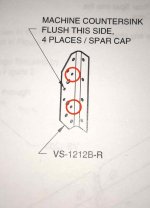

Well, I promised lots of questions a few months back and my first RV-12 kit finally arrived and it hasn't taken long for me to run into my first puzzle: I can't figure out how to do countersink a hole in tight quarters. On page 06-04, step 3 the instructions innocently say to countersink four holes, but two of the holes are next to a flange and my 1" diameter countersink cage doesn't come close to fitting. I don't see any narrower cages online, and I haven't found anyone else mentioning this problem. So how did you all manage to accomplish this step? I've attached the plan diagram and a photo of the actual part. The holes in question are 1/4" away from the flange.

Am I missing something obvious?

Thanks!

Am I missing something obvious?

Thanks!