rigid tubing--

Guys seem to have some issues bending their rigid lines. There have been alot of posts in the past on this, so I wont bore everyone. I guess because I do this all the time, that is easy. Heck---I had a hard time riviting--so you get my point.

Bending tubing does take practice with the bender or benders you are going to use. I have some thoughts that might help some of you.

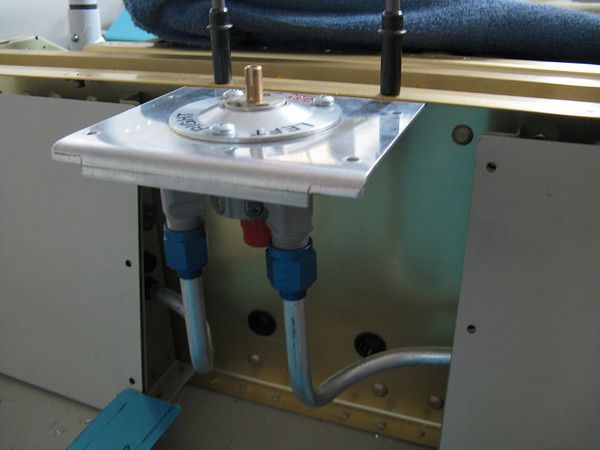

1st- get a good bender, and not a $14.95 special at brand X autoparts. The Imperial 370 and 470 benders will do anything that we need to do. 180* bends, with nice concentric radii. Unless you have a hydraulic powered mandrel bender at your disposal (if you do, let me know!), then these bender will serve you well. Avery, GAHCO, Spruce, and others have them. By some extra tubing in the sizes you will be using; for most of us thats 1/4 & 3/8.

2nd)- PRACTICE the type of bends you will be doing. I take a blue Sharpie, and make a line where I want the bend centerline to be, and then practice hitting that line. Once you do it several times, you will see where the scale on the handle lines up with your index mark. Repeat this until you can do it over and over. Then draw another line further down the tube, and make a different angle bend, oriented in a different plane. Do that until you are comfortable doing multiple angle assemblies.

3rd)- can you make a multi-angled tube that has to go over, under, around, or through something? Gee, I dont know. Try this. I use a piece of either 3/16 or 1/4 bundyflex brake tubing (the straight lengths you can get at X autoparts). You can use cooper tubing, but its getting expensive. The object is to make a pattern of the assembly you want before you ever pick up the bender. Take the tubing and make some rough bends by hand to approximate the bends and angles. ALOT easier to do this than to scap a bunch of tubing, because the angles were off. Once this pattern is done, remove it, and see if there are any limitations as to why you cant bend a real tube with your bender. (Let me say here, that I am NOT a muscle guy with hands the size of baseball gloves. So I made a bracket to put my benders in my vise, so I can use both hands to do my bending).

4th)- I may be necessary to flare your tubing before bending. If so, ok. Take your new tubing and using your pattern, make your first centerline. Bend it, using your pattern as a guide. Then, just continue to the next bend and repeat. You can even measure the centerline distances between bends if you wish, and make those bends. Having your pattern will certainly help.

This seems VERY long a drawn out, but in fact its pretty straight forward. Has worked for me for many years. And unless you have a CNC mandrel bender, with laser coordinate capabilty in your shop, it can work for you to.

I hope this helps--

Tom