SmittysRV

Well Known Member

Hi Guys,

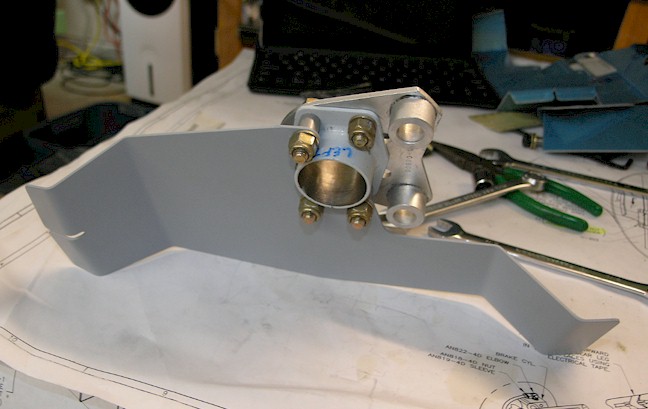

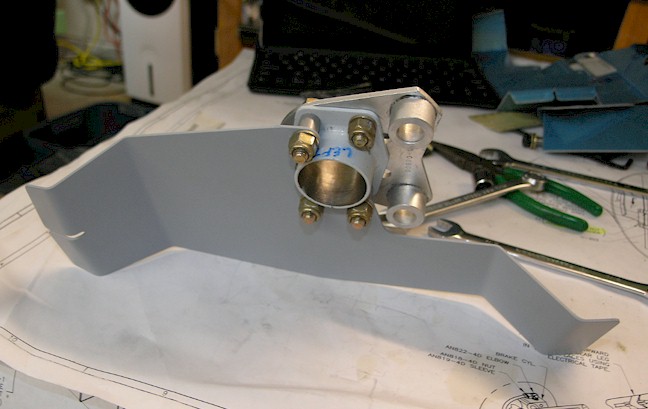

I have finished the first part of the gear/brake assembly (left gear shown below). My question is whether the brake mounting plate is on right. I couldn't tell by the drawings which way it went on. From the pictures I seen from other builders websites, it looked like this was the correct setup. What do you think? Thanks in advance!

I have finished the first part of the gear/brake assembly (left gear shown below). My question is whether the brake mounting plate is on right. I couldn't tell by the drawings which way it went on. From the pictures I seen from other builders websites, it looked like this was the correct setup. What do you think? Thanks in advance!