cjensen

Well Known Member

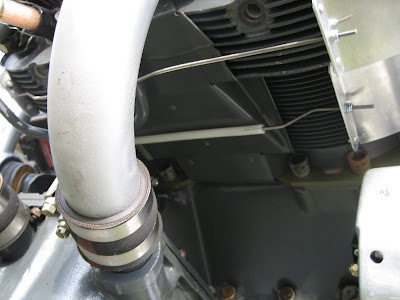

How is everyone getting the steel tie rods for the under cylinder baffles threaded???

I've got mine cut to length, and was trying to thread the first one today...busted it. The rod twists, work hardens, and SNAP! Yes, I am using lube, and the correct 6-32 thread nut...so now I have to find at least one more piece of rod to replace the one I broke, and now I'm afraid to do the rest!

How did you do it?

I've got mine cut to length, and was trying to thread the first one today...busted it. The rod twists, work hardens, and SNAP! Yes, I am using lube, and the correct 6-32 thread nut...so now I have to find at least one more piece of rod to replace the one I broke, and now I'm afraid to do the rest!

How did you do it?