scsmith

Well Known Member

I have an aluminum 5/8" diameter breather pipe running down my firewall, perfectly bent to terminate just above the exhaust pipe, just how I like it.

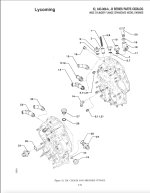

The engine breather fitting is a 3/4" tube fitting on the accessory case.

I have a 3/4" i.d. to 5/8" i.d molded rubber elbow on that fitting, then a short section of aluminum tube, then a 5/8" molded rubber elbow that connects to the aluminum tube running down my firewall. All is great, except.....

The two molded rubber elbows are heater hose, not PCV/emissions hose. They are not very resistant to oil. So after a few years, they are kind of swollen and sweat oil on the outside a little bit. So I have just been changing them every couple of years.

But wouldn't it be nice if I could find molded rubber elbows in PCV hose (not to be confused with PVC ) that was the right size?

) that was the right size?

Ideas?

I'm more than a little reluctant to change the tube fitting on the engine, it is a very lightweight fitting, and it was installed into the accessory case when the engine was first built, probably before humans walked on the moon. My hunch is that if I put a socket on that fitting and try to unscrew it, it will rumble and buckle into a mess.

Does anyone know the I.D. of the molded hose that Van's sells for breathers? If it is 5/8", that would at least solve half my problem.

The engine breather fitting is a 3/4" tube fitting on the accessory case.

I have a 3/4" i.d. to 5/8" i.d molded rubber elbow on that fitting, then a short section of aluminum tube, then a 5/8" molded rubber elbow that connects to the aluminum tube running down my firewall. All is great, except.....

The two molded rubber elbows are heater hose, not PCV/emissions hose. They are not very resistant to oil. So after a few years, they are kind of swollen and sweat oil on the outside a little bit. So I have just been changing them every couple of years.

But wouldn't it be nice if I could find molded rubber elbows in PCV hose (not to be confused with PVC

Ideas?

I'm more than a little reluctant to change the tube fitting on the engine, it is a very lightweight fitting, and it was installed into the accessory case when the engine was first built, probably before humans walked on the moon. My hunch is that if I put a socket on that fitting and try to unscrew it, it will rumble and buckle into a mess.

Does anyone know the I.D. of the molded hose that Van's sells for breathers? If it is 5/8", that would at least solve half my problem.

Last edited: