the wings very near the CG line too.

rocketman1988

Well Known Member

Interesting

Interesting because as the manufacturer of the aircraft, you can assign any weight you want as long as it is tested during phase 1. Wasn't there a guy that put a 3600 lb gross on an rv-10? I had not heard of a DAR that requires engineering analysis for modifications...until now. The other question is if provided with said analysis, would the DAR have the credentials to verify the analysis?

Interesting because as the manufacturer of the aircraft, you can assign any weight you want as long as it is tested during phase 1. Wasn't there a guy that put a 3600 lb gross on an rv-10? I had not heard of a DAR that requires engineering analysis for modifications...until now. The other question is if provided with said analysis, would the DAR have the credentials to verify the analysis?

Huh. I hadn't given it a ton of thought. I just assumed the gross weight was what the airframe could physically "handle," as opposed to also making considerations for performance.

You’re not alone! Many pilots are told that gross weight is based solely on what the structure can handle, but in fact, many aircraft over history have their gross weights based on minimum climb performance.

Here in the RV world, with power-to-weight ratios that would be considered ludicrously generous in the Cessna or Piper world, it can be hard to see that - but check out the limiting performance on a C-150 on a hot day in Denver and you’ll see that they can barely climb.

So yeah….give thanks for the overpowered Rv’s, and have compassion for the folks that have to worry very day about density altitude…..

PilotjohnS

Well Known Member

Please educate me

Please educate me.

If i want to conduct phase one on my plane at a higher gross weight than what Vans recommends, what are the rules?

If I test it at a higher gross weight, can I now use that number for my gross weight after phase 1?

If analysis is needed, what analysis do i need to show?

With the inherent variability of experimental airplanes, how does one set the gross weight for a entirely scratch built airplane? Does one have to show the detailed mechanical analysis to the DAR for a one -off design to get an airworthiness certificate? Or is the flight testing sufficient?

Thanks in advance,

Please educate me.

If i want to conduct phase one on my plane at a higher gross weight than what Vans recommends, what are the rules?

If I test it at a higher gross weight, can I now use that number for my gross weight after phase 1?

If analysis is needed, what analysis do i need to show?

With the inherent variability of experimental airplanes, how does one set the gross weight for a entirely scratch built airplane? Does one have to show the detailed mechanical analysis to the DAR for a one -off design to get an airworthiness certificate? Or is the flight testing sufficient?

Thanks in advance,

Please educate me.

If i want to conduct phase one on my plane at a higher gross weight than what Vans recommends, what are the rules?

If I test it at a higher gross weight, can I now use that number for my gross weight after phase 1?

If analysis is needed, what analysis do i need to show?

With the inherent variability of experimental airplanes, how does one set the gross weight for a entirely scratch built airplane? Does one have to show the detailed mechanical analysis to the DAR for a one -off design to get an airworthiness certificate? Or is the flight testing sufficient?

Thanks in advance,

The answer is that it depends on your DAR. DAR’s can refuse to issue you a certificate if they feel that something is unsafe. So it really depends on how your DAR feels about what you’re doing. I had one DAR who felt that since I was an aeronautical engineer, he would trust my judgement (it wasn’t a gross weight thing). I had another that wanted proof from the aircraft designer that the slight increase in gross weight was acceptable for “normal category” operations. Both were reasonable requests, both reasonable responses. If someone asked a DAR to do something ridiculously out of spec with no data to back it up, I would expect them to reject the request.

The important thing is to feel your DAR out - and give him specific requests and data - long before it comes to inspection day, so you can talk about it. This will also determine if you want to proceed with that DAR or not.

The important thing is to recognize that while we’re in an Experimental category, so technically should be able to do whatever we want, we also shouldn’t be doing anything “stupid”. As long as everyone works towards “reasonable”, we should’nt adversely affect the category’s accident record…..

PilotjohnS

Well Known Member

Thanks

Paul,

thanks for your insight.

I wish there was a more concrete process for establishing a higher gross weight; this loosey-goosey stuff and shopping for a DAR bothers me.

Paul,

thanks for your insight.

I wish there was a more concrete process for establishing a higher gross weight; this loosey-goosey stuff and shopping for a DAR bothers me.

Paul,

thanks for your insight.

I wish there was a more concrete process for establishing a higher gross weight; this loosey-goosey stuff and shopping for a DAR bothers me.

There is no loosey goosey. To my knowledge, the only one who has done true engineering analysis and destructive testing is Vans and they are crystal clear on what the limit is with no exceptions. Many arm chair Engineers have said "oh that's conservative, so no harm increasing it some." With this kind of engineering, it's all about safety margins between rated and actual structural limits and these margins have to account for all sorts of unplanned things that were not in the structural load engineering. Eat into those margins and fewer of those things can be in place and still avoid structural failure. That said, these things don't happen often and statistics reflect that.

As a builder, you can set what you want, depending upon inspector criteria, but to do so without understanding the consequences puts you and your family at some level of risk. Problem is no one other than Van's can really can quantify that risk and am not even sure they can quantify it, as I believe they are using generally accepted aviation standards for the margins. Though it is possible that they extended those margins further to account for builder flaws that can be expected in EAB that are not generally seen in certified. This is one of my guesses as to why the 6 has a lower GW rating than the 7 (home built spar vs factory built spar), but that is pure speculation and have nothing to base that on.

Larry

Last edited:

Mikeyb

Well Known Member

To me building a well proven Vans kit meant that the only thing that was experimental about it was that I built it. I never imagined someone would go outside the W/B envelope. I don’t think an airplane built to operate outside those limits should be registered as an RV.

Last edited:

Larry is right on.

Arbitrarily choosing to increase specific performance limits, whether it be speed, weight, etc., is a kin to you doing all the work to design your own airplane and then once it is built simply make the conscious choice to up some of the limits beyond those that you used when doing all of the engineering and design work for said airplane.

Wouldn’t make much sense would it?

The design limits specified by vans are the design limits. Anyone making a choice to go beyond them just because they don’t meet their personal needs, is degrading their and their passengers safety margins.

As for the difference in the RV-6 and RV-7 design gross weight… The RV-7 is higher because it was specifically designed to be higher. The purpose of the RV-7 design was to be an improved and updated version of the RV-6. Wanting a larger (heavier) engine and higher payload carrying ability were two of the things that customers mentioned most regarding the RV-6, so those were taken into consideration when the engineering of the RV-7 was done.

Arbitrarily choosing to increase specific performance limits, whether it be speed, weight, etc., is a kin to you doing all the work to design your own airplane and then once it is built simply make the conscious choice to up some of the limits beyond those that you used when doing all of the engineering and design work for said airplane.

Wouldn’t make much sense would it?

The design limits specified by vans are the design limits. Anyone making a choice to go beyond them just because they don’t meet their personal needs, is degrading their and their passengers safety margins.

As for the difference in the RV-6 and RV-7 design gross weight… The RV-7 is higher because it was specifically designed to be higher. The purpose of the RV-7 design was to be an improved and updated version of the RV-6. Wanting a larger (heavier) engine and higher payload carrying ability were two of the things that customers mentioned most regarding the RV-6, so those were taken into consideration when the engineering of the RV-7 was done.

I was mostly curious why gross weight recommendations would change with different engines on the same airframe, but I didn't realize people played around with the numbers beyond those recommendations. Searching on the topic now, it looks like something that has been beat around a bit. Huh.

I was mostly curious why gross weight recommendations would change with different engines on the same airframe, but I didn't realize people played around with the numbers beyond those recommendations. Searching on the topic now, it looks like something that has been beat around a bit. Huh.

Yes it has.

Some have a true understanding of why the limits are what they are, and some choose to consider it a suggestion (even though it is far from that).

The different gross weights on the RV-9 are indeed related to climb performance.

Even though as a kit manufacturer we are not required to design to FAR requirements, they are used as guidelines for many design parameters on RV kits because most of those requirements exist for very good reasons.

When discussing “design margins”, “safety factors”, or more properly “factors of ignorance”, most builders do not understand that they do not own these. The only one that owns these is the design engineer. He (or she) is the only one that understands the assumptions, simplifications, and design standards used to create the structure. In general, he is the one that designs the physical test regime, either ground or flight based, and signs off that the structure meets or exceeds the design standards.

In airplane design, the load factors are specified based on the category of airplane. In the GA certified world, these are normal, utility and aerobatic. Applying these load factors to the weight of the airplane results in the limit load. For example, the positive limit load of an aircraft in the aerobatic category with an aircraft weight of 1600 lbs is (1600lb x 6 g load factor) = 9600 lbs. On top of this limit load, a “safety factor” of usually 1.5 is applied to give the design ultimate load. So, in the example case, (9600 lbs x 1.5) = 14,400 lbs. This is the point at which the structure is about to fail catastrophically.

While normally called a “safety factor”, this is really a catch all for “factors of ignorance”. It includes such things as: defects in the material (aluminum sheet and plate in the case of RVs), defects in manufacture, defects in service, etc. All those things that the designer cannot control.

So whenever I read in these forums about builders installing larger engines than recommended, selecting an arbitrary gross weight above that recommended, flying at a speed that exceeds Vne, or pulling more Gs than the airplane was designed for, I ask myself what have they done to ensure the safety of the airplane? Have they done any calculations? Have they done any testing? In most cases, I suspect the answer is no.

The designer is the only one that owns the “design margins”. Not the builder, not the pilot, not the mechanic. Any builder that encroaches on the “design margins” is showing their own ignorance.

In airplane design, the load factors are specified based on the category of airplane. In the GA certified world, these are normal, utility and aerobatic. Applying these load factors to the weight of the airplane results in the limit load. For example, the positive limit load of an aircraft in the aerobatic category with an aircraft weight of 1600 lbs is (1600lb x 6 g load factor) = 9600 lbs. On top of this limit load, a “safety factor” of usually 1.5 is applied to give the design ultimate load. So, in the example case, (9600 lbs x 1.5) = 14,400 lbs. This is the point at which the structure is about to fail catastrophically.

While normally called a “safety factor”, this is really a catch all for “factors of ignorance”. It includes such things as: defects in the material (aluminum sheet and plate in the case of RVs), defects in manufacture, defects in service, etc. All those things that the designer cannot control.

So whenever I read in these forums about builders installing larger engines than recommended, selecting an arbitrary gross weight above that recommended, flying at a speed that exceeds Vne, or pulling more Gs than the airplane was designed for, I ask myself what have they done to ensure the safety of the airplane? Have they done any calculations? Have they done any testing? In most cases, I suspect the answer is no.

The designer is the only one that owns the “design margins”. Not the builder, not the pilot, not the mechanic. Any builder that encroaches on the “design margins” is showing their own ignorance.

Dan 57

Well Known Member

The designer is the only one that owns the “design margins”.

Absolutely.

And obscure by itself... assume we'd take 2 team of Engineers, and have them recalculate, both of them and separetely , e.g. the RV-6 and the RV-7, using non-empirical methods as used in modern analysis... my bet is that the results would be quite interesting.

As to the -9(A) having different Gross Weights for different engines... bizarre, as most other models also have different engine/power options, but only one Gross Weight (Mass really, but that is another subject in itself)...

Absolutely.

And obscure by itself... assume we'd take 2 team of Engineers, and have them recalculate, both of them and separetely , e.g. the RV-6 and the RV-7, using non-empirical methods as used in modern analysis... my bet is that the results would be quite interesting.

As to the -9(A) having different Gross Weights for different engines... bizarre, as most other models also have different engine/power options, but only one Gross Weight (Mass really, but that is another subject in itself)...

There are multiple factors that set a specific gross weight limit.

For most of the RV models that is mass because if even the smallest recommended engine is used the airplane will still meet all of the other performance criteria (rate of climb at gross, etc.)

For the RV-9 the different gross weight limit with the smaller engines isn't because the airframe structure can't handle the higher load (because it is exactly the same structurally), In that case as already mentioned, it is because if flown at the normal max. gross weight with the smaller engine, the airplane would not be capable of a minimum rate of climb (particularly with the high pitch fixed pitch prop that likely would be used to achieve the high cruise speed that the airplane is capable of).

rmarshall234

Well Known Member

PilotjohnS

Well Known Member

Same thing, different feelings

So i raised the question and started this thread drift, sorry , but happy it went there.

So a builder can artificially increase the gross weight in two ways:

1) The builder can apply for airworthiness and do the phase 1 testing with a higher than recommended gross weight.

2) The builder can do all the airworthiness stuff as recommended by the manufacturer. Then, when his mission demands, he can concisely and deliberately overload the airplane.

Either way is the same bad outcome, except the first way the pilot may feel better because he "Certified it" at the erroneous overweight gross weight.

So what I hear you all saying is that certifying the plane at a higher gross weight is just as bad as intentionally taking off "over gross"?

So i raised the question and started this thread drift, sorry , but happy it went there.

So a builder can artificially increase the gross weight in two ways:

1) The builder can apply for airworthiness and do the phase 1 testing with a higher than recommended gross weight.

2) The builder can do all the airworthiness stuff as recommended by the manufacturer. Then, when his mission demands, he can concisely and deliberately overload the airplane.

Either way is the same bad outcome, except the first way the pilot may feel better because he "Certified it" at the erroneous overweight gross weight.

So what I hear you all saying is that certifying the plane at a higher gross weight is just as bad as intentionally taking off "over gross"?

rmarshall234

Well Known Member

I think it is worse. Because as the "manufacturer", you just made the miscalculation for the next owner(s) in line.

Back in my 135 air taxi days in Alaska, we were legally allowed to increase the gross weight of our aircraft.

FAR 91.0323 (b) The maximum certificated weight approved under this section may not exceed - (2) 115 percent of the maximum weight listed in the FAA aircraft specifications.

EDIT: On a 3300lb. Cessna 185, Thats a 495lb. increase

I'm not saying we should do this with our RVs but the FAA doesn't draw a clear line on gross weight for some certified aircraft under some operations. They certainly didn't do an engineering study, as this applied to most air taxi aircraft in use at the time regardless of manufacturer.

My point is, gross weight may not be such a hard and fast number backed by engineering as some seem to indicate.

FAR 91.0323 (b) The maximum certificated weight approved under this section may not exceed - (2) 115 percent of the maximum weight listed in the FAA aircraft specifications.

EDIT: On a 3300lb. Cessna 185, Thats a 495lb. increase

I'm not saying we should do this with our RVs but the FAA doesn't draw a clear line on gross weight for some certified aircraft under some operations. They certainly didn't do an engineering study, as this applied to most air taxi aircraft in use at the time regardless of manufacturer.

My point is, gross weight may not be such a hard and fast number backed by engineering as some seem to indicate.

Last edited:

In airplane design, the load factors are specified based on the category of airplane. In the GA certified world, these are normal, utility and aerobatic. Applying these load factors to the weight of the airplane results in the limit load. For example, the positive limit load of an aircraft in the aerobatic category with an aircraft weight of 1600 lbs is (1600lb x 6 g load factor) = 9600 lbs. On top of this limit load, a “safety factor” of usually 1.5 is applied to give the design ultimate load. So, in the example case, (9600 lbs x 1.5) = 14,400 lbs. This is the point at which the structure is about to fail catastrophically.

While normally called a “safety factor”, this is really a catch all for “factors of ignorance”. It includes such things as: defects in the material (aluminum sheet and plate in the case of RVs), defects in manufacture, defects in service, etc. All those things that the designer cannot control.

Terry is correct but one other thing to be aware of is that in aviation at limit load (no safety factor), the structure is allowed to deform permanently, it just cannot fail. Therefore if you exceed limit load (or sometimes called design to load) you should perform an inspection looking for deformed, crumbled, bent, crinkled, wrinkled or maybe even a crack in the structure. That is what is done on commercial and military aircraft. The safety factor, when applied to get to design ultimate load, allows for that gray zone of strength analysis between plastic deformation and when failure occurs. Look at a stress/strain curve and you will see that fracture does not happen at max stress and strain (deformation) is no longer linear with stress. And once you have deformation all bets are off as seen in the stress/strain curve, the structure may no longer be capable of carrying design limit load the next occurrence (ie the structure gets weaker)

Last edited:

So what I hear you all saying is that certifying the plane at a higher gross weight is just as bad as intentionally taking off "over gross"?

Mechanically, there is no difference.

Back in my 135 air taxi days in Alaska, we were legally allowed to increase the gross weight of our aircraft.

FAR 91.0323 (b) The maximum certificated weight approved under this section may not exceed - (2) 115 percent of the maximum weight listed in the FAA aircraft specifications.

EDIT: On a 3300lb. Cessna 185, Thats a 495lb. increase

Except it is now and never has been legal to do with a Cessna 185 (If I understand FAR 91.323 correctly).

It is only allowed on specific older aircraft that were originally certificated under the Department of Commerce, and later the CAA, and even then it is under very specific requirements that are not relevant for privately operated aircraft.

In my opinion not at all relevant to modern aircraft, RV's included.

If interested, people should do a bit of research on the origins of why this was allowed. My take is that it was a willingness to trade some levels of safety in order to increase others.

Except it is now and never has been legal to do with a Cessna 185 (If I understand FAR 91.323 correctly).

It is only allowed on specific older aircraft that were originally certificated under the Department of Commerce, and later the CAA, and even then it is under very specific requirements that are not relevant for privately operated aircraft.

In my opinion not at all relevant to modern aircraft, RV's included.

If interested, people should do a bit of research on the origins of why this was allowed. My take is that it was a willingness to trade some levels of safety in order to increase others.

Without going into the intricacies of the FAR...when doing the oral on a 135 check ride and asked to do a weight and balance, the 115% rule indeed was allowed for C-185s, C-206s, Cub's and whenever else we flew. At least in the '90s, this rule was applied across all bush planes regardless of the vintage.

That being said...As I indicated in my original post, I'm not advocating this for our RVs and I am personally adhering to the Van's published gross weight for my build...

This example was illustrated to show that the gross weight was not a hard line in the eyes of the FAA.

Record Breakers

For most of my life I have been fascinated by long distance flights in small airplanes, starting with Max Conrad in the early 60s. Currently Bill Harrelson's record breaking flights have been of interest. Guam to Jacksonville FL, 7038nm nonstop, a new world record.

I think all those airplanes may have been a bit over gross. Maybe two times the normal gross.

For most of my life I have been fascinated by long distance flights in small airplanes, starting with Max Conrad in the early 60s. Currently Bill Harrelson's record breaking flights have been of interest. Guam to Jacksonville FL, 7038nm nonstop, a new world record.

I think all those airplanes may have been a bit over gross. Maybe two times the normal gross.

For most of my life I have been fascinated by long distance flights in small airplanes, starting with Max Conrad in the early 60s. Currently Bill Harrelson's record breaking flights have been of interest. Guam to Jacksonville FL, 7038nm nonstop, a new world record.

I think all those airplanes may have been a bit over gross. Maybe two times the normal gross.

Different animal there - those are being done under ferry permits - a specific one-time-only exemption for some particular reason.

Without going into the intricacies of the FAR...when doing the oral on a 135 check ride and asked to do a weight and balance, the 115% rule indeed was allowed for C-185s, C-206s, Cub's and whenever else we flew. At least in the '90s, this rule was applied across all bush planes regardless of the vintage.

All I know is the first paragraph implies it is aircraft vintage specific.

Just because it is “what was done” doesn’t mean it was correct.

Certification

I think the Conrad Comanche's were probably Experimental research and development.

The Lancair may have only required testing for the proposed gross weight.

Harrelson beat a solo around the world record held by Conrad for decades.

The Conrad single Commanche is in the museum in Liberal KS, with all the tanks. I got to sit in The Conrad Twin Commanche with all the tanks installed.

The right seat was a tank with a thin piece of foam. No visibility to the left. I can't comprehend sitting in that airplane for close to 60 hours.

I think the Conrad Comanche's were probably Experimental research and development.

The Lancair may have only required testing for the proposed gross weight.

Harrelson beat a solo around the world record held by Conrad for decades.

The Conrad single Commanche is in the museum in Liberal KS, with all the tanks. I got to sit in The Conrad Twin Commanche with all the tanks installed.

The right seat was a tank with a thin piece of foam. No visibility to the left. I can't comprehend sitting in that airplane for close to 60 hours.

Conrad

Conrad used the Twin Commanche as a personal airplane after the record flight. It still had the tanks. I don't think anyone knew or cared what his gross weight was. If he was in NY and wanted to go to CA his inclination was to put in a bunch of fuel and go nonstop. TC will go coast to coast on a bit over 200 gallons, with IFR reserves.

Another interesting thing is that on the single and twin Commanche's the tip tank fuel gets a "free ride" gross weight goes up by the weight of the tanks and fuel. Only 30 gallons so not a big deal.

Conrad used the Twin Commanche as a personal airplane after the record flight. It still had the tanks. I don't think anyone knew or cared what his gross weight was. If he was in NY and wanted to go to CA his inclination was to put in a bunch of fuel and go nonstop. TC will go coast to coast on a bit over 200 gallons, with IFR reserves.

Another interesting thing is that on the single and twin Commanche's the tip tank fuel gets a "free ride" gross weight goes up by the weight of the tanks and fuel. Only 30 gallons so not a big deal.

all this talk about the design engineer owning the margin

and the idea about factors of safety.

One important reason for factor of safety that unless I missed it I don't believe was mentioned....and that's the engineer makes mistakes too.... they can't think of everything...and yes, we are very often overly conservative too.

Sometimes a larger FS is applied to some components while a smaller FS might be applied to other systems in the same aircraft. How that all meshes together is often outside the comprehension of even the design engineer. Often rules of thumb get applied that might have a tight FS for some situations but be extremely over conservative at the same time. It can be complex for sure.

We hope at least, that the designer....or more likely the design team... has considered everything that is realistically possible to consider and made the best compromise decisions along the way. Without having the full big picture someone doing a modification is making some blind assumptions for sure....but it might not necessarily be wrong/dangerous/stupid/or whatever....

I'm left remembering a term I'd heard in a seminar once a very long time ago..."Star Trek Engineering...going where no man has gone before."

and the idea about factors of safety.

One important reason for factor of safety that unless I missed it I don't believe was mentioned....and that's the engineer makes mistakes too.... they can't think of everything...and yes, we are very often overly conservative too.

Sometimes a larger FS is applied to some components while a smaller FS might be applied to other systems in the same aircraft. How that all meshes together is often outside the comprehension of even the design engineer. Often rules of thumb get applied that might have a tight FS for some situations but be extremely over conservative at the same time. It can be complex for sure.

We hope at least, that the designer....or more likely the design team... has considered everything that is realistically possible to consider and made the best compromise decisions along the way. Without having the full big picture someone doing a modification is making some blind assumptions for sure....but it might not necessarily be wrong/dangerous/stupid/or whatever....

I'm left remembering a term I'd heard in a seminar once a very long time ago..."Star Trek Engineering...going where no man has gone before."

newt

Well Known Member

have compassion for the folks that have to worry very day about density altitude…..

Nah.

- mark

We hope at least, that the designer....or more likely the design team... has considered everything that is realistically possible to consider and made the best compromise decisions along the way. Without having the full big picture someone doing a modification is making some blind assumptions for sure....but it might not necessarily be wrong/dangerous/stupid/or whatever....

It all starts with what are the loads on the aircraft and then how are those loads distributed throughout the airframe. In my 37 years of aircraft design, loads can be one of the most debated things within the structural design team.

If we fly above gross weight used in the analysis then the starting load number is higher to be distributed down to individual parts. If we make mods to the original design then the distribution of the loads to individual parts changes. If you fly above gross weight with a modified design, loads on individual parts can be completely different than the analysis and testing performed on the original design.

rocketman1988

Well Known Member

How

With all the talk about engineering, I am wondering how anybody ever survived without a full structural analysis, CFD run, stability and control program, and a certified engine…

Tic

With all the talk about engineering, I am wondering how anybody ever survived without a full structural analysis, CFD run, stability and control program, and a certified engine…

Tic

Not sure which era you are referring to. I the early era, analysis was a bit light, and the proof was in the flight testing. This was the era of the test pilot and a lot of them were killed doing the testing. Little was understood about spins and structure and control surface flutter. Later, ground based static testing started to eliminate some of the in flight failures. As more research was done, materials were better understood, as were loads, gusts and so on. Today, calculators and computers have replaced the slide rule, and CFD is used to validate wind tunnel testing and vice versa. Now, the design and analysis disciplines have a much better understanding and flight test is much safer. Engineers use all the tools available to design safe machines.

The engineering process has always been design, analyze, build, and test, then go back to the beginning as needed (but I'm sure you know this).

The engineering process has always been design, analyze, build, and test, then go back to the beginning as needed (but I'm sure you know this).

rocketman1988

Well Known Member

Yep

Yes, I know, hence the Tic…

Yes, I know, hence the Tic…