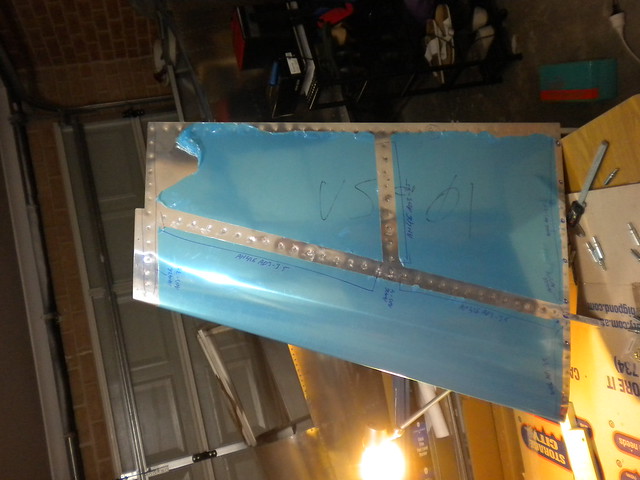

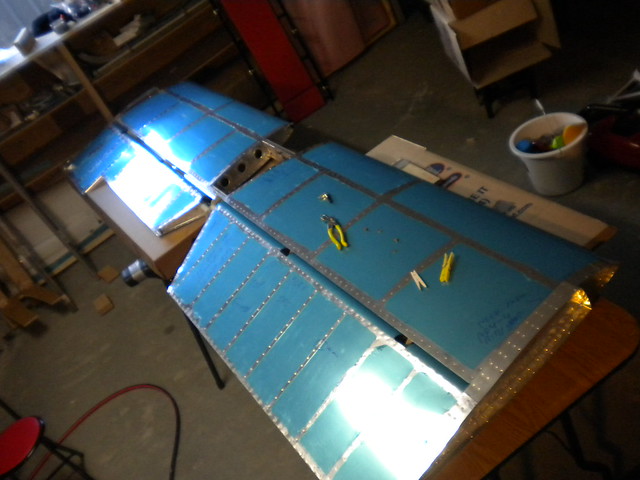

2 year update

So, it is 2-odd years since I first flew - though I lost nearly 12 months of that after getting cleaned up by a kid on a motorbike that broke my arm and leg - so I figured I might as well post a few tidbits about what I've found/learnt so far.

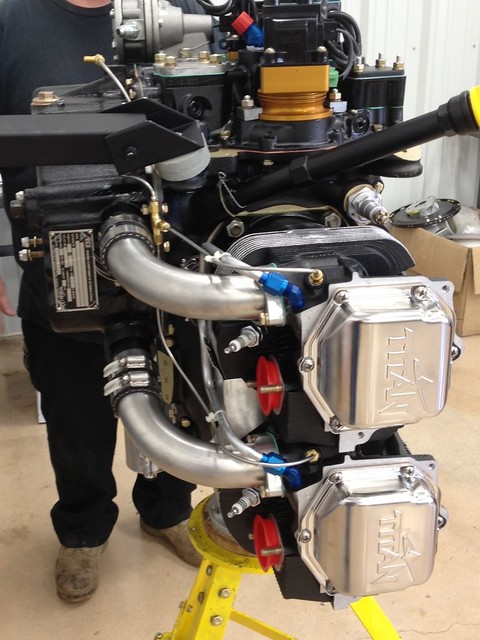

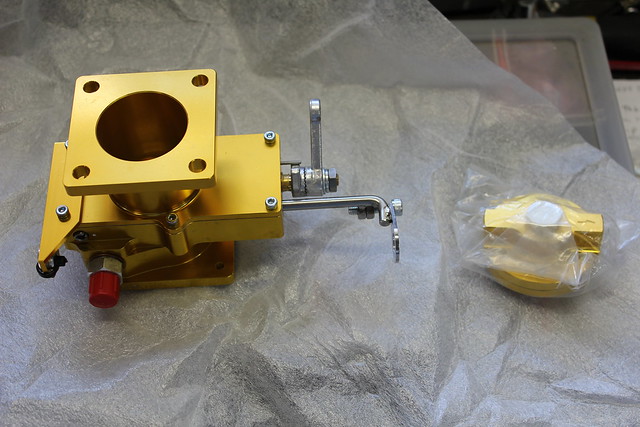

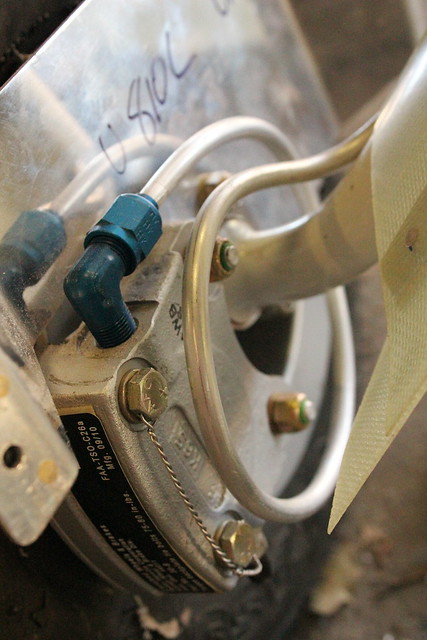

After swapping to the Mk II Rotec TBI 48/4-5 from the original Mk I, I have not suffered vapour lock since, but in saying that, I also wrapped the fuel lines FWF with exhaust wrap, and now run AvGas exclusively for takeoff and landing, so it is impossible to draw a definitive conclusion, though Avgas with the MkI did cause occasional issues on a quick-turn on a hot day too.

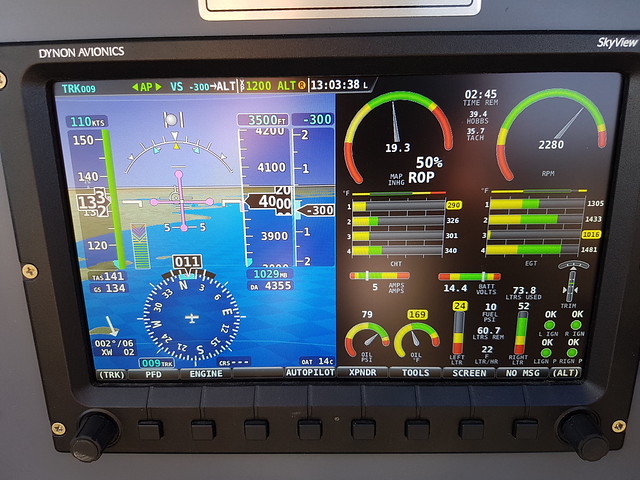

Indicated fuel flow almost doubled on installing the new TBI, and I am not sure why, as it will fluctuate from a normal 24-25LPH right up to 35-36 in the cruise. I am going to make a custom fuel line from the flow sensor to the TBI to try to eliminate the 2 x 90* bends as it exits the red cube. A 2 hour flight test showed I am still using the normal 24.5LPH though, so it isn't actually

flowing more fuel, thankfully.

Running a tank dry (intentionally, I might add), results in a brief stumble, around 5KIAS speed loss and takes around 5 seconds to come back up to cruise power after switching tanks. I am comfortable enough with this behaviour to make it a standard practice on cross-country flights now to maximise what I'll call "known" fuel available on landing, and ensuring it is all on the one tank.

I still have a pesky oil leak somewhere, but it certainly isn't safety-critical, just annoying. Oil stabilises a smidgen under 6Qts. Anything other than that and it spits it out the breather tube. Oil use between the few changes so far is negligible.

After a bit of back-and-forth with the lads at OzRunways (Aussie version of Foreflight, etc), we were able to get the old Ipad 2 to wifi the flight plan to the SkyView system and it accepts it with no problems whatsoever. A brilliant setup.

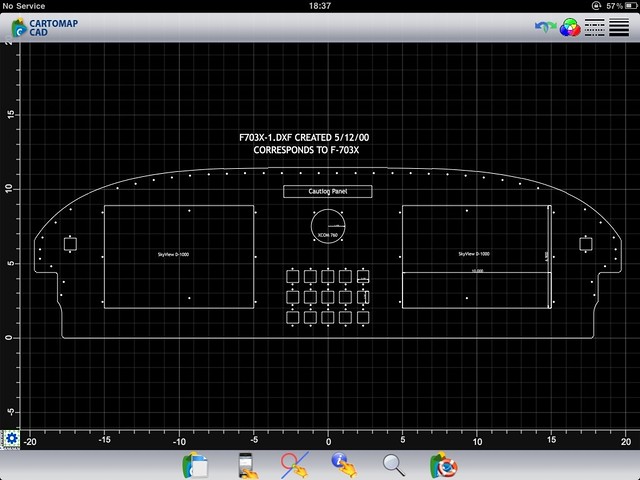

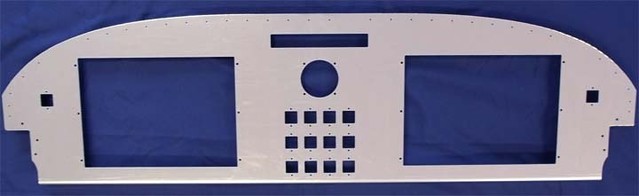

BillM at UpNorthAviation keeps all the old CAD files for his customers panels - so when I wanted to redo my panel to accomodate the Carling V switches and couldn't find my version, he emailed the original in a matter of hours, and still has very reasonable prices for his work. Still a pleasure to work with.

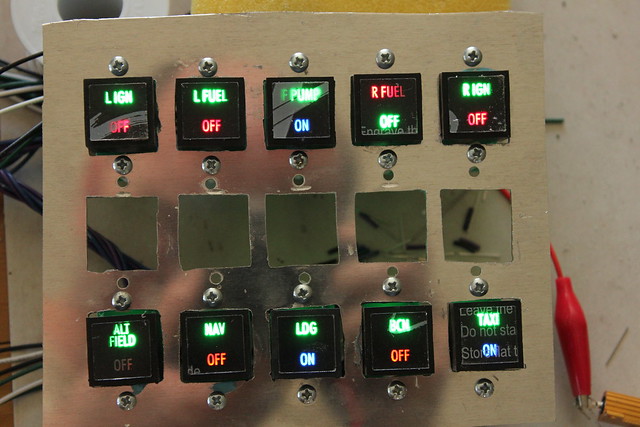

On those Carling V switches - I ordered them, with custom actuators from the folks at RockerSwitchPros, with most being

V1D1-GXXB. Decent price, fast shipping,

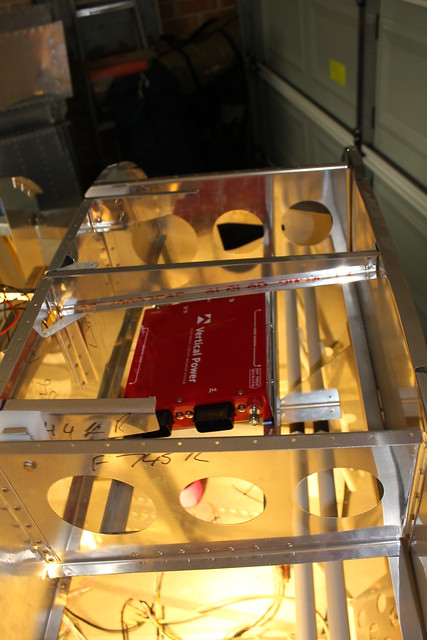

BUT - and it is a very BIIIG 'but' - I assumed that as the 'dependent' LED was at the bottom, that they would be "Up for off, down for on". This is not the case. These switches are "Down for off, UP for on", so my dependent lettering saying "ON" when pressed actually turns them off. Also - it turns out these switches are designed to be inserted between a supply and a load. I am using these switches to control my VP-X, that then controls the load. The problem with this setup is the dependent LED's

do not work at all, as there is no current flowing through the switch. If you want to use the bottom LED as an indicator of circuit status, these need to be between the VP-X and your device with that power pin set to 'always on',

or you need to buy a switch that has two independent LED's and tap into the positive lead from the VP-X to also illuminate your switch. It isn't a huge problem, just means I have to re-order the switch actuators with "OFF" as the bottom text.

As regards the instrument panel: Have a look on plans, page 24A, where the throttle sub-pane mounting screw insert is. See how they are off-set from the actual throttle/mixture control holes? Guess which muppet missed

that little tidbit in the plans, and then had to remove the throttle cable to remove the sub-panel?!? I finally remedied that a couple of days ago when installing the new panel.

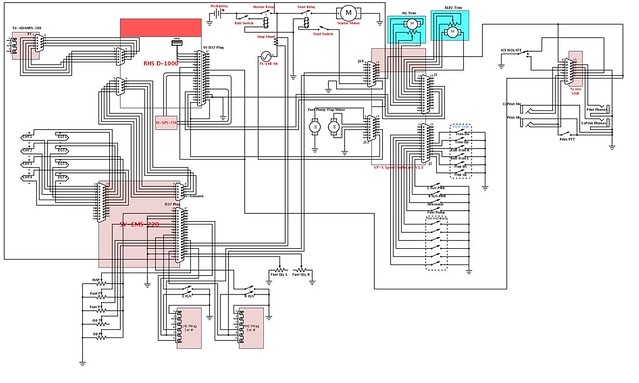

I have installed a KLN-90B old-school IFR GPS as under Australian rules, this pushes the 'time for a positive position fix' for VFR pilots out from 30 minutes to 2 hours, and an approved RNAV system (such as the KLN)

counts as a positive fix. It talks to SkyView using the ARINC-429 module, and it will display the flight-plan on the SkyView map page too. But, because SkyView does not transmit ARINC labels 306 and 307, you cannot

send waypoints from SkyView to the KLN, unfortunately.

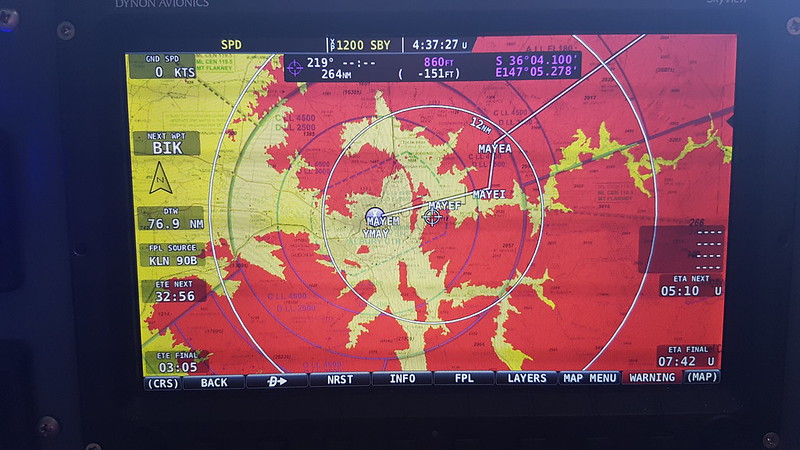

Here's a demo showing the GPS RNAV approach into Albury. Lots of red as I am still on the ground miles away.

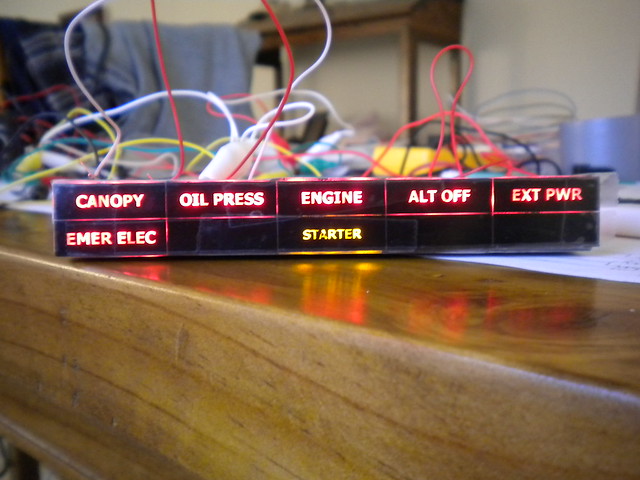

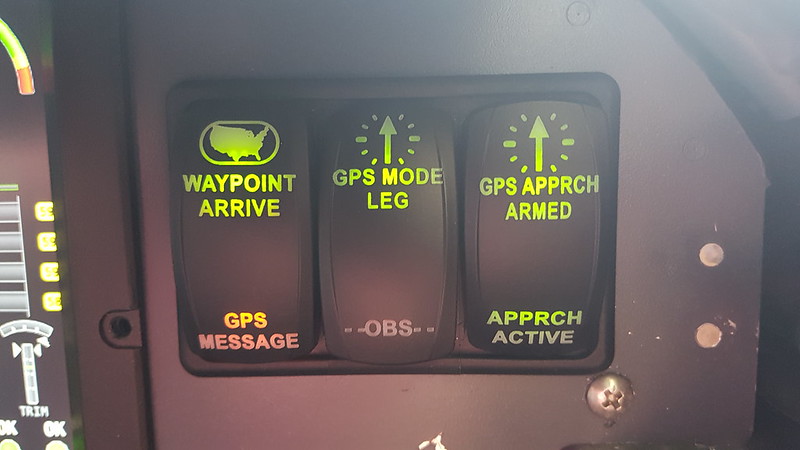

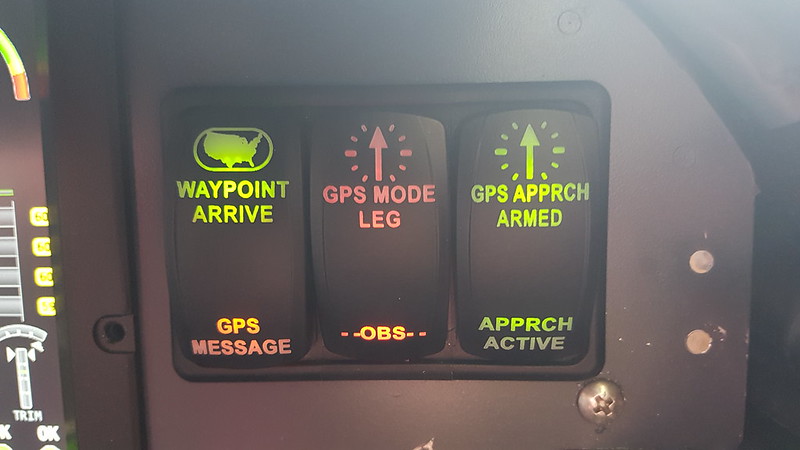

Because I couldn't justify the cost of a Mid-Continent annunciator panel (and couldn't seem to get lucky with a12V unit on eBay), I decided to DIY an annunciator panel for the KLN, using Carling V switches and some custom actuators, again from the folk at RockerSwitchPros. And they turned out rather nicely too, I think...

And with "OBS" mode selected:

The new panel - very similar to the old one, but with the Carling switches, and the GPS annunciators (and yes, they are mirrord on both sides. Why? Because I can, and it'll give Mini-Me something to play with enroute. His switch contacts are not connected.)

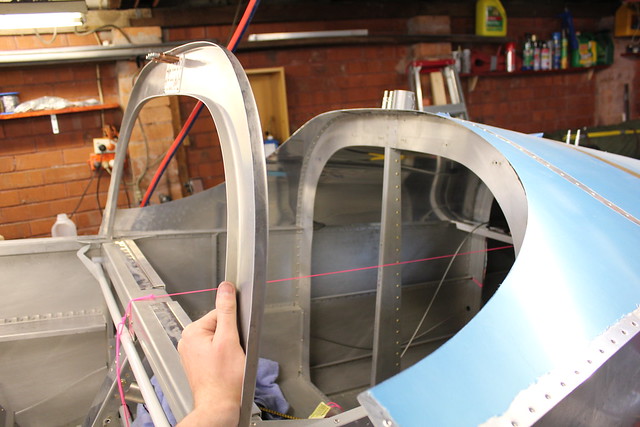

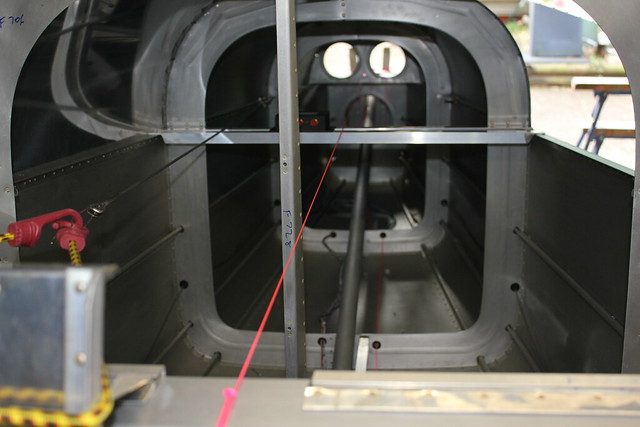

I couldn't justify the cost of a set of Classic Aero seats, nice as they may be, so after measuring the KRviatrix's Suzuki Swift, I figured those seats would likely fit. And they do! Quite well, in fact. I needed to trim a small wedge of foam from the outboard shoulder to clear the aft canopy frame, but that is masked by the seat fabric, and I cut out a 6x6x6" cube for stick movement, but they do fit (almost pefrectly over the Vans aluminium seat back, are surprisingly lightweight when you remove the steel frames, and are amazingly comfortable, probably due to the bucket-style. And they have headrests, though I should have straightened up the coey's one before I took this photo...

Following on from the above photo, that yellow thing in the background is a

Rescue Swag, an all-purpose first-aid kit in a heavy duty roll-out yellow vinyl wrapper. It's clipped onto two eye-bolts sourced from the aviation aisle at the local Bunnings, with the platenuts tapped to match the threads. IT isn't quick-and-easy to get to, but anything extremely serious is likely to be beyond its' capabilities anyway.

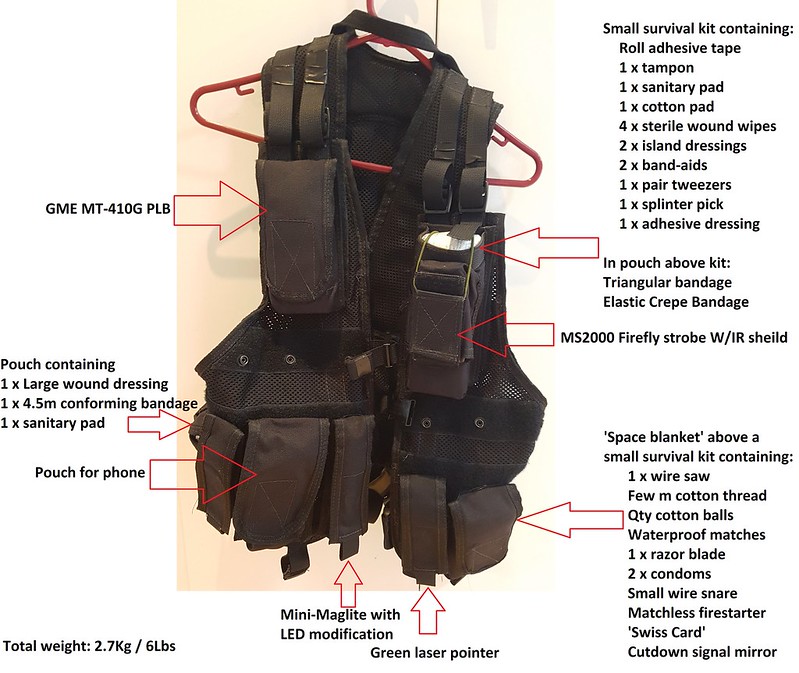

And as the Rescue Swag may either go down with the plane if I ditch, or burn if I crash, I now fly wearing a survival vest containing some personal 'must-haves' that cover the basics and will hopefully keep me alive until rescued. I don't kid myself that flying is "safe". Let's face it, I built a plane

in my back shed...I don't view flying as particularly

unsafe, but things can, and do, go wrong, and I'd like to swing the odds in my favour wherever I can. While wearing this vest, you can still fit in the seat reasonably comfortably, and can also comfortably wear a (manually) inflatable life vest as well if needed. Some of my flying involves

low-level over-water legs where you would certainly get wet if you had an engine failure.

Some of the items in the vest, and their reasons for being there are described below:

- PLB: A GME MT-410G, A 406 PLB with the -G model having GPS functionality built-in. It also has a 7-year battery life, and, in accordance with CAsA requirements, is registered to me such that if I do set it off, AMSA can call a list of pre-supplied contacts, and if they determine it is a genuine activation, I've even uploaded a photo of the -9 to their database so they know what they're looking for. A great idea from the Government, surprisingly...

- Firefly Strobe. I got it from my ADF days and figured I can finally put it to use. IR probably isn't as useful in civilian life as I don't think any of our EMS helicopters use NVG's 'yet'.

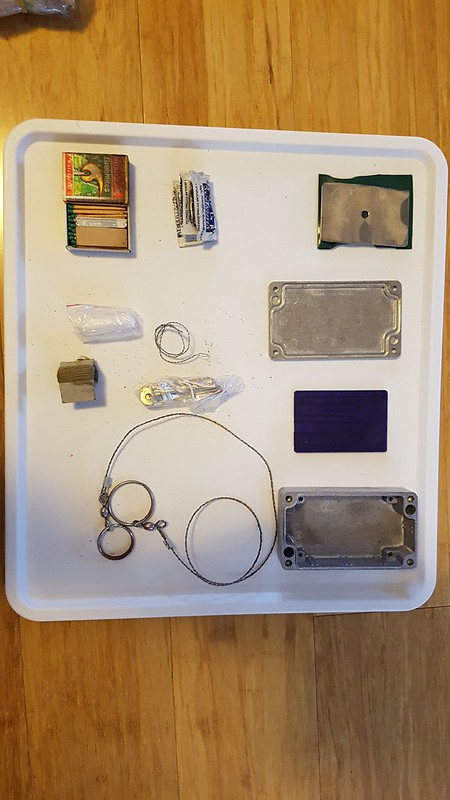

- Survival kit: Signal mirror to try to attract attention in daylight. Space blanket for shelter & keeping warm at night. Matches, firestarter & cotton balls to try to get a fire going if stranded overnight. Wire saw to cut small branches for shelter if needed. Condoms to store/carry water if needed - 2L if used in one of my socks. Swiss card as a small knife, scissors, pen, toothpick & small file in a credit-card sized footprint.

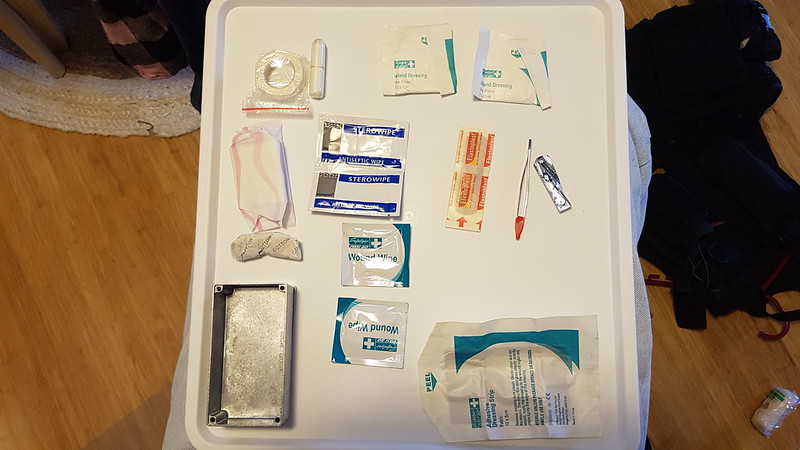

- First-aid kit: The essentials to stem a major bleed if I don't have the rescue swag. Tampon & sanitary pad as they are small, already sterile, and quite absorbent. Dressings and tape to cover the wound/s. Triangular & crepe bandages in case I break something & need to splint it.

- Mini-Maglite: Swapped from the regular globe to LED to conserve the batteries if needed. And on that, the batteries in the Maglite and the laser pointer are both positive-to-positive to prevent inadvertent activation and are long-life lithium batteries.

- Green Laser pointer: Can be seen for miles at night, even without directly aimed at an aircraft.

The survival & first aid kits themselves are housed in small tins sourced from the local electronic retailer designed to house small PCB's.

Contents of the first aid kit, from the upper left pocket:

And contents of the survival kit, from the left hip pouch:

As above -you learn from your mistakes.

As above -you learn from your mistakes.