wirejock

Well Known Member

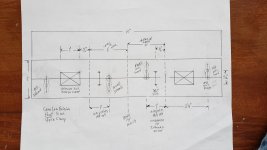

This is an alternate to the "fiberglass finger" method of clamping the Gear Leg Fairing with a breeze clamp.

This seems to work really well. Fabricate two of these. I made them mirror to each other so the outboard nut plates are higher outside on both port and starboard. I oriented the breeze clamp so the access hole to adjust it is on the inboard side. Aesthetics.

It's easier to lay it out, drill, dimple and install nutplates before bending and cutting relief holes.

Attach it snug but not tight. Drill the screw holes in the fairing and the access hole to adjust the breeze clamp. Screw the fairing to the clamp. Adjust the fairing. Tighten the breeze clamp. Easy peasy.

Edit...

The clamp works better if the lower nutplates are outboard. Drawing shows them the other way.

Reason is access from under the wing. It's pretty close as it is so lower nutplates on the outboard side are a little easier to put screws in.

Edit 04/21/2023

I uploaded the pdf to my Google Drive. If you want to download. Here's the link

Gear Leg Fairing Clamp

This seems to work really well. Fabricate two of these. I made them mirror to each other so the outboard nut plates are higher outside on both port and starboard. I oriented the breeze clamp so the access hole to adjust it is on the inboard side. Aesthetics.

It's easier to lay it out, drill, dimple and install nutplates before bending and cutting relief holes.

Attach it snug but not tight. Drill the screw holes in the fairing and the access hole to adjust the breeze clamp. Screw the fairing to the clamp. Adjust the fairing. Tighten the breeze clamp. Easy peasy.

Edit...

The clamp works better if the lower nutplates are outboard. Drawing shows them the other way.

Reason is access from under the wing. It's pretty close as it is so lower nutplates on the outboard side are a little easier to put screws in.

Edit 04/21/2023

I uploaded the pdf to my Google Drive. If you want to download. Here's the link

Gear Leg Fairing Clamp

Last edited: