Hello, I am diagnosing a rough running / bad mag drop issue on my RV12. I t runs very rough when revving to 4000 for the mag test. It will smooth out after running higher rpm for a minute like the plugs are loading up. It is always ignition A that is rough. Does anyone have the diagram that shows exactly which spark plug locations are connected to ignition A so I can replace those plugs and take a look. I have already replaced the carb floats with no notable difference. Thanks in advance for the help.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

912uls Spark Plug Diagram

- Thread starter trecool44

- Start date

Have a look at the Rotax Heavy Maintenance Manual section 74-00-00 ... page 19 shows the trigger coil assignments. (Not at the airport, but my reference is from revision 5, so the page reference may be off a page or two in a newer manual).

You will find the complete wiring diagram in section 74-00-00 page 25.

Per the manual:

Trigger coil assignment (on the 912 Series)

Trigger coil A1/2 serves the top spark plug of cylinder 1 and 2

Trigger coil A3/4 serves the bottom spark plug of cylinder 3 and 4.

Trigger coil B1/2 serves the bottom spark plug of cylinder 1 and 2

Trigger coil B3/4 serves the top spark plug of cylinder 3 and 4.

Hope that helps.

You will find the complete wiring diagram in section 74-00-00 page 25.

Per the manual:

Trigger coil assignment (on the 912 Series)

Trigger coil A1/2 serves the top spark plug of cylinder 1 and 2

Trigger coil A3/4 serves the bottom spark plug of cylinder 3 and 4.

Trigger coil B1/2 serves the bottom spark plug of cylinder 1 and 2

Trigger coil B3/4 serves the top spark plug of cylinder 3 and 4.

Hope that helps.

Last edited:

Piper J3

Well Known Member

I would not discount carbs. Your problem does not sound like ignition or plugs.

Next time you fly - do an in-flight ignition check by cycling each ignition at cruise RPM.

Another thought... if you have completed the torsion spring upgrade for the throttle arms, then add back the original extension spring. Many folks (me included) notice smoother operation in mid-range RPM. 2nd spring adds more tension to make cable pull(s) more uniform.

Next time you fly - do an in-flight ignition check by cycling each ignition at cruise RPM.

Another thought... if you have completed the torsion spring upgrade for the throttle arms, then add back the original extension spring. Many folks (me included) notice smoother operation in mid-range RPM. 2nd spring adds more tension to make cable pull(s) more uniform.

Last edited:

NinerBikes

Well Known Member

Check the coil pack mount brackets first to see if any of them are now broken. Pull the air filters, probably clean them too, while you have them off and re oil, and inspect those funky "L" brackets that hold the coils in place.

If they are broken, the coils can rub on the engine mount and rub through and short out the coils windings. If they are broken, it's highly possible you have a vibration problem that caused them to fail. Balance the carbs, balance the prop, and verify the Clutch, Dogs, and Bellvue torque washers are in spec and not worn on the gearbox, causing vibration problems that break those brackets. On a Rotax 912ULS... not balancing causes a lot of failures of components, you have to stay on top of it and keep things in proper adjustment. The motor running a 11.0 :1 compression ratio is pretty violent if the engine RPMS are too low, making things speed up and slow down, lack of rpms creates lack of momentum, so speed things up a little bit.

Always have the owner idle the engine at somewhere very smooth running between 2000 and 2500 rpms on start up through warm up.

Always a good place to look, do a search on broken coil mounts here in the RV-12 section of VAF.

If they are broken, the coils can rub on the engine mount and rub through and short out the coils windings. If they are broken, it's highly possible you have a vibration problem that caused them to fail. Balance the carbs, balance the prop, and verify the Clutch, Dogs, and Bellvue torque washers are in spec and not worn on the gearbox, causing vibration problems that break those brackets. On a Rotax 912ULS... not balancing causes a lot of failures of components, you have to stay on top of it and keep things in proper adjustment. The motor running a 11.0 :1 compression ratio is pretty violent if the engine RPMS are too low, making things speed up and slow down, lack of rpms creates lack of momentum, so speed things up a little bit.

Always have the owner idle the engine at somewhere very smooth running between 2000 and 2500 rpms on start up through warm up.

Always a good place to look, do a search on broken coil mounts here in the RV-12 section of VAF.

Last edited:

Cammie Patch

Active Member

Before you assume the ignition system is the problem on an unusual mag drop, make sure it's not a mixture issue.

To check this, do your normal mag check, they pull the choke out about halfway, and do another mag check like that. If the results are different, it's your carbs not your ignition.

4000 RPM is the leanest range, and is the best place to test the drop. You may even notice that your drop is less in the summer, since a leaner mixture is better then.

To check this, do your normal mag check, they pull the choke out about halfway, and do another mag check like that. If the results are different, it's your carbs not your ignition.

4000 RPM is the leanest range, and is the best place to test the drop. You may even notice that your drop is less in the summer, since a leaner mixture is better then.

Last edited:

Update, the carbs have been overhauled by Lockwood and reinstalled. The problem still exists to the same extent. I believe it to be an ignition issue. Any ideas about testing ignition components and procedures. Any input will help as the problem has been persisting for weeks now. Thank you.

I have done in flight ignition tests and everything seems fine. Its fine on the ground after the flight while doing a 4000 rpm test. Something is happening during the warmup from cold. One spark plug is just not firing on ignition B during the first attempt at the ignition test.

Piper J3

Well Known Member

You installed all new plugs? if so, you might consider replacing the spark plug caps. Just a feeling the 5 ohm resistor gets mutilated when pulling off the soft rubber caps - just a gut feeling. I installed these... https://www.ebay.com/itm/NGK-Spark-...536496&hash=item440f7f83d6:g:cekAAOSwcP5c13Bx

Last edited:

ChrisRV12new

I'm New Here

I have this exact same issue. Any resolve? It started a few weeks ago. Replaced spark plugs and used Walker P12. Did not resolve issue. Flight ignition tests drop only 80 RPM. Initial warm up from cold engine 4000 RPM drop 400-500 and very rough running engine.

Also noticed very high fuel burn first hour of flight. 7.0 gph at 8300ft. Then very suddenly, it dropped to normal 4.4 gph. I don’t know if this is related?

Are the plugs being fouled on cold taxi out? Really started when it got cold last few weeks.

New RV12 owner, very much still learning the aircraft. Any insight would be greatly appreciated.

Also noticed very high fuel burn first hour of flight. 7.0 gph at 8300ft. Then very suddenly, it dropped to normal 4.4 gph. I don’t know if this is related?

Are the plugs being fouled on cold taxi out? Really started when it got cold last few weeks.

New RV12 owner, very much still learning the aircraft. Any insight would be greatly appreciated.

Rough running on first run up

I think your right on some plugs being fouled from a long taxi. I used to have the same problem. If your carb’s are balanced, then I’ve found if you keep the time between start and run up as short as you can it helps.(2300 + rpm’s till oil 120 degrees) Do the run up even if it’s not where you normally do it, then do it again before take off. Hope it helps.

I think your right on some plugs being fouled from a long taxi. I used to have the same problem. If your carb’s are balanced, then I’ve found if you keep the time between start and run up as short as you can it helps.(2300 + rpm’s till oil 120 degrees) Do the run up even if it’s not where you normally do it, then do it again before take off. Hope it helps.

Whity1231$

I think you are right about some plugs fouling from a long taxi. I used to have the same problem and found that if I keep the time from start to run up as short as possible it helped a lot.(2300 + rpm’s till oil 120 degrees) Then run up even if not where you normally do, then again before take off.Hope it helps. Also make sure your carb’ have been balanced.

I think you are right about some plugs fouling from a long taxi. I used to have the same problem and found that if I keep the time from start to run up as short as possible it helped a lot.(2300 + rpm’s till oil 120 degrees) Then run up even if not where you normally do, then again before take off.Hope it helps. Also make sure your carb’ have been balanced.

ChrisRV12new

I'm New Here

What spark plug connector did you purchase? I printed off section 74 of the heavy maintenance manual. Looks like the spark plug boots screw on and off? I’m really new at this so my questions are pretty basic.

What I am having trouble understanding is why my RV 12 ignition check works after takeoff? 80 RPM drop in the air. On the ground, cold engine warmed up to 120 degree F oil temp and I get 500 RPM drop and feels like at least one cylinder not firing. Confused.

Good luck with your fix, hope it works. I will look at doing the same thing. Replaced all 8 spark plugs. Old ones were black and sooty.

Thanks- Chris

What I am having trouble understanding is why my RV 12 ignition check works after takeoff? 80 RPM drop in the air. On the ground, cold engine warmed up to 120 degree F oil temp and I get 500 RPM drop and feels like at least one cylinder not firing. Confused.

Good luck with your fix, hope it works. I will look at doing the same thing. Replaced all 8 spark plugs. Old ones were black and sooty.

Thanks- Chris

So the new spark plug boot and plugs did not help. The boots are NGK VD05FMH to match the originals, I got them Amazon. I also switched the ignition modules and found that the issue is still there when the A ignition is turned off during the check. This means that the issue is staying with the particular cylinder (#2). Has anyone switched coils for diagnostic purposes? I’m not how you would switch the coils on that cylinder for another cylinder to see if the issue remains.

ChrisRV12new

I'm New Here

Thank you for the update. I’m working today but looking at getting some flying in Sunday-Thursday. I’m located at KPLU, Pacific Northwest winter weather so VFR conditions little bit rare.

We pretty much have the same issue. I’m going to collect more data this week as we work through this issue.

I’m planning to take the Rainbow Aviation course for LSA repairmen Feb 6-7. Should get some good info there. Also have a team building an RV12 6 hangars down along with a college on field flying a Tecnam twin. Could start asking them for advice as well. Good luck, please let me know if you find anything.

-Chris

We pretty much have the same issue. I’m going to collect more data this week as we work through this issue.

I’m planning to take the Rainbow Aviation course for LSA repairmen Feb 6-7. Should get some good info there. Also have a team building an RV12 6 hangars down along with a college on field flying a Tecnam twin. Could start asking them for advice as well. Good luck, please let me know if you find anything.

-Chris

ChrisRV12new

I'm New Here

Is it possible the spark plugs are fouling on the taxi out from cold engine? Mine started few weeks ago when it got cold. And it tests properly in flight. 80 RPM drop. I’m going to print off the carb section of the heavy maintenance manual to learn.

You just got yours back from Lockwood so they seem like they would be in perfect condition. Is it possible to adjust the lean/rich mixture for the taxi out?

Right now I think my plugs are fouling. But I don’t know for sure.

You just got yours back from Lockwood so they seem like they would be in perfect condition. Is it possible to adjust the lean/rich mixture for the taxi out?

Right now I think my plugs are fouling. But I don’t know for sure.

Piper J3

Well Known Member

I still believe the rough running syndrome when doing initial ignition check at 4000 RPM is carb related and not ignition. Capacitive Discharge Ignition (CDI) is a very hot spark and will operate plugs that are in less than pristine condition.

What I think you’re looking at is carbs running rich most likely from taxing where float bowl level rises when the floats are jumping around. Carb float bowl on an airplane engine is a very violent place. This is especially true on Rotax 4-cyl where carbs are mounted at extreme distance from engine centerline. As the engine shakes the carbs mounted at the cylinder heads move significantly and float bowl level is hard to control.

All that said… When you taxi out and get ready to perform 4000 RPM ignition drop test, the float level is most likely very high and maybe even overflowing the bowl. As you run for a period of time at this higher RPM two things happen – excess fuel in float bowl is consumed establishing a correct fuel level and the engine begins to run smoother because the mixture is leaning and becoming more correct.

This also explains why RPM ignition drop test performed in the air shows no problem. Float level is easily maintained when engine is running high RPM in cruise flight. Engine runs smooth at high RPM and any burp of higher float level is consumed instantly at 5 gallon/hour flow rate.

Bottom line is everything is Hunky-Dory.

What I think you’re looking at is carbs running rich most likely from taxing where float bowl level rises when the floats are jumping around. Carb float bowl on an airplane engine is a very violent place. This is especially true on Rotax 4-cyl where carbs are mounted at extreme distance from engine centerline. As the engine shakes the carbs mounted at the cylinder heads move significantly and float bowl level is hard to control.

All that said… When you taxi out and get ready to perform 4000 RPM ignition drop test, the float level is most likely very high and maybe even overflowing the bowl. As you run for a period of time at this higher RPM two things happen – excess fuel in float bowl is consumed establishing a correct fuel level and the engine begins to run smoother because the mixture is leaning and becoming more correct.

This also explains why RPM ignition drop test performed in the air shows no problem. Float level is easily maintained when engine is running high RPM in cruise flight. Engine runs smooth at high RPM and any burp of higher float level is consumed instantly at 5 gallon/hour flow rate.

Bottom line is everything is Hunky-Dory.

ChrisRV12new

I'm New Here

That makes sense and is lining up with what I'm seeing on the line. Thank you for taking the time to write that explanation Jim.

-Cheers! Chris

-Cheers! Chris

At this point I do not think it is carb related. I replaced the B ignition spark plugs. Right after I started it the first time with the new plugs I did a quick mag check and found the drop much larger and rougher with the A ignition off. I believe this shows that the condition exists at start up and not a fouled plug during warmup issue.

trecool44, How did you balance your carbs? What equipment did you use and the method?

I have my money on your issue rooted in a bad balance.

Some facts; the top plugs fire more efficiently because of their placement in the cylinder head. The front cylinders do not get the same mixture as the rear cylinders because of the longer intake manifold. I tell you this to help you understand why a carb imbalance can cause a differential mag drop. look at which plugs are responsible for the lower drop.

I had a very similar problem at 2500 RPM, a vibration and the left ignition had a much bigger drop than the right. This means the right ignition, coils, or plugs are the problem. After replacing the spark plugs, cutting back plug wires, swapping the ignition modules inputs & output plugs. It was traced to the only common denominator was the 2 coils and their related spark plugs.

Because of an unrelated issue I had to pull the prop and upon replacing it I did a dynamic balance and changed the floats to Marvel Schebler MS80-430, (got tired of the Rotax game). The last thing to do was a carb balance (which I was sure was fine). I ran the engine first to warm up and the problem still existed. After balancing the carbs it was all gone, vibration and difference in ignition drops.

MANY "experts" told me they thought my problem was fuel related, I was insistent it was electrical, I almost bought a coil pack, glad I didn't.

I have my money on your issue rooted in a bad balance.

Some facts; the top plugs fire more efficiently because of their placement in the cylinder head. The front cylinders do not get the same mixture as the rear cylinders because of the longer intake manifold. I tell you this to help you understand why a carb imbalance can cause a differential mag drop. look at which plugs are responsible for the lower drop.

I had a very similar problem at 2500 RPM, a vibration and the left ignition had a much bigger drop than the right. This means the right ignition, coils, or plugs are the problem. After replacing the spark plugs, cutting back plug wires, swapping the ignition modules inputs & output plugs. It was traced to the only common denominator was the 2 coils and their related spark plugs.

Because of an unrelated issue I had to pull the prop and upon replacing it I did a dynamic balance and changed the floats to Marvel Schebler MS80-430, (got tired of the Rotax game). The last thing to do was a carb balance (which I was sure was fine). I ran the engine first to warm up and the problem still existed. After balancing the carbs it was all gone, vibration and difference in ignition drops.

MANY "experts" told me they thought my problem was fuel related, I was insistent it was electrical, I almost bought a coil pack, glad I didn't.

I found this it may be if some help;

-I have a bad mag drop, what do I do?

First determine if you have a carburetor problem or an ignition problem;

(WHAT?? Yes, the Rotax 9 series dual carb system can confuse the owner as a carb problem may show up as a high mag drop on one ignition system) Procedure:

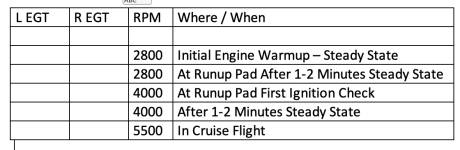

Run the engine at 4000rpm (approx 1700 prop rpm) and perform a mag check. Record the numbers.

Slowly pull the choke out half way, the RPM should rise about 200 RPM.

Try the mag drop and record numbers.

If the problem is worse or better the carbs are suspect.

If there is no change the carbs are not suspect, you likely have an ignition

problem.

Source;

https://www.rotax-owner.com/pdf/ROAN%20FAQs.pdf#page4

-I have a bad mag drop, what do I do?

First determine if you have a carburetor problem or an ignition problem;

(WHAT?? Yes, the Rotax 9 series dual carb system can confuse the owner as a carb problem may show up as a high mag drop on one ignition system) Procedure:

Run the engine at 4000rpm (approx 1700 prop rpm) and perform a mag check. Record the numbers.

Slowly pull the choke out half way, the RPM should rise about 200 RPM.

Try the mag drop and record numbers.

If the problem is worse or better the carbs are suspect.

If there is no change the carbs are not suspect, you likely have an ignition

problem.

Source;

https://www.rotax-owner.com/pdf/ROAN%20FAQs.pdf#page4

ChrisRV12new

I'm New Here

Great, thank you everyone. Weather looks good tomorrow for KPLU flight. Going to try that rotax info with the choke to test if it's carbs or ignition. Thanks for posting it.

ChrisRV12new

I'm New Here

Piper J3

Well Known Member

Taxi and flight test today were a success. I kept the power much higher during cold engine warm up.

Correct. Idle warm-up at higher speed is beneficial. I bring idle speed to ~ 2800 RPM as soon as engine starts.

• Cold engine runs smoother when speed is increased.

• Better for gearbox when engine runs smooth – no chattering.

• Smoother running is better for carb float level.

Let engine run ~3500 RPM for a minute or so prior to the 4000 RPM ignition drop test. This will normalize float levels that would otherwise contribute to large RPM drop.

Also, best to run fresh fuel. High-octane Mogas isn’t a big seller at gas stations, so it’s a little like a **** shoot when buying. I buy 93E10 for engine requiring 91 octane, so not much of a cushion there. Ethanol in the fuel is very volatile. The vented fuel tank allows air exchange. Alcohol will evaporate causing a reduction in octane, and because alcohol is hydroscopic, it will absorb moisture from the air which isn’t good either. If possible, use a Top Tier gas supplier.

Correct. Idle warm-up at higher speed is beneficial. I bring idle speed to ~ 2800 RPM as soon as engine starts.

Fast idle during cold warm up is a good idea but I wouldn't recommend RV-12 owners go above the 2500 RPM limitation when the oil temp is below 120 F.

This is to assure that since the oil pump has to suck oil out of the remote tank, that overly viscous (cold) oil doesn't ever cause a cavitation of the oil pump and the resultant bad things that could go with that.

I have performed the test with the choke on as suggested. I am getting the same drop and roughness so I believe I have an ignition issue. What are the tests I can do on the coils themselves? The issue seems to be getting worse, I had to run for a few minutes at 4500 to get it to smooth out. Thanks again.

Piper J3

Well Known Member

I have performed the test with the choke on as suggested. I am getting the same drop and roughness so I believe I have an ignition issue. What are the tests I can do on the coils themselves? The issue seems to be getting worse, I had to run for a few minutes at 4500 to get it to smooth out. Thanks again.

You very likely have carb and not ignition problem.

Follow post #30 and report back...

Carbs have been balanced and rechecked. Floats have been replaced and weighed before install. I’m still thinking coils or trigger coils.

I have never seen you mention anything about checking the fuel.

Have you tried different fuel? Do you know for sure it is fresh?

I have seen poor fuel cause strange issues, particularly in cold operating conditions.

We have non ethanol 93 delivered from a local oil company. I have not tried other fuel as the non-ethanol 93 is scarce around here. Hey deliver to 4 other customers in our community with no issues. I can’t completely discount fuel quality at this point. I really appreciate all the input from everyone here.

Piper J3

Well Known Member

NinerBikes

Well Known Member

We have non ethanol 93 delivered from a local oil company. I have not tried other fuel as the non-ethanol 93 is scarce around here. Hey deliver to 4 other customers in our community with no issues. I can’t completely discount fuel quality at this point. I really appreciate all the input from everyone here.

After doing lots of research on fuel quality and floats that end up failing, in Bing carb equipped motors, I am of the opinion that if you are turning over your fuel, going through a tankfull per month 12 to 15 gallons worth, Ethanol fuel is rarely a problem for floats. What is a problem is fuel providers that "dump" cosolvents in their gasoline as a way to get rid of a problem solvent when refining fuel, instead of paying for it's disposal. At least here, in CA, IMHO, the two worst fuel brands are Shell and Valero. Both their gas and their diesel fuel deliver about 8 to 10% less MPG's in all the fuel log fillups I"ve kept for my vehicles since about 1980. I don't know who the dumpster fire fuel makers or sellers are in Florida. Cosolvents are really "fluff" or filler in fuel, takes up volume in a gallon of gas, but really doesn't add much energy or HP to a gallon of gasoline. It's using your motor as an incinerator for a waste product, so to speak, from the refining process.

My point it, burn up what's in the plane, get a couple of 6 gallon fuel tanks and go buy some FRESH premium fuel at a busy fuel station that's not the two brands mentioned above. Don't buy fuel from the airport, for these tests.

See if your problem goes away with the fresh fuel. A lot of places say that their fuel is ethanol free... don't believe it, test it yourself, get an ethanol tester vial/ graduated cylinder and find out for yourself. https://www.amazon.com/Briggs-Strat...ds=ethanol+fuel+tester&qid=1611773623&sr=8-12

Last edited:

We have non ethanol 93 delivered from a local oil company. I have not tried other fuel as the non-ethanol 93 is scarce around here. Hey deliver to 4 other customers in our community with no issues. I can’t completely discount fuel quality at this point. I really appreciate all the input from everyone here.

How old is the gas once it’s in your aircraft. Auto fuel starts deteriorating after 30 days.

Piper J3

Well Known Member

Yes, try fresh Mogas. Search online for Top Tier suppliers. 93E10 is a common high-octane fuel recommended for Rotax 912. Ethanol is fine, no need for ethanol-free.

Years ago I had a conversation with a petrochemical engineer and he told me how off-brand suppliers get fuel that is refined from slop tank oil. This is oil that is culled from pipelines when different liquids are transported. It is oil that is at the interface where the liquids mix in the pipeline. His advice: stick with Top Tier suppliers…

Years ago I had a conversation with a petrochemical engineer and he told me how off-brand suppliers get fuel that is refined from slop tank oil. This is oil that is culled from pipelines when different liquids are transported. It is oil that is at the interface where the liquids mix in the pipeline. His advice: stick with Top Tier suppliers…

Art_N412SB

Member

trecool44, The front cylinders do not get the same mixture as the rear cylinders because of the longer intake manifold.

We have been having the same rough running issues. We were wondering why the plugs on our front cylinders were black and the aft cylinder plugs were clean. We did not realize that the front cylinders have a different fuel/air ratio due to their longer manifold distance. Thanks