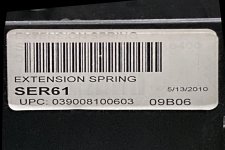

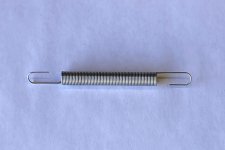

I have been chasing carb balance, trying to get a perfect balance at 3500 and also 1750. I could get one or the other but not both. I settled for 3500 balanced and then at 1750 they would be off unless I pulled hard on the throttle cable. I found the left carb was not hitting the idle stop unless I pulled hard. Once on the stop they were in balance. Chasing down the issue i found the left cable has the slightest bit more drag than the right so the right made it to the stop and the left was stopping .040 short of the stop, enough to keep them out of balance. My carbs have the coil return springs. For a test I added the expansion springs in addition to the coil and the carbs now run in perfect balance regardless of RPM. I can tighten the friction to eliminate most all of the creep. I know this setup isn't ideal but is loads the cables and keeps them traveling equally.

Has anyone else seen this or has a better idea?

Has anyone else seen this or has a better idea?