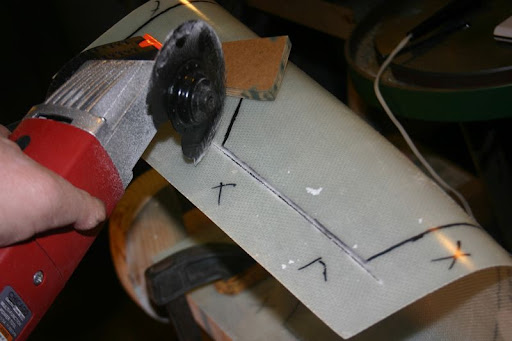

Here is the last of the pictures of the tail cone construction.

http://picasaweb.google.com/JimCone1941/RV12TailConstruction11209#

http://picasaweb.google.com/JimCone1941/RV12TailConstruction11209#

Jim,

How did you get the tail cone halves? My plans say they won't be shipped until the "Finish" kit.

John

Jim, Photo #6 shows 5 rivets on the aft verticle stabilizer spar (center of the picture) that have not been riveted. I found the print does not instruct us to rivet these. Clearly, they should be riveted with the blind rivets. Also, behind the rudder (aft vert stabilizer spar, again) did you rivet all of the holes yet? There were about 30 that had not been riveted when I got done. I re-read the plans and could not find where it says finish rivet all holes. I pulled the rudder and finished it up.

Any thoughts?

Good catch! I just figured that those holes would be riveted when the tail cone fairing was mounted. I will check with Van's before I rivet them. BTW, I got my fairing when I picked up the kit.

Jim, Photo #6 shows 5 rivets on the aft verticle stabilizer spar (center of the picture) that have not been riveted. I found the print does not instruct us to rivet these. Clearly, they should be riveted with the blind rivets. Also, behind the rudder (aft vert stabilizer spar, again) did you rivet all of the holes yet? There were about 30 that had not been riveted when I got done. I re-read the plans and could not find where it says finish rivet all holes. I pulled the rudder and finished it up.

Any thoughts?

Hi Jim,

Thank you very nice.

How many hours did you spend on the tailkit?

Rudi

Nice job on the fiberglass Jim. I did not get any of the glass with the kit, still waiting. Nice to see some pics of how to set it up.

It took 74 hours. That includes priming and finishing the VS and Rudder tips and sanding to 2000 grit sandpaper to make them as smooth as glass. It does not include the tail cone fairing finishing, as I ran out of pin hole filler. It will probably take 3 to 4 hours to get that one like the tips.

Jim,

Again thanks for your photos. Have a request. Could you list the steps (maybe a short tutorial) and products you used to finish the fiberglass components. It will be a NEW process that I have to learn and certainly want to do it right.

They are included in my tail kit bill of materials, but they are listed as back ordered. I called in yesterday and Van's said that they would not be in until the end of the month. I hope they are not in the finish kit, because I have all ready paid for them.

On my airplane, the aft split part of f-1294B almost touched the stab, so I moved the top forward about 3/16". I then had to expand the spar box cutouts and the rudder horn cutout. It might have been better to slide the whole thing (top and bottom) forward. They are really nice parts.

John

UK Builder. Tail cone came witlh tailcone/empennage kit in seperate cardboard box. The original finish is good quality, does not look like a load of work to get a good finish. However, I have I have requested a copy of guru Jim Cone's paper.

Jim Devlin