Help session

Hi Andy,

We need more RV-4 action on this forum, so I'll pitch in to assist you.

The side skirts are difficult at first, but you shouldn't give up; light weight, looks good, stock design.

I happened to take a few photos of my canopy build, so here goes with my method...

1)

Helping hands - I temporarily adhered some wood blocks with foam tape on the fuse sides to rest the skirt on. The blocks have a slight rabbit slot to facilitate holding the skirt. This enables you to quickly position it on the frame over and over again -- in the same exact location. The bottom straight edge of the skirt is your starting point; no trimming. Make the blocks longer than I did, so they don't accidentally fall off as easily.

2)

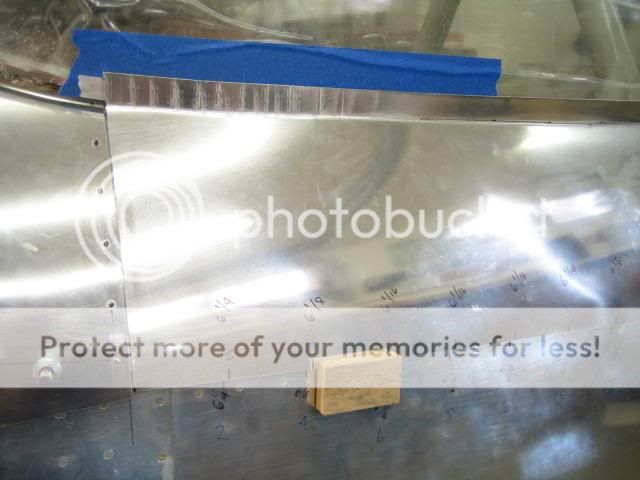

Lofting the bend line - With the skirt in place on the blocks, draw a line on the fuse at the bottom of the skirt so you can measure up to the bend line on the plexi, which is just below the round aluminum frame. Draw the bend line on the canopy Plexiglas (masking tape). With the skirt

off the frame, and using a flexible metal ruler, measure up to the bend line on the canopy Plexiglas every two inches, and write it on the fuse at the measurement station. Now put the skirt back on the blocks and measure up and mark a dot with your Sharpie pen. By connecting the dots you have established the bend line. You will have to trim the top of the skirt to create a uniform flange width that rests on the plex. Do not do any trimming to the aft skirt yet. Trim to the proper flange width (+-18mm?), and start forming the bend with your roller tool (Avery has them). Go slow and test fit on your blocks frequently. Work both sides at the same time, and take advantage of your skills as they improve.

3)

Finish both sides of the front section - Once you have the front section on both sides cut, flange formed and trimmed, move on to the to the aft. Same process... draw lofting dots from an established point on the fuse. Look at the photo; with the skirt off, I drew a straight line on the fuse, up to the bend line. The aft canopy skirt tends to rise up as you work toward the tail, so don't get carried away with aggressive trimming. Keep test fitting both sides and bend them into position to make sure the tails are on target. In one of the photos you can see the un-trimmed skirt to the right of my hand. I'm slowly working my way aft a few inches at a time. Near the tail, the flange bend stops. Once you get to the tail, trim them to mate. I used a doubler at the tail seam.

Finally, it took me two weeks of evenings to do it the first time, but it wasn't that great. I ordered another set of skins, and did it the second time around in one weekend. To be honest, the photos document my second go-around at the skirts, so don't get down on yourself. After all said and done, my skirt was too tight against the fuse turtle deck, so I trimmed by sanding block and emery cloth. After painting the fuse I had to trim slightly more. I think canopy cracks are often caused by too much stress when the canopy locked down.

I hope this helps

Sincerely, Brian