At Reno the Sport class races the RVs that enter ar in the large hangar next to the street that runs by the south side of the airport and there is a no prop turn rule until the plane is spotted on the ramp adjacent to the taxiway a significant distance away (1/8 to 1/4 mile). Tow vehicles operated by the race staff move the planes to the assigned spots. Typically these are tail draggers and the tail wheel is run up an little ramp on the tow bar and it drops into a recess and that is the tow link. That doesn't work with an RV-6A for example. When I was there last year I was not in the race but one of the racers had a structural failure and had to be moved to the private hangar where my plane was being kept at the east end of the hangars and mine had to be moved to the Sport Class Bronze hangar.

When the first tow was completed to move the damaged plane we found two compatibility problems:

1 - the nose gear fairing which has only a 0.75" ground clearance could not clear the tow bar structure to allow the nose wheel to roll up the ramp or drop into the wheel recess without damaging the fairing.

2 - if the fairing was removed (a tedious process involving around 20 screws) the nose strut would not clear the the tow bar structure forward of the wheel recess.

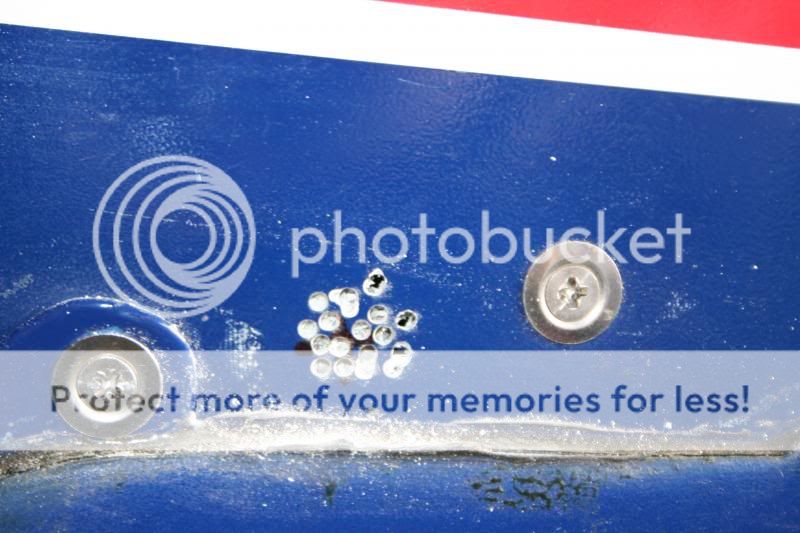

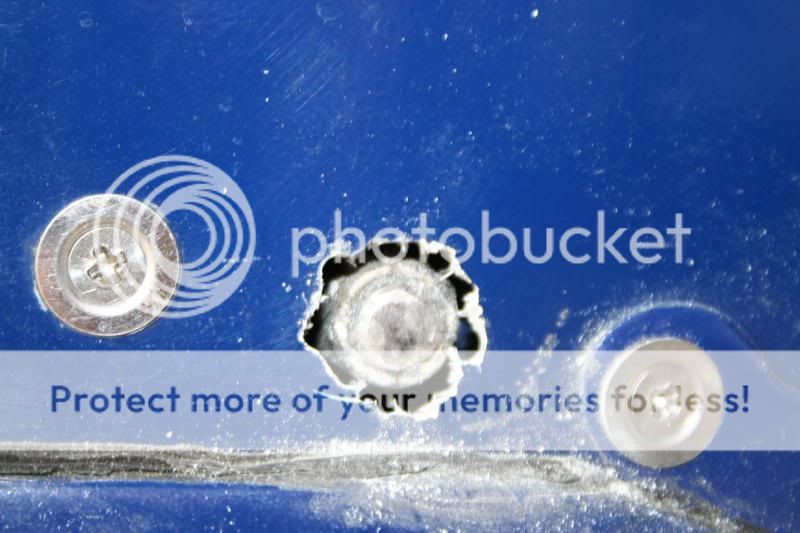

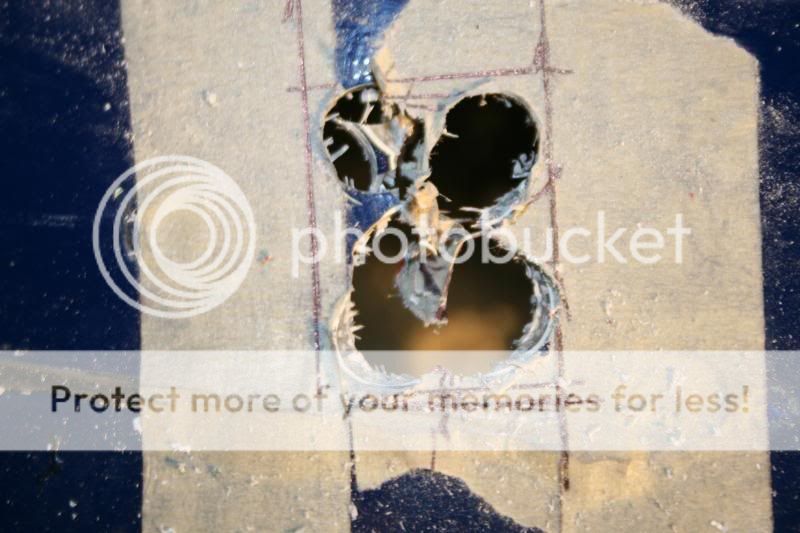

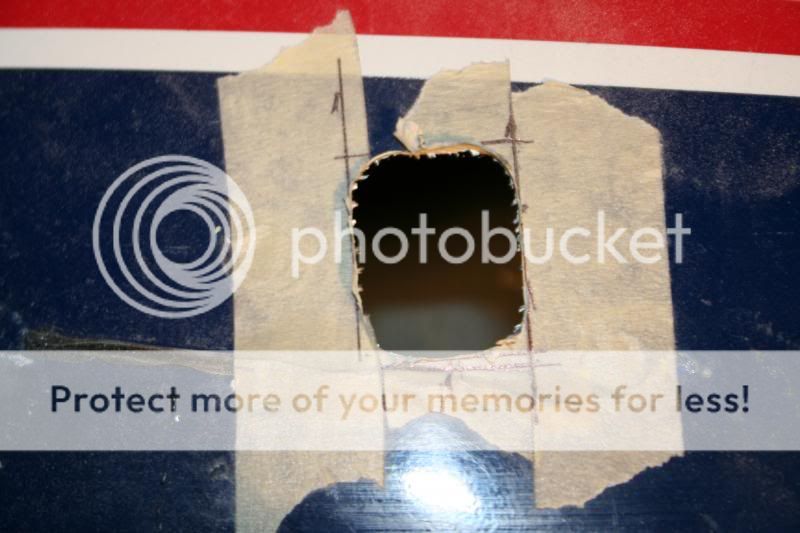

I pressed down on the stabilizer and raised the nos wheel off of the ground and the tow operator backed the tow bar under the wheel and I let it down into the recess. That enabled the long move to be completed but that is not compatible with race operations scheduling, etc. I have developed external covers for other applications and speed mods and I plan to cut a hole in each side of the nose wheel fairing and develop covers requiring only one screw for installation and removal - similar to my fresh air vent covers - to provide access to the axle hardware that people currently use for towing. I would buy one of those tow bars that people currently use, cut off the handle and replace it with a ring or something compatible with the tow vehicle tow connection.

The question is what tow bar is compatible with the RV-6A axle hardware? I want to buy something that is known to work with the airplane and modify it to be compatible with the tow vehicle.

Bob Axsom

When the first tow was completed to move the damaged plane we found two compatibility problems:

1 - the nose gear fairing which has only a 0.75" ground clearance could not clear the tow bar structure to allow the nose wheel to roll up the ramp or drop into the wheel recess without damaging the fairing.

2 - if the fairing was removed (a tedious process involving around 20 screws) the nose strut would not clear the the tow bar structure forward of the wheel recess.

I pressed down on the stabilizer and raised the nos wheel off of the ground and the tow operator backed the tow bar under the wheel and I let it down into the recess. That enabled the long move to be completed but that is not compatible with race operations scheduling, etc. I have developed external covers for other applications and speed mods and I plan to cut a hole in each side of the nose wheel fairing and develop covers requiring only one screw for installation and removal - similar to my fresh air vent covers - to provide access to the axle hardware that people currently use for towing. I would buy one of those tow bars that people currently use, cut off the handle and replace it with a ring or something compatible with the tow vehicle tow connection.

The question is what tow bar is compatible with the RV-6A axle hardware? I want to buy something that is known to work with the airplane and modify it to be compatible with the tow vehicle.

Bob Axsom