Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cowling fasteners - stray from plans?

- Thread starter rsr3

- Start date

I used the Milspec brand of cam locks rather than hinges for many reasons.

they are adjustable for material thickness (different parts of the cowl edges have varying thickness),

Piano hinges eyelets often break requiring a new hinge to be riveted on which damages paint. Cam lock style are easily replaced but probably won’t need to be.

Cam locks allow quick and easy cowl removal/install. Similar to hinges.

Cam locks are more than hinges visible but I like the look. I don’t like the look of hinges.

Maybe it boils down to personal preference. But I really don’t want to be replacing a section of hinge.

Bevan

they are adjustable for material thickness (different parts of the cowl edges have varying thickness),

Piano hinges eyelets often break requiring a new hinge to be riveted on which damages paint. Cam lock style are easily replaced but probably won’t need to be.

Cam locks allow quick and easy cowl removal/install. Similar to hinges.

Cam locks are more than hinges visible but I like the look. I don’t like the look of hinges.

Maybe it boils down to personal preference. But I really don’t want to be replacing a section of hinge.

Bevan

I am still a bit undecided on if I would use them again but that isnt your question.

If you want to use the skybolts, consider not purchasing their chain saw type receptables. They took much longer to install and act like a chain saw when putting the cowling back on. Using a strip of aluminum would make installing easier and getting things drilled more precise.

Good luck with them and make sure you consider spacing carefully especially at the top-bottom joint at the firewall.

If you want to use the skybolts, consider not purchasing their chain saw type receptables. They took much longer to install and act like a chain saw when putting the cowling back on. Using a strip of aluminum would make installing easier and getting things drilled more precise.

Good luck with them and make sure you consider spacing carefully especially at the top-bottom joint at the firewall.

I found that hinges work great for the sides, both vertical and horizontal.

I used screws across the top, bottom and each side of the spinner. The top because of ease of cowling installation and across the bottom because the hinges kept breaking.

After flying for over 25 years they all still look great and I would do it the same way today.

I used screws across the top, bottom and each side of the spinner. The top because of ease of cowling installation and across the bottom because the hinges kept breaking.

After flying for over 25 years they all still look great and I would do it the same way today.

Last edited:

Southern Pete

Well Known Member

If you deviate from the plans it will take significantly longer.

+1 for hinges on the straight bits.

I have found the hinges on the back of the top cowl and the underneath of the bottom cowl to be difficult to live with and have recently converted to skybolts, see first statement! Cowling installation and removal is much easier.

+1 for hinges on the straight bits.

I have found the hinges on the back of the top cowl and the underneath of the bottom cowl to be difficult to live with and have recently converted to skybolts, see first statement! Cowling installation and removal is much easier.

Opinions are like Cowboy hats....

https://vansairforce.net/community/showthread.php?t=207879

There's probably enough opinions in the attached link to weight what you want to do. Hey, 2.6% thought it a dumb question.

https://vansairforce.net/community/showthread.php?t=207879

There's probably enough opinions in the attached link to weight what you want to do. Hey, 2.6% thought it a dumb question.

I found that hinges work great for the sides, both vertical and horizontal.

I used screws across the top, bottom and each side of the spinner. The top because of ease of cowling installation and across the bottom because the hinges kept breaking.

After flying for over 25 years they all still look great and I would do it the same way today.

Same here and don't regret the decision.

Larry

D-Dubya

Well Known Member

One thing I haven't seen mentioned yet was that the internal hinge pins are not comfortable to remove when the engine and everything inside the cowling is hot. Reaching your arm up inside the oil door on a hot engine can bring on involuntary vocabulary outbursts.

Early in my build, I had an experienced builder tell me that you have to be thinking about maintenance and easy access when you're actually flying this thing. He put quarter-turn fasteners (a.k.a. cam-locks) along the aft edge of the top cowling and hinges that can be accessed externally on the side seams. After you have top off, access to rest is easy. The underside of the bottom cowling aft edge also had quarter-turn fasteners. I did the same and haven't regretted it.

Early in my build, I had an experienced builder tell me that you have to be thinking about maintenance and easy access when you're actually flying this thing. He put quarter-turn fasteners (a.k.a. cam-locks) along the aft edge of the top cowling and hinges that can be accessed externally on the side seams. After you have top off, access to rest is easy. The underside of the bottom cowling aft edge also had quarter-turn fasteners. I did the same and haven't regretted it.

Our three RV’s have every combination imaginable - hinges, screws, and Skybolts (actually MilSpec) - in all locations. And. They all work! I can’t say that I’d “never use any of the methods” but my favorite combination is probably hinge pins on the sides and rear of the lower coal, with Skybolts across the top. But I can get the R-6 cowl (all screws except hinge pins on the rear of th lower cowl) off in about three minutes - so its all good…..

Bonanzatom

Member

Converting from piano hinge to SkyBolts on RV7

Since we are discussing the pros and cons, I would like to convert the piano hinge along the aft top of the cowl to SkyBolts. What is the process and how difficult and time consuming is it?

Since we are discussing the pros and cons, I would like to convert the piano hinge along the aft top of the cowl to SkyBolts. What is the process and how difficult and time consuming is it?

wirejock

Well Known Member

Hinge removal

Installing Skybolts is no problem.

Removing the hinge may take some time.

Since we are discussing the pros and cons, I would like to convert the piano hinge along the aft top of the cowl to SkyBolts. What is the process and how difficult and time consuming is it?

Installing Skybolts is no problem.

Removing the hinge may take some time.

dmattmul

Well Known Member

Boelube

I can see individuals during the build stage making individual choices but when I see someone wanting to take most likely days (weeks) to modify their current fasteners then if painted even more of a PITA I wonder how bad the issue could be. I have hinge pins all around and love the look and ease to take cowling on and off. I even have a 3 bladed prop. I do know if you don’t use Boelube wax EVERY time they are a pain but other than that they install and remove very quickly and better yet the clean look is great. I do admit that if the engine is hot and you do need to remove the top aft hinge pins a little troublesome but wait 15 mins and no problem. I did remove them once after a 5 minute shutdown and that was a little hot but not the end of the world. How often do you need to remove them after a very short time ? During install I find the hinge pins a help to “ladder” up each side 3 hinge pins at a time each time inserting the pin to hold it while I go to the others side. By the way I’m not young but getting inside still not really a problem. Can someone define the exact issue with hinge pins ?

I can see individuals during the build stage making individual choices but when I see someone wanting to take most likely days (weeks) to modify their current fasteners then if painted even more of a PITA I wonder how bad the issue could be. I have hinge pins all around and love the look and ease to take cowling on and off. I even have a 3 bladed prop. I do know if you don’t use Boelube wax EVERY time they are a pain but other than that they install and remove very quickly and better yet the clean look is great. I do admit that if the engine is hot and you do need to remove the top aft hinge pins a little troublesome but wait 15 mins and no problem. I did remove them once after a 5 minute shutdown and that was a little hot but not the end of the world. How often do you need to remove them after a very short time ? During install I find the hinge pins a help to “ladder” up each side 3 hinge pins at a time each time inserting the pin to hold it while I go to the others side. By the way I’m not young but getting inside still not really a problem. Can someone define the exact issue with hinge pins ?

I use hinges over the top, the longitudinal and vertical sides. I used the Skybolt blind fasteners at the bottom because the hinge access is problematic at the bottom with the muffler getting in the way.

For the top hinge, I cut a small access hatch directly at the centerline on the top of the cowl after finding my friend's RV8A top hinge removal was somewhat difficult digging inside the oil cover door. The only person to see the access hatch is the pilot when sitting in the cockpit. The hatch is out of view from the ground perspective.

For the top hinge, I cut a small access hatch directly at the centerline on the top of the cowl after finding my friend's RV8A top hinge removal was somewhat difficult digging inside the oil cover door. The only person to see the access hatch is the pilot when sitting in the cockpit. The hatch is out of view from the ground perspective.

RV7Guy

Well Known Member

Skybolts!!

I used Skybolt on both of my 7's. Absolutely no issues and would do it again. I even used them on the wheel pants. 5 minutes on and off to remove the front of the pant to check tire pressure.

Skybolts are the real deal. Made in America and not a knock off like the other brand.

I used Skybolt on both of my 7's. Absolutely no issues and would do it again. I even used them on the wheel pants. 5 minutes on and off to remove the front of the pant to check tire pressure.

Skybolts are the real deal. Made in America and not a knock off like the other brand.

UnPossible

Well Known Member

On both my 7A and my 10, I used the hinges along the sides of the cowl, but on the my first plane (7A) I used Skybolts around the firewall..... and I didn't really like them.

I didn't like how the Skybolts hung down below the cowl, so that every time you put the top cowl back on, you risked scratching the forward fuselage paint. I also had a few that the retainer clips would not hold in over time.

On my more recent 10 build, I just used #8 screws, tinnerman washers and nutplates. Instead of $500 in Skybolts, I have about $20 in fastener costs. With a powered screw driver, it takes maybe a couple of minutes longer to get the cowl off, but there is nothing hanging down to scratch the paint.

After building a plane with both methods, I think I would use the screws and nutplates on any future builds.

I didn't like how the Skybolts hung down below the cowl, so that every time you put the top cowl back on, you risked scratching the forward fuselage paint. I also had a few that the retainer clips would not hold in over time.

On my more recent 10 build, I just used #8 screws, tinnerman washers and nutplates. Instead of $500 in Skybolts, I have about $20 in fastener costs. With a powered screw driver, it takes maybe a couple of minutes longer to get the cowl off, but there is nothing hanging down to scratch the paint.

After building a plane with both methods, I think I would use the screws and nutplates on any future builds.

Kyle Boatright

Well Known Member

After building a plane with both methods, I think I would use the screws and nutplates on any future builds.

Same here. The -6 has screws across the top of the cowl and the -10 has MilSpec quarter turns. Airplane #3 would go back to the screws.

Skybolt/Screws

On my 8 I have all skybolts. I'm building another 8 at the moment and will use skybolts again - but - what I am going to do differently... The first few skybolts near the front will be replaced with screws. It is really a pain to get the tight curve on the 8 cowl to nest since the skybolts stick out a bit. So maybe the first three skybolts will be replaced with screws to make it easier to get the top cowl on.

YMMV

Dave

On my 8 I have all skybolts. I'm building another 8 at the moment and will use skybolts again - but - what I am going to do differently... The first few skybolts near the front will be replaced with screws. It is really a pain to get the tight curve on the 8 cowl to nest since the skybolts stick out a bit. So maybe the first three skybolts will be replaced with screws to make it easier to get the top cowl on.

YMMV

Dave

Improvement

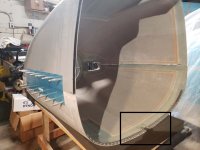

OK so why would a builder spend additional time/ money on a part of the build?

For me it was if I could improve looks, performance or future maintenance.

I looked at what others were doing and came to a couple of conclusions.

I don't like the looks of the Skybolts. I like the clean look of the hinges. I even used hinges on the wing tips.

What is wrong with or what can be improved with the hinge method.

Air leaks - I added a small plate at the top corners of each side to reduce the air leakage through the gap.

Top of cowl movement when pressurized.

Difficulty of getting to, removing and installing hinge pins for the top.

Both of these were solved by installing equal length hinges on the top and cutting a small trapezoidal hole on the top of the cowl. Mounting a bracket to the top firewall with holes for the hinge pins. A small Trapezoidal plate screwed to the bracket to keep the pins in place and hold the cowl down. This also allowed the use of the proper size pin rather than a smaller diameter pin to get around the corners. Easy to remove and no play in the cowl top.

Also used plates with screws along both bottom sides.

[/IMG]

[/IMG]

OK so why would a builder spend additional time/ money on a part of the build?

For me it was if I could improve looks, performance or future maintenance.

I looked at what others were doing and came to a couple of conclusions.

I don't like the looks of the Skybolts. I like the clean look of the hinges. I even used hinges on the wing tips.

What is wrong with or what can be improved with the hinge method.

Air leaks - I added a small plate at the top corners of each side to reduce the air leakage through the gap.

Top of cowl movement when pressurized.

Difficulty of getting to, removing and installing hinge pins for the top.

Both of these were solved by installing equal length hinges on the top and cutting a small trapezoidal hole on the top of the cowl. Mounting a bracket to the top firewall with holes for the hinge pins. A small Trapezoidal plate screwed to the bracket to keep the pins in place and hold the cowl down. This also allowed the use of the proper size pin rather than a smaller diameter pin to get around the corners. Easy to remove and no play in the cowl top.

Also used plates with screws along both bottom sides.

M5fly

Well Known Member

One thing I haven't seen mentioned yet was that the internal hinge pins are not comfortable to remove when the engine and everything inside the cowling is hot. Reaching your arm up inside the oil door on a hot engine can bring on involuntary vocabulary outbursts.

Early in my build, I had an experienced builder tell me that you have to be thinking about maintenance and easy access when you're actually flying this thing. He put quarter-turn fasteners (a.k.a. cam-locks) along the aft edge of the top cowling and hinges that can be accessed externally on the side seams. After you have top off, access to rest is easy. The underside of the bottom cowling aft edge also had quarter-turn fasteners. I did the same and haven't regretted it.

This is a rather underrated comment. I was always so frustrated having to remove these pins when the engine was hot. If I didn't have on gloves and a long sleeve sweatshirt I'd have some nice burns! I'm honestly surprised more people don't complain about this.

OK so why would a builder spend additional time/ money on a part of the build?

For me it was if I could improve looks, performance or future maintenance.

I looked at what others were doing and came to a couple of conclusions.

I don't like the looks of the Skybolts. I like the clean look of the hinges. I even used hinges on the wing tips.

What is wrong with or what can be improved with the hinge method.

Air leaks - I added a small plate at the top corners of each side to reduce the air leakage through the gap.

Top of cowl movement when pressurized.

Difficulty of getting to, removing and installing hinge pins for the top.

Both of these were solved by installing equal length hinges on the top and cutting a small trapezoidal hole on the top of the cowl. Mounting a bracket to the top firewall with holes for the hinge pins. A small Trapezoidal plate screwed to the bracket to keep the pins in place and hold the cowl down. This also allowed the use of the proper size pin rather than a smaller diameter pin to get around the corners. Easy to remove and no play in the cowl top.

Also used plates with screws along both bottom sides.

[/IMG]

This was how I did mine. No reaching inside the hot engine compartment to remove the pins.

Mark or Phat - would you be able to share a picture of how you access the pins when your top cowling is on, please?

Thanks!

The upside down picture shows the interior of the hinge with the cut-out while I was building it. The painted exterior picture shows the plate that covers the cut-out hole. The cover plate is 0.032 scrap aluminum.

Attachments

Richard Connell

Well Known Member

This is a rather underrated comment. I was always so frustrated having to remove these pins when the engine was hot. If I didn't have on gloves and a long sleeve sweatshirt I'd have some nice burns! I'm honestly surprised more people don't complain about this.

This just wasn't my experience with the RV7. Sure if you tried to pull them as the prop was still spinning down maybe, but leave it just a few mins and they fine. They have too little mass to stay hot for long. 10y like that. no issues.

The only PITA hinges on the 7 were the ones along the bottom. Exhaust, oil, vibration etc. I replaced them with screws.

FWIW Im a hinge all round guy. I think its neater, tighter and quicker. But each to their own. I have a showplanes cowl on my RV10, so I do have 8 MilSpecs on the bottom attach to the gear shock fairing.

Both RVs had the horizontal pins installed from the cabin side.

Another example of something that works really well, but everyone who hasn't done it tells me I'm crazy...just another technique to learn.

My top pins have a small plate not too dissimilar to Phats. Im still refining that. Its small. I may enlarge it pre paint. Need to stop the pins rubbing the outside surface on removal/insertion.

dmattmul

Well Known Member

Polished hinge pins

After 3 years my top cowl hinge pins where getting a little “sticky” even though I Boelube them almost every time. I decided to polish them with (below) and after doing this they slid in like buttered. I did get a lot of oxidation off when I did this. Highly recommend.

After 3 years my top cowl hinge pins where getting a little “sticky” even though I Boelube them almost every time. I decided to polish them with (below) and after doing this they slid in like buttered. I did get a lot of oxidation off when I did this. Highly recommend.

Attachments

On both my 7A and my 10, I used the hinges along the sides of the cowl, but on the my first plane (7A) I used Skybolts around the firewall..... and I didn't really like them.

I didn't like how the Skybolts hung down below the cowl, so that every time you put the top cowl back on, you risked scratching the forward fuselage paint. I also had a few that the retainer clips would not hold in over time.

On my more recent 10 build, I just used #8 screws, tinnerman washers and nutplates. Instead of $500 in Skybolts, I have about $20 in fastener costs. With a powered screw driver, it takes maybe a couple of minutes longer to get the cowl off, but there is nothing hanging down to scratch the paint.

After building a plane with both methods, I think I would use the screws and nutplates on any future builds.

While I have screws top and bottom on the 6 with 0 regrets, I made the 10 per plans (used SS hinges on bottom though) and I really like it. The 10 has the hinge pins ends outside and that is nice, as I never liked the idea of having them buried inside the cowl. Also no regrets on the 10.

Larry

After 3 years my top cowl hinge pins where getting a little “sticky” even though I Boelube them almost every time. I decided to polish them with (below) and after doing this they slid in like buttered. I did get a lot of oxidation off when I did this. Highly recommend.

That is a GREAT idea. Mine are a bit of a pain to get out or in when cold.

Larry

Draker

Well Known Member

I went with hinges, but I think it's entirely personal preference. Vans has you use screws on the bottom edge of the -7A lower cowl now. I think this changed with the new elastomer nosegear. They are a total pain. No matter how gently I screw them in, I end up stripping the philips heads when unscrewing. I need to start flying and stop modding, but one of the things I plan to do post phase 1 is to figure out a better attachment for the lower cowl.

Screws and Hinges

I went with #8 stainless screws all around the cowl/firewall perimeter. The anchors are K1000-08s mounted under a 2" wide x .032" flange. A little Boelube (wax) on each screw keeps them from galling/stripping.

I am using small flange finish washers (39006F) under each #8 screw -- this protects the fiberglass from wearing through and has a nice clean look.

MS20001-P3 & P4 hinge material for the cowl sides. The difference in hinge widths allows the hinge to be offset to hide the hinge eyes and maintain edge distance.

I went with #8 stainless screws all around the cowl/firewall perimeter. The anchors are K1000-08s mounted under a 2" wide x .032" flange. A little Boelube (wax) on each screw keeps them from galling/stripping.

I am using small flange finish washers (39006F) under each #8 screw -- this protects the fiberglass from wearing through and has a nice clean look.

MS20001-P3 & P4 hinge material for the cowl sides. The difference in hinge widths allows the hinge to be offset to hide the hinge eyes and maintain edge distance.